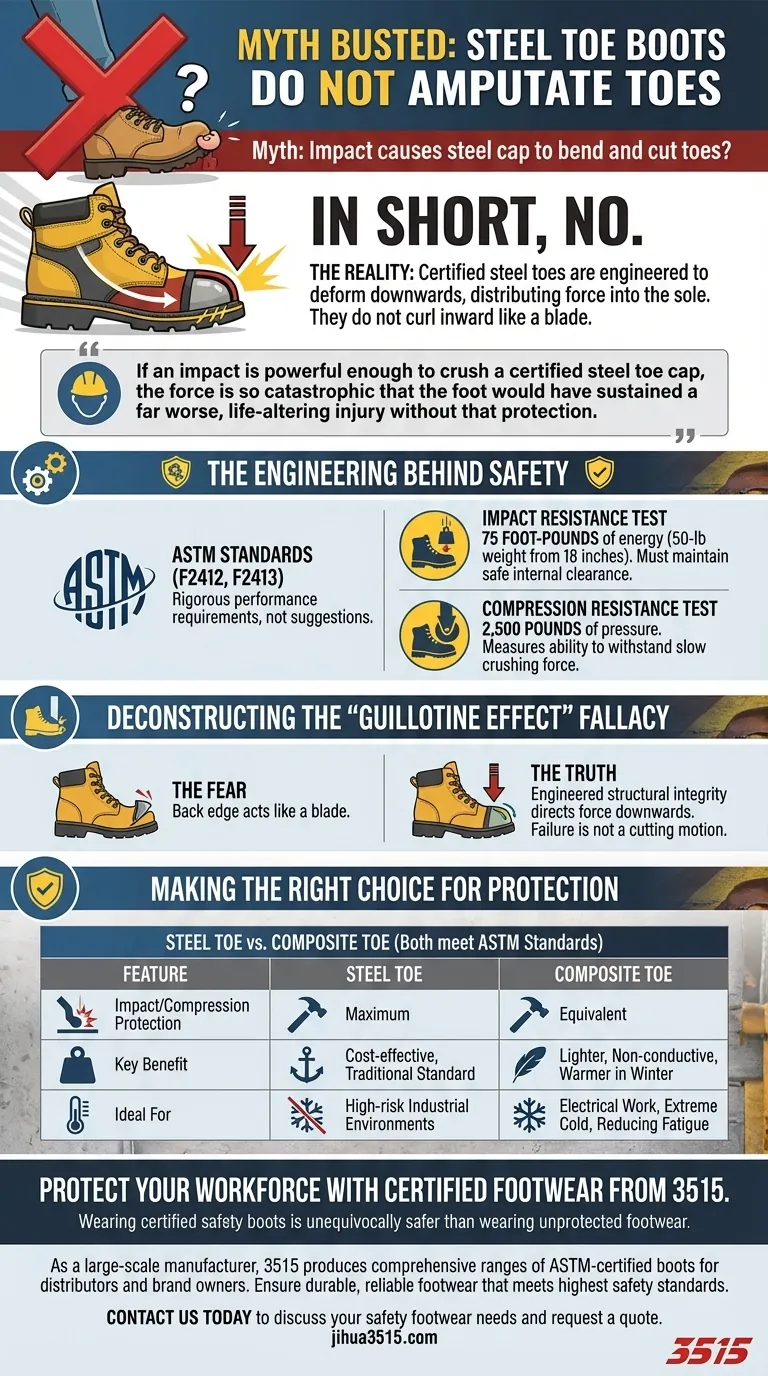

In short, no. The idea that an impact can cause a steel toe cap to bend in a way that amputates or severely injures your toes is a persistent myth. All regulated safety boots, including steel toe models, are engineered and tested to withstand significant impacts without collapsing or creating a cutting hazard.

The core issue isn't whether steel toe boots can fail, but understanding the immense, unsurvivable forces required to make them fail. If an impact is powerful enough to crush a certified steel toe cap, the force is so catastrophic that the foot would have sustained a far worse, life-altering injury without that protection.

The Engineering Behind Steel Toe Safety

To understand why this myth is false, we need to look at the standards and design principles governing safety footwear.

The Role of ASTM Standards

Safety boots sold in the United States must meet standards set by the ASTM International (specifically, ASTM F2412 and F2413). These standards are not suggestions; they are rigorous requirements for performance.

The two key tests for the toe cap are impact resistance and compression resistance.

How Impact Testing Works

A steel toe cap is tested by dropping a heavy weight onto it from a specified height. For the highest rating, this involves dropping a 50-pound weight from a height of 18 inches, creating 75 foot-pounds of impact energy.

During this test, the cap is allowed to deform, but it must maintain a specific minimum clearance height inside the boot. This clearance ensures there is enough space to prevent the cap from pinning or crushing the toes.

How Compression Testing Works

The compression test measures the toe cap's ability to withstand a slow, crushing force. For the highest rating, the boot must withstand 2,500 pounds of pressure before the toe cap's internal clearance drops below the minimum safe height.

This simulates the scenario of a heavy object, like a piece of machinery, slowly rolling onto the foot.

Deconstructing the Myth

The myth survives because it plays on a logical-sounding fear: metal bending under force. However, it overlooks the physics and the engineering standards in place.

The "Guillotine Effect" Fallacy

The fear is that the back edge of the steel cap could act like a blade upon impact. However, the cap is designed to deform in a way that directs the force down into the sole of the boot, not to curl inward and downward.

The shape of the cap is engineered for structural integrity. For it to fail in a cutting motion, the impact would need to be extraordinarily precise and powerful, far beyond what is typically encountered in survivable workplace accidents.

Force and Survivability

Consider the forces involved. A boot certified to withstand 2,500 pounds of compression is protecting against an immense load.

If an event occurs that generates enough force to completely defeat a certified steel toe cap, the level of trauma to the rest of the body would be the primary concern. The safety boot is the last line of defense in an incident that is already catastrophic. Without it, the injury would not be a possibility, but a certainty.

Understanding the Real-World Trade-offs

While the amputation myth is false, choosing the right safety toe material does involve practical considerations. The choice is less about catastrophic failure and more about daily use and specific job requirements.

Steel vs. Composite Toes

Steel toes are the traditional standard. They offer maximum protection against impact and compression and are often more cost-effective. Their primary drawback is weight and electrical conductivity.

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter, do not conduct electricity, and don't get as cold in winter. However, they can be bulkier than steel to achieve the same safety rating.

When Injury Can Still Occur

It's crucial to remember that safety boots protect against specific, tested hazards. An impact that strikes the foot behind the protective cap can still cause severe injury to the metatarsal bones. This is not a failure of the steel toe, but a limitation of its coverage area.

Making the Right Choice for Your Protection

Choosing the right boot means trusting the standards and matching the material to your environment.

- If your primary focus is maximum impact protection in a high-risk environment: A steel toe boot provides proven, reliable safety that meets the highest industry standards.

- If your primary focus is working around live electricity or in extreme cold: A composite toe boot offers equivalent certified protection without the risks of electrical conductivity or thermal transfer.

- If your primary focus is reducing fatigue from all-day wear: A lighter composite toe may be preferable, provided it meets the required ASTM safety rating for your job.

Ultimately, wearing a certified safety boot, whether steel or composite, is unequivocally safer than wearing unprotected footwear.

Summary Table:

| Safety Toe Feature | Steel Toe | Composite Toe |

|---|---|---|

| Key Benefit | Maximum impact/compression protection | Lighter, non-conductive, better for cold weather |

| ASTM Impact Test | Withstands 75 ft-lbs of energy | Meets same ASTM safety ratings |

| ASTM Compression Test | Withstands 2,500 lbs of pressure | Meets same ASTM safety ratings |

| Ideal For | High-risk industrial environments | Electrical work, cold climates, reducing fatigue |

Protect your workforce with certified safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified steel toe and composite toe boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive durable, reliable footwear that meets the highest safety standards, helping you prevent workplace injuries.

Contact us today to discuss your safety footwear needs and request a quote.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

People Also Ask

- How are steel and composite toe caps tested for safety? Discover the Uniform Standard

- What are the advantages of wearing steel toe shoes? Maximum Protection for Your Workforce

- What are the 5 main protections offered by steel toe boots? A Guide to Workplace Foot Safety

- What are the key benefits of modern steel toe boots? Achieve Maximum Safety & Durability

- Which occupations typically require steel toe boots? A Guide to Essential Foot Protection

- What are steel-toe boots and why are they important? Essential Foot Protection for High-Risk Work

- What are steel toe work boots and what is their primary purpose? Essential Foot Protection for Hazardous Work

- Does allowing employees to wear steel-toe rubber boots offsite exempt the employer from payment? Understand OSHA's specialty PPE rules.