In short, steel-toe boots are heavier than their composite-toe counterparts. However, this simple fact is often misleading. The protective toe cap accounts for a very small fraction of a boot's total weight, with materials for the sole, upper, and midsole playing a much larger role in how heavy the boot feels on your foot.

While composite toes offer a lighter-weight alternative, the decision hinges on a crucial trade-off: balancing marginal comfort gains against the superior impact and compression resistance that only steel can provide.

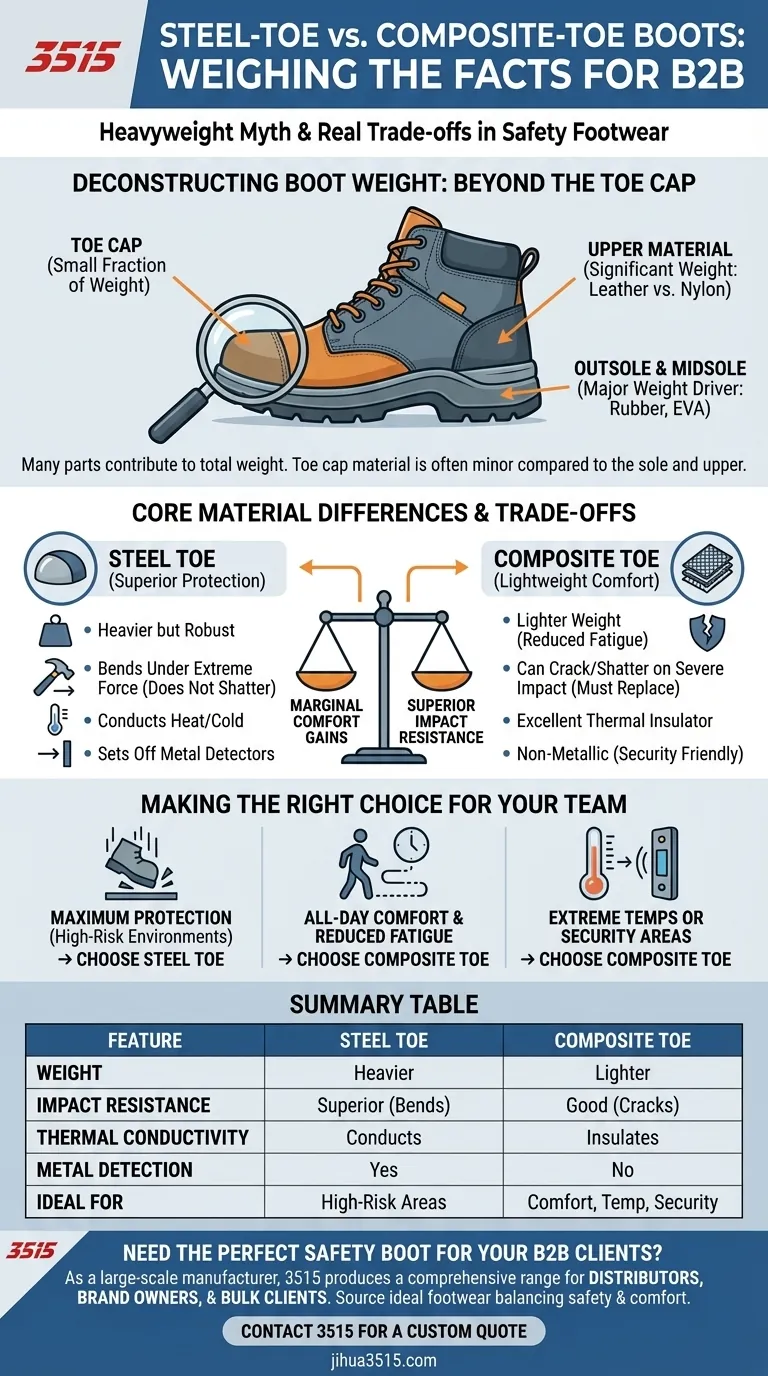

Deconstructing Boot Weight: Beyond the Toe Cap

Many people focus exclusively on the toe cap material when judging boot weight, but this is a common oversight. The total weight is a sum of all its parts, and the cap is often not the most significant contributor.

The Role of the Toe Cap

The toe cap itself, whether steel or composite, is only a few ounces. While a composite cap is lighter than a steel one, the difference might only be 30-40%. This small variance can easily be overshadowed by other design choices.

The Real Drivers of Weight

The heaviest components of a work boot are typically the outsole and midsole. A thick, dense rubber sole designed for slip resistance and durability will add far more weight than a lightweight EVA foam midsole. Likewise, a full-grain leather upper will be heavier than one made from synthetic nylon.

Core Material Differences: Steel vs. Composite

The choice between steel and composite materials has implications that go far beyond weight, directly impacting safety, durability, and comfort in different environments.

The Strength of Steel

Steel has superior resistance to compression and impact. When subjected to extreme force that exceeds its safety rating, steel is designed to bend and deform, but not crack or shatter. This provides a predictable and robust layer of protection in high-risk environments.

The Profile of Composite

Composite toes are made from non-metal materials like carbon fiber, Kevlar, or specialized plastics. To achieve the same safety rating as steel, a composite cap must often be slightly thicker or bulkier, which can affect the fit and profile of the boot's toe box.

Understanding the Trade-offs

Choosing the right safety boot requires an objective look at the benefits and drawbacks of each material, as the best choice depends entirely on your work environment and daily tasks.

Durability and Impact Resistance

Steel's primary advantage is its durability. It can withstand higher loads before failing. Composite toes, while meeting ASTM safety standards, can crack or shatter upon severe impact. After a single significant impact event, a composite-toe boot must be replaced.

All-Day Comfort and Fatigue

The lighter weight of a composite-toe boot can reduce fatigue over a long workday. For workers who walk many miles per shift, this small but cumulative weight savings can be a meaningful factor in overall comfort.

Thermal Conductivity

Steel readily conducts heat and cold. In extreme temperature environments, this can lead to discomfort. Composite materials are excellent insulators, making them a far better choice for those working in very hot or freezing conditions.

Metal Detection

Because they contain no metal, composite-toe boots will not set off metal detectors. This is a critical feature for workers in security-sensitive fields like aviation, law enforcement, or nuclear facilities.

Making the Right Choice for Your Job

To select the correct boot, prioritize the specific demands of your work environment over a single metric like weight.

- If your primary focus is maximum protection against crushing and falling objects: Steel toe is the safer choice due to its ability to bend rather than shatter under extreme loads.

- If your primary focus is all-day comfort and reduced leg fatigue: A composite-toe boot is likely a better option, provided your work doesn't involve extreme impact risks.

- If you work in extreme heat, cold, or pass through metal detectors: Composite toe is the clear winner for its thermal insulation and non-metallic properties.

By understanding these core differences, you can select the safety boot that truly supports the demands of your job.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Weight | Heavier | Lighter |

| Impact/Compression Resistance | Superior (Bends under extreme force) | Good (Can crack/shatter) |

| Thermal Conductivity | Conducts heat/cold (less insulation) | Excellent insulator |

| Metal Detection | Will set off detectors | Will not set off detectors |

| Ideal For | Maximum protection in high-risk environments | All-day comfort, extreme temperatures, security-sensitive areas |

Need the Perfect Safety Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including both steel-toe and composite-toe models.

We can help you source the ideal footwear that balances safety, comfort, and durability for your specific industry needs. Get a quote for your next order today!

Contact 3515 for a Custom Quote

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do aluminium toe caps compare to steel toe caps in terms of weight and temperature? Choose the Best for Comfort & Safety

- What is the primary purpose of steel toe cap safety boots? Ultimate Toe Protection for Hazardous Work

- When should steel toe boots be replaced? Protect Your Feet from Costly Workplace Injuries

- How can you optimize the fit of steel toe boots for better comfort? A Complete Guide to Custom Fit

- What are the advantages of alloy toe work shoes? Lighter Weight, Superior Comfort

- Are steel toe boots comfortable for casual wear? Find Your Perfect Balance of Style & Safety

- Does allowing employees to wear steel-toe rubber boots offsite exempt the employer from payment? Understand OSHA's specialty PPE rules.

- Why might someone choose a composite toe boot over a steel toe boot? Lighter, Safer, and More Comfortable.