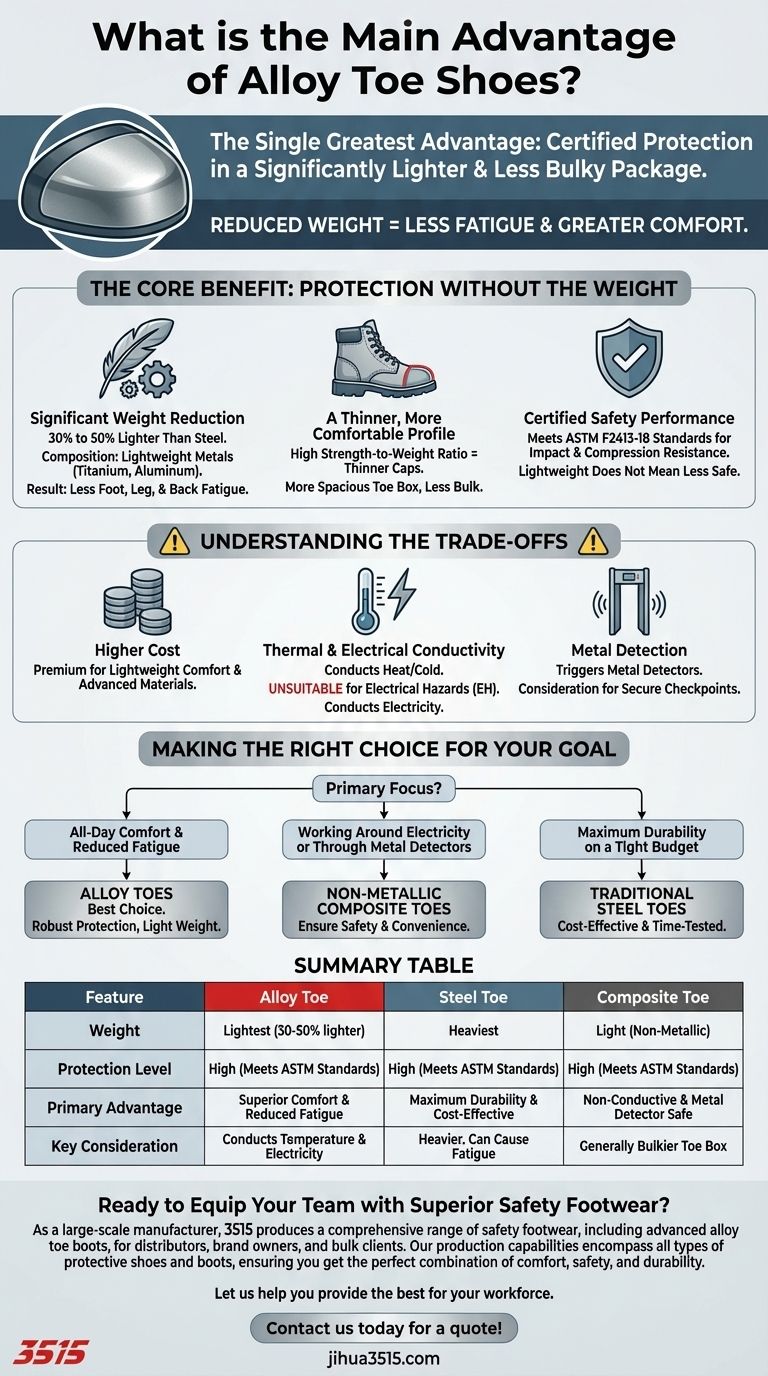

The single greatest advantage of alloy toe shoes is that they provide certified impact and compression protection, comparable to steel, but in a significantly lighter and less bulky package. This reduction in weight directly translates to less foot fatigue and greater comfort over a long workday.

Alloy safety toes represent a modern engineering solution to a classic problem: how to get the strength of metal without the weight penalty of traditional steel. They offer a superior balance of comfort and protection for many, but are not the right choice for every work environment.

The Core Benefit: Protection Without the Weight

The primary reason to choose alloy toe footwear is to reduce the physical strain of wearing safety shoes all day. This is achieved through advanced metallurgy and design.

Significant Weight Reduction

Alloy toes are typically crafted from lightweight metals like titanium, aluminum, and other metallic elements. This composition makes them between 30% and 50% lighter than their steel counterparts.

This weight difference is critical. Over thousands of steps in a single shift, the reduced mass dramatically lessens fatigue in your feet, legs, and back.

A Thinner, More Comfortable Profile

Because of their high strength-to-weight ratio, alloy safety caps can be made thinner than steel caps while still meeting the same safety standards.

This creates a more spacious toe box inside the shoe. The result is a less bulky, more comfortable fit that feels closer to a standard boot, with more room for your toes to move naturally.

Certified Safety Performance

It is crucial to understand that "lightweight" does not mean "less safe." Alloy safety toes are held to the same rigorous industry standards as all other safety footwear.

They must meet the ASTM F2413-18 standards for impact and compression resistance, ensuring they provide the necessary protection against falling objects and crushing forces.

Understanding the Trade-offs

While alloy toes offer compelling advantages, they come with a specific set of limitations that are essential to consider before making a purchase.

Higher Cost

The advanced materials and manufacturing processes used to create alloy toes typically make them more expensive than traditional steel toe or even some composite toe options. You are paying a premium for the lightweight comfort.

Thermal and Electrical Conductivity

Like any metal, alloy toes will conduct temperature. They will get cold in cold weather and hot in hot weather, which can be a source of discomfort.

More importantly, they also conduct electricity. This makes them an unsuitable choice for electricians or anyone working in environments with a significant risk of electrical shock. Look for an "EH" (Electrical Hazard) rating if this is a concern.

Metal Detection

Because they are metallic, alloy toe shoes will trigger metal detectors. This is a key consideration for workers who must pass through security checkpoints frequently, such as in airports, government buildings, or secure facilities.

Making the Right Choice for Your Goal

Selecting the correct safety toe depends entirely on the demands of your job. There is no single "best" option, only the best option for your specific environment and priorities.

- If your primary focus is all-day comfort and reducing fatigue: Alloy toes are likely your best choice, providing robust protection without the heavy weight of steel.

- If your primary focus is working around electricity or through metal detectors: You must choose non-metallic composite toes to ensure safety and convenience.

- If your primary focus is maximum durability on a tight budget: Traditional steel toes remain the most cost-effective and time-tested option for heavy-duty work.

Ultimately, choosing the right safety toe is about precisely matching the material's properties to the demands of your workday.

Summary Table:

| Feature | Alloy Toe | Steel Toe | Composite Toe |

|---|---|---|---|

| Weight | Lightest (30-50% lighter) | Heaviest | Light (Non-Metallic) |

| Protection Level | High (Meets ASTM Standards) | High (Meets ASTM Standards) | High (Meets ASTM Standards) |

| Primary Advantage | Superior Comfort & Reduced Fatigue | Maximum Durability & Cost-Effective | Non-Conductive & Metal Detector Safe |

| Key Consideration | Conducts Temperature & Electricity | Heavier, Can Cause Fatigue | Generally Bulkier Toe Box |

Ready to Equip Your Team with Superior Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear, including advanced alloy toe boots, for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots, ensuring you get the perfect combination of comfort, safety, and durability.

Let us help you provide the best for your workforce.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What is the role of high-definition USB cameras in the detection of safety shoes? Enhancing Site Safety with HD Clarity

- What are the advantages of using leather in safety shoes? Superior Durability & Breathability

- What comfort features are included in safety shoes? Key Elements for All-Day Wear

- Are there firefighter boots available for children? Discover Safe & Fun Costume Boots

- What materials are commonly used for outsoles in safety boots? A Guide to Durability, Grip, and Comfort

- How do safety shoes promote stability and ankle support? Secure Your Stance on Any Terrain

- What is the scenario described in the letter regarding safety toe protective footwear? Understanding Employer Payment Obligations

- What protective functions do industrial safety shoes provide in petroleum environments? Secure Your Workers' Health