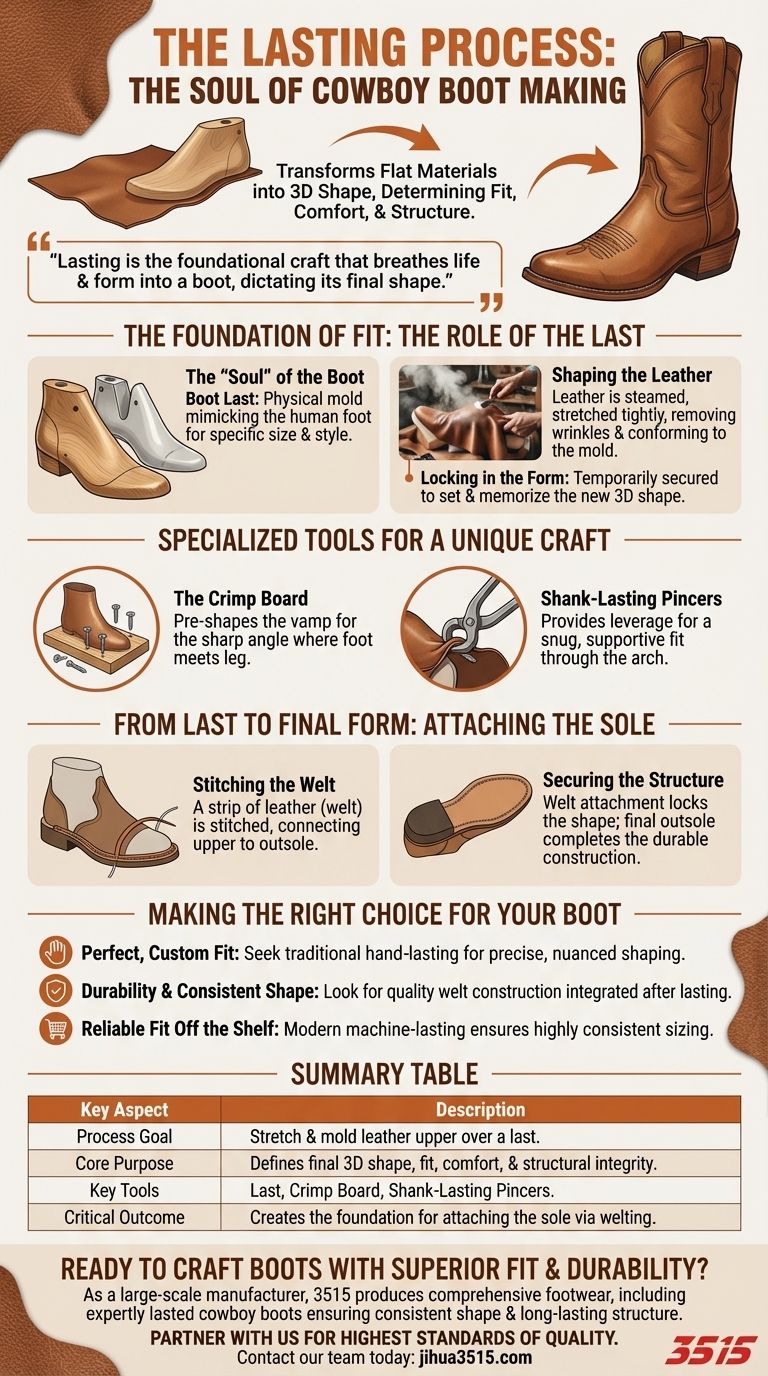

The lasting process is the critical stage in cowboy boot making where the leather upper is meticulously stretched and molded around a foot-shaped form called a "last." This step transforms flat materials into the three-dimensional shape of the boot, fundamentally determining its fit, comfort, and structure before the sole is attached.

Lasting is not merely a step in assembly; it is the foundational craft that breathes life and form into a boot, dictating its final shape and ensuring it conforms to the contours of a human foot.

The Foundation of Fit: The Role of the Last

The entire structure and comfort of a cowboy boot begin with the last. It is the solid foundation upon which the boot is built.

The "Soul" of the Boot

A boot last is a physical mold, traditionally carved from wood but now often made of plastic, that mimics the shape of a human foot. Each size and style of boot requires a specific last to achieve its intended shape, from the toe box to the heel.

Shaping the Leather

During the lasting process, the boot's leather upper is steamed or dampened to make it pliable. Craftsmen then use specialized tools to stretch and pull this leather tightly over the last, removing all wrinkles and ensuring it conforms perfectly to the mold's shape.

Locking in the Form

Once stretched, the leather is temporarily secured to the last with nails or adhesive. It is then left to dry and set for a period of time, allowing the leather's fibers to memorize their new three-dimensional form.

Specialized Tools for a Unique Craft

While cowboy boot making shares tools with general shoemaking, its unique construction demands specialized equipment for the lasting process.

The Crimp Board

Many bootmakers use crimp boards (or blocker boards) and crimp screws to pre-shape the vamp—the front part of the boot covering the top of the foot. This pre-stretching helps create the sharp, distinctive angle where the foot meets the leg, a hallmark of a quality cowboy boot.

Shank-Lasting Pincers

Specialized pliers, known as shank-lasting pincers, are used to grip and pull the tough leather around the shank area (the arch of the foot). This tool provides the leverage needed to create a snug, supportive fit through the boot's arch.

From Last to Final Form: Attaching the Sole

The lasting process concludes by preparing the boot for its sole, which gives the footwear its final structure.

Stitching the Welt

After the upper has fully taken the shape of the last, a strip of leather called the welt is stitched to the edge of the upper. This component acts as the crucial connection point between the upper and the outsole.

Securing the Structure

Attaching the welt locks the lasted shape of the upper into place. The final outsole is then stitched to the welt, completing the boot's primary construction and making it a durable, cohesive unit.

Making the Right Choice for Your Boot

Understanding the lasting process empowers you to appreciate the quality and fit of a cowboy boot.

- If your primary focus is a perfect, custom fit: Seek out bootmakers who emphasize traditional hand-lasting, as this manual process allows for the most precise and nuanced shaping to a specific foot.

- If your primary focus is durability and consistent shape: Look for boots with a quality welt construction, as this feature is directly integrated after a successful lasting process and ensures a solid build.

- If your primary focus is finding a reliable fit off the shelf: Recognize that modern machine-lasting creates highly consistent boots, ensuring that a size 10 from a trusted brand will fit the same way every time.

Ultimately, the care taken during the lasting process is the invisible source of a great boot's comfort and character.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Goal | Stretch and mold the leather upper over a foot-shaped form (last). |

| Core Purpose | Defines the boot's final 3D shape, fit, comfort, and structural integrity. |

| Key Tools | Last, Crimp Board, Shank-Lasting Pincers. |

| Critical Outcome | Creates the foundation for attaching the sole via welting. |

Ready to Craft Boots with Superior Fit and Durability?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including expertly lasted cowboy boots that guarantee consistent shape, exceptional comfort, and long-lasting structure.

Partner with us to ensure your footwear meets the highest standards of quality.

Contact our team today to discuss your manufacturing needs and how we can bring your boot designs to life.

Visual Guide

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are street or casual motorcycle boots and their features? A Guide to Stylish, Safe Riding Footwear

- Why is a cushioned footbed important in office work shoes? Boost All-Day Comfort & Productivity

- What materials are recommended for business casual shoes? Choose the Right Material for a Polished Look

- What are the key features of high-quality leather in shoes? Invest in Durability and a Perfect Fit

- What tips can help get the best price on casual dress shoes? Smart Strategies for Value & Savings

- What is the connection between Chukka boots and World War II? Discover the History of the Iconic Desert Boot

- What distinguishes chukka boots from desert boots? Your Guide to Style & Function

- What makes wingtip casual shoes practical? Versatile Style Meets Everyday Comfort