At its core, the difference is simple. "Safety toe" is the broad category of footwear designed with a reinforced toe cap to protect you from impact and compression. "Steel toe" is a specific type of safety toe that uses a steel cap, existing alongside other materials like composite and aluminum.

The real question isn't just about the definition, but which material is right for your job. While steel toe is the traditional standard, the best choice depends entirely on your work environment's specific hazards, from electrical risks to temperature extremes.

The "Safety Toe" Umbrella

A boot earns the "safety toe" classification by meeting specific performance standards for protection. It’s a functional category, not a material one.

The Standard for Protection

To be considered a true safety boot, the protective toe cap must withstand a significant impact. For example, the common ASTM F2413-18 standard requires protection against impacts of 75 foot-pounds and compressive loads of 2,500 pounds.

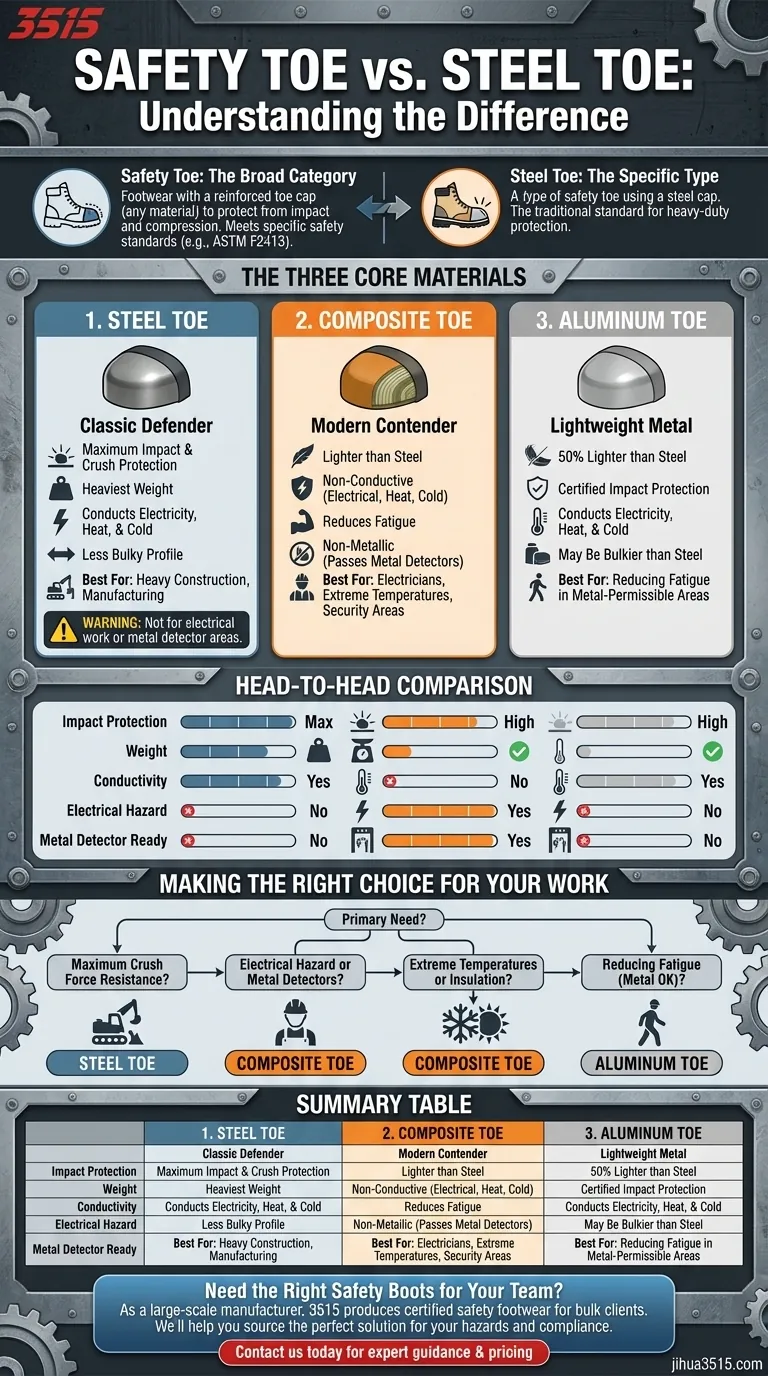

The Three Core Materials

While other variations exist, the safety toe category is dominated by three primary materials, each with distinct properties:

- Steel: The original and most common material.

- Composite: Non-metallic materials like carbon fiber, Kevlar, or plastic.

- Aluminum: A lighter metal alternative to steel.

A Head-to-Head Material Comparison

Understanding the characteristics of each material is crucial for selecting the right boot for your specific needs.

Steel Toe: The Classic Defender

Steel toes offer the highest level of protection against impact and crushing forces. They are the traditional choice for heavy-duty work environments.

Because steel is so strong, the cap can be made thinner than other materials, resulting in a less bulky boot profile.

Composite Toe: The Modern Contender

Composite toes are made from non-metallic materials. This makes them significantly lighter than steel, reducing foot fatigue over a long day.

Their key advantage is that they do not conduct electricity, heat, or cold, making them the superior choice for electricians or those working in extreme temperatures.

Aluminum Toe: The Lightweight Metal

Aluminum toes provide the same level of impact protection as steel but are up to 50% lighter. This makes them a great option for reducing fatigue.

Like steel, they conduct electricity and temperature. To achieve the required strength, the aluminum cap is often thicker than a steel cap, which can create a bulkier fit.

Understanding the Trade-offs

No single material is universally superior. Your choice involves balancing protection against environmental factors and comfort.

Protection vs. Weight

Steel offers the most robust defense against extreme crushing forces, but it is also the heaviest option. For jobs in heavy construction or manufacturing, this trade-off is often necessary.

Composite and aluminum toes significantly reduce the boot's weight, which can lessen fatigue. They meet the same official safety standards, but steel provides a greater margin of safety for impacts that exceed those standards.

The Hazard of Conductivity

A critical and often overlooked factor is conductivity. Because steel and aluminum are metals, they readily transfer temperature. In cold weather, this can make your feet dangerously cold; in high-heat environments, it can be just as hazardous.

More importantly, their electrical conductivity makes them completely unsuitable for electricians or anyone working near live circuits. Composite toes are the only safe option in these scenarios.

Workplace Logistics

Many high-security workplaces, from airports to power plants, require passing through metal detectors. Wearing steel or aluminum toe boots in these environments is impractical.

Composite boots are non-metallic and will not trigger these security systems, saving significant time and hassle.

Making the Right Choice for Your Work

To select the ideal boot, match the material's properties to the primary demands and hazards of your job.

- If your primary focus is maximum impact protection: Steel toe boots remain the gold standard for resisting heavy crushing forces in environments like heavy construction.

- If your primary focus is working around electricity or metal detectors: Composite toe boots are the essential choice due to their non-metallic, non-conductive properties.

- If your primary focus is reducing fatigue in a metal-permissible environment: Aluminum toe boots offer a lightweight alternative to steel without sacrificing certified protection.

- If your primary focus is comfort in extreme temperatures: Composite toes provide superior insulation against both heat and cold, preventing thermal transfer to your feet.

Choosing the right boot begins with a clear understanding of your daily hazards.

Summary Table:

| Toe Type | Key Characteristics | Best For |

|---|---|---|

| Steel Toe | Maximum impact/crush protection; conducts temperature/electricity; heavy | Heavy-duty work (construction, manufacturing) |

| Composite Toe | Non-metallic, non-conductive; lighter; insulates against temperature | Electricians, extreme temperatures, metal detector areas |

| Aluminum Toe | Lighter than steel; same certified protection; conducts temperature/electricity | Reducing fatigue in metal-permissible environments |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We can help you source the perfect boots—whether steel, composite, or aluminum toe—to match your specific job hazards and ensure worker safety and compliance.

Contact us today for expert guidance and competitive pricing on bulk orders.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Why are precision metal processing and industrial heat treatment equipment essential in the production of toe caps?

- What are the advantages of steel toe protection in work boots? Unmatched Safety & Durability

- What materials are used for toe protection in work boots? Steel vs. Composite Toe Cap Guide

- Are steel or composite toe boots OSHA approved? Decoding the Standards for Workplace Safety

- What are the most common types of safety toe caps? Choose the Right Protection for Your Job

- What is the history of steel toe work boots? From German Invention to Modern Safety Standard

- What are the advantages of steel toe caps? Unmatched Impact & Puncture Protection

- How should one decide whether to wear steel-toe boots at work? Assess Your Risks for Optimal Foot Safety