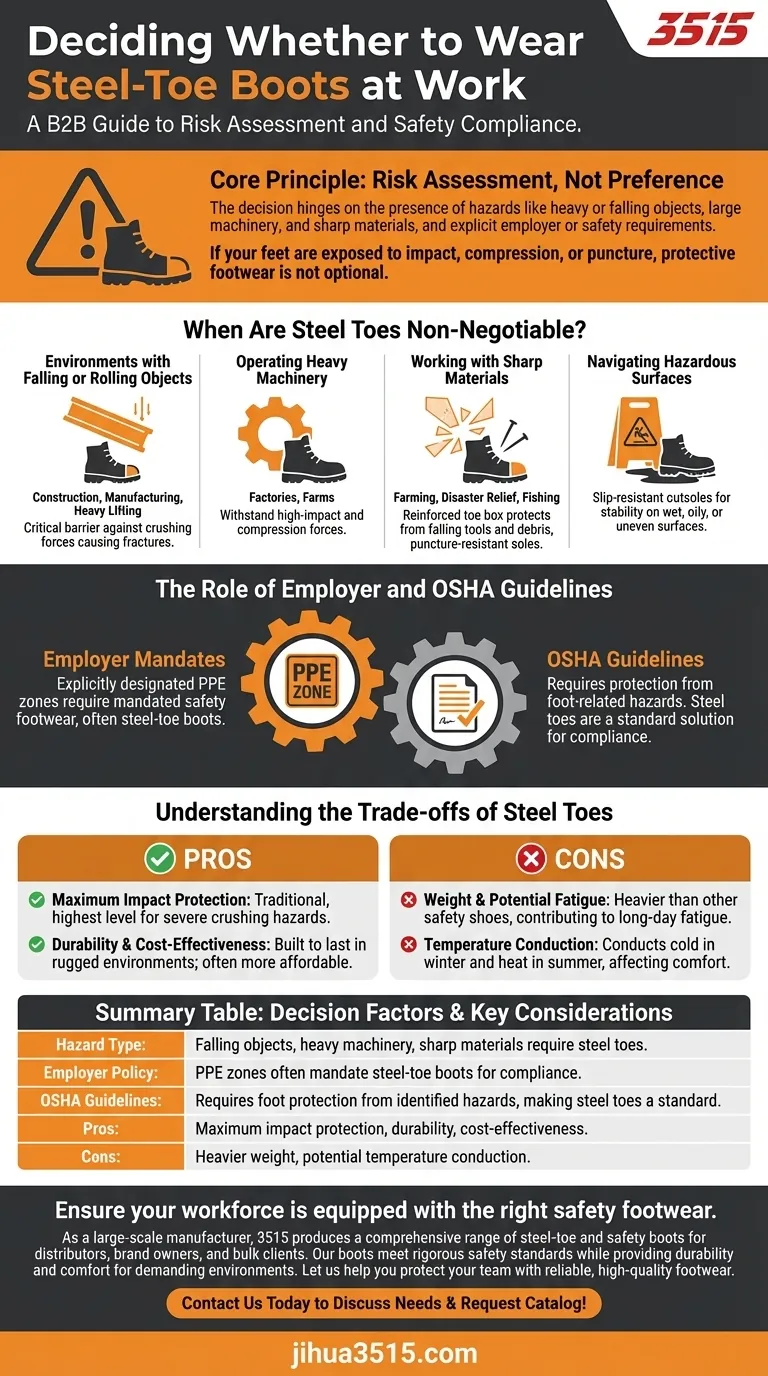

To decide whether to wear steel-toe boots, you must perform a risk assessment of your specific work environment. The decision hinges on the presence of hazards like heavy or falling objects, large machinery, and sharp materials, as well as any explicit requirements mandated by your employer or safety regulations.

The core principle is simple: your decision isn't a matter of preference but a direct response to the specific, identified hazards of your job. If your feet are exposed to potential impact, compression, or puncture injuries, protective footwear is not optional.

When Are Steel Toes Non-Negotiable?

Certain work environments present clear and significant risks that make protective footwear, like steel-toe boots, an essential piece of equipment.

Environments with Falling or Rolling Objects

If you work in construction, manufacturing, or any role involving heavy lifting, the risk of an object falling or rolling onto your feet is high. A steel toe cap acts as a critical barrier against crushing forces that could cause severe fractures or other foot damage.

Operating Heavy Machinery

Jobs that involve operating or working near heavy machinery, such as in factories or on large farms, require robust foot protection. Steel toes are designed to withstand the high-impact and compression forces associated with this type of equipment.

Working with Sharp Materials

Industries like farming, disaster relief, and even fishing can expose workers to sharp objects on the ground. Steel-toe boots often come with puncture-resistant soles, but the reinforced toe box also provides critical protection from falling tools, hooks, or debris.

Navigating Hazardous Surfaces

While not unique to steel toes, many boots with this feature are designed for overall safety. This includes slip-resistant outsoles that are crucial for maintaining stability on wet, oily, or uneven surfaces, which are common in industrial settings.

The Role of Employer and OSHA Guidelines

Your personal risk assessment is only one part of the equation. Official regulations and company policies often make the decision for you.

Understanding Employer Mandates

Many companies explicitly designate certain areas as PPE (Personal Protective Equipment) zones. If your job requires you to enter these areas, you must wear the mandated safety footwear, which very often includes steel-toe boots.

Following OSHA's Lead

The Occupational Safety and Health Administration (OSHA) provides clear guidelines for workplace safety. While they don't mandate a specific brand or type, they do require employers to ensure workers are protected from foot-related hazards, making steel toes a standard solution for compliance.

Understanding the Trade-offs of Steel Toes

While their protective qualities are unmatched in certain scenarios, steel-toe boots come with specific characteristics you must consider.

Pro: Maximum Impact Protection

Steel provides the highest level of protection against impact and compression. It is the traditional, time-tested material for safeguarding feet from the most severe crushing hazards.

Pro: Durability and Cost-Effectiveness

Steel is an exceptionally durable material. Boots made with steel toe caps are built to last in rugged environments and are often more affordable than those made with composite materials.

Con: Weight and Potential Fatigue

The primary drawback of steel is its weight. Steel-toe boots are heavier than other safety shoes, which can contribute to foot fatigue over a long workday.

Con: Temperature Conduction

Because steel is a metal, it conducts temperature. In very cold environments, the steel can become cold, and in hot environments, it can retain heat, potentially affecting comfort.

Making the Right Choice for Your Job

Your final decision should be based on a clear-eyed assessment of your daily tasks and environment.

- If your primary focus is working in construction, manufacturing, or disaster relief: Steel toes are the standard and likely required for their superior protection against heavy impact and compression.

- If your primary focus is farming or manual labor with sharp objects: Protective footwear is essential, and steel-toe boots offer a robust and durable solution.

- If your primary focus is compliance with employer policy: You must wear the PPE mandated for your work area, which frequently specifies steel-toe protection.

- If your primary focus is finding a balance of safety and comfort with moderate risk: Evaluate if lighter-weight composite-toe boots meet your workplace's specific safety assessment and requirements.

Choosing the right footwear is a foundational step in ensuring your personal safety on the job.

Summary Table:

| Decision Factor | Key Consideration |

|---|---|

| Hazard Type | Falling objects, heavy machinery, sharp materials require steel toes. |

| Employer Policy | PPE zones often mandate steel-toe boots for compliance. |

| OSHA Guidelines | Requires foot protection from identified hazards, making steel toes a standard. |

| Pros | Maximum impact protection, durability, cost-effectiveness. |

| Cons | Heavier weight, potential temperature conduction. |

Ensure your workforce is equipped with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of steel-toe and safety boots for distributors, brand owners, and bulk clients. Our boots are designed to meet rigorous safety standards while providing durability and comfort for demanding environments. Let us help you protect your team with reliable, high-quality footwear. Contact us today to discuss your specific needs and request a catalog!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Is there any truth to the myth about steel toe boots causing toe injuries upon impact? Debunking Common Safety Concerns

- How can one prevent blisters when wearing steel toe boots? A Complete Guide to Pain-Free Workdays

- What is the importance of choosing the right size for steel toe boots? Avoid Injury and Boost Productivity

- Are steel toe boots inherently bad for your feet? Debunking Myths for Workplace Safety

- What are the key features of a work boot? Essential Protection for Hazardous Work Environments