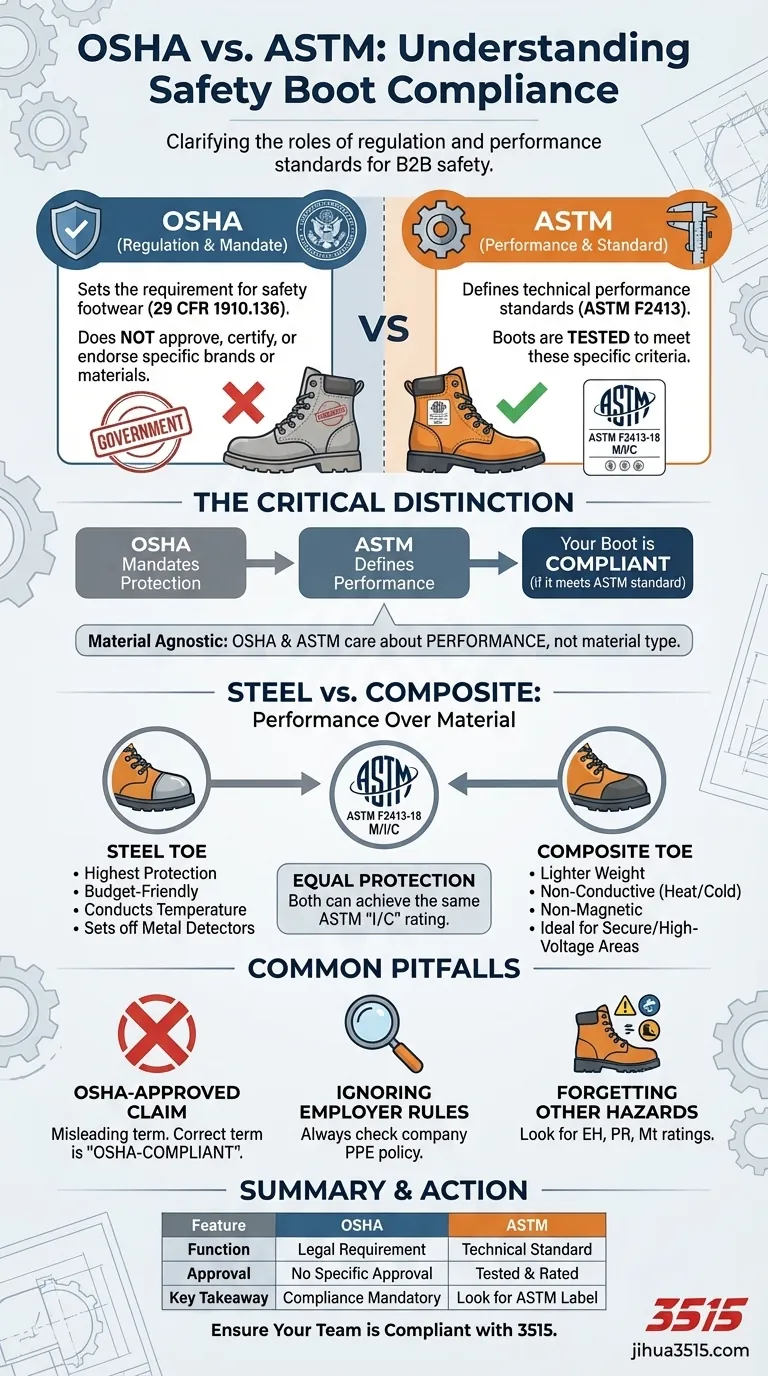

Contrary to a common misconception, the Occupational Safety and Health Administration (OSHA) does not approve, certify, or endorse any specific brand or type of safety boot, including steel toe or composite toe. Instead, OSHA mandates that employers ensure protective footwear is used in workplaces with specific hazards. This footwear must meet or exceed the technical performance standards set by a recognized consensus organization, primarily ASTM International.

The critical distinction is that OSHA sets the requirement for safety, while independent organizations like ASTM set the performance standard that footwear must meet. Your boot is compliant if it meets the appropriate ASTM standard for your specific workplace hazards, regardless of the toe material.

The Roles of OSHA vs. ASTM Explained

To select compliant footwear, you must understand the difference between the government regulator and the standards organization. They play distinct but complementary roles in ensuring your safety.

OSHA's Role: Setting the Mandate

OSHA is a federal regulatory agency. Its job is to ensure safe and healthful working conditions by setting and enforcing standards.

The relevant OSHA standard for footwear, 29 CFR 1910.136, states that employers must require employees to use protective footwear when they are working in areas where there is a danger of foot injuries. It doesn't specify the brand or material, only the need for protection.

ASTM's Role: Defining the Standard

ASTM International is a global organization that develops and publishes voluntary consensus technical standards for a wide range of products, including safety footwear.

The key standard here is ASTM F2413. This standard establishes the minimum performance requirements for protective footwear, including impact resistance (I), compression resistance (C), and other specialized protections.

How to Identify a Compliant Boot

A compliant safety boot will have a label inside that clearly states it conforms to the ASTM F2413 standard.

The label will look something like this: ASTM F2413-18 M/I/C. This code indicates it meets the 2018 version of the standard for a Male (M) boot, with both Impact (I) and Compression (C) resistance for the toe area.

Steel vs. Composite: Performance Over Material

Both OSHA and ASTM are material-agnostic. The standards care about whether the boot can pass specific tests, not what the protective toe cap is made of. Both steel and composite materials can achieve the same level of ASTM-rated protection.

The Focus is on the Protection Rating

A steel toe boot and a composite toe boot that are both rated for "I/C" on the ASTM label provide the same minimum level of protection against impact and compression forces.

The choice between them comes down to other factors specific to your job, environment, and personal preference.

When to Choose Steel Toe

Steel is the traditional material for safety toes. It often provides the highest level of protection and can be found in more budget-friendly options. Its primary drawback is that it conducts temperature and will set off metal detectors.

When to Choose Composite Toe

Composite toes are made from non-metal materials like carbon fiber, Kevlar, or plastic. They are lighter, do not conduct heat or cold, and will not set off metal detectors, making them ideal for certain secure or high-voltage environments.

Understanding the Common Pitfalls

Navigating safety standards can be confusing. Avoiding these common mistakes will ensure you are both safe and compliant.

Misinterpreting "OSHA-Approved"

Any marketing claim of a boot being "OSHA-approved" is incorrect and misleading. The correct term is "OSHA-compliant," which means the boot meets the performance standards (like ASTM F2413) that OSHA requires employers to follow.

Ignoring Employer-Specific Rules

Your employer is responsible for conducting a hazard assessment of your workplace. Based on this assessment, they will determine the specific protections you need. Always check your company's Personal Protective Equipment (PPE) policy first.

Forgetting Other Hazards

Toe protection is just one aspect of foot safety. The ASTM standard includes codes for other critical protections you may need.

Look for ratings like EH (Electrical Hazard), PR (Puncture Resistance), and Mt (Metatarsal Guard) on the boot's label if your job exposes you to those risks.

Making the Right Choice for Your Job

Your final decision should be based on a clear understanding of your work environment and company policy.

- If your primary focus is compliance: Look for the ASTM F2413 label inside the boot and confirm the required protection ratings (e.g., I, C, EH) with your safety manager.

- If you work in extreme cold or heat: A composite toe is generally a better choice as it does not conduct temperature like metal.

- If you pass through metal detectors frequently: A composite toe boot will save you significant time and hassle.

- If your job involves a high risk of crushing or falling objects: Both steel and composite toes with the proper ASTM rating are equally protective, but steel is the time-tested standard.

Ultimately, selecting the right safety boot begins with understanding your specific workplace hazards, not by searching for a non-existent OSHA approval stamp.

Summary Table:

| Feature | OSHA's Role | ASTM's Role |

|---|---|---|

| Function | Sets the legal requirement for protective footwear. | Defines the technical performance standards (e.g., ASTM F2413). |

| Approval | Does NOT approve or certify specific boots. | Boots are tested and rated to meet ASTM standards. |

| Key Takeaway | Compliance is mandatory; look for the ASTM label inside the boot. | The label (e.g., ASTM F2413-18 M/I/C) confirms protection levels. |

Ensure Your Team is Fully Compliant and Protected

Navigating OSHA and ASTM standards can be complex, but having the right safety footwear shouldn't be. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant steel toe and composite toe boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring you get durable, comfortable, and fully compliant boots tailored to your specific workplace hazards.

Let us help you equip your workforce with confidence. Contact our team today to discuss your requirements and receive a customized solution.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- How do aluminium toe caps compare to steel toe caps in terms of weight and temperature? Choose the Best for Comfort & Safety

- What is the primary function of Martensitic 1200 grade steel in UHSS toe caps? Achieve Slim, Lightweight Protection

- Do moc toe boots have steel toe? Get Durable, Safety-Compliant Footwear

- What features do steel toe boots offer besides protection? Unlock All-Day Comfort and Enhanced Safety

- How does the weight of steel-toe boots compare to composite-toe boots? Uncover the Real Trade-Offs

- What industries are safety toe work boots best suited for? Protect Your Feet in High-Risk Environments

- How much weight can steel toe work boots withstand? Unpacking the 3,372 lb. Safety Standard

- According to OSHA, when are steel toe boots required in the workplace? A Guide to Compliance