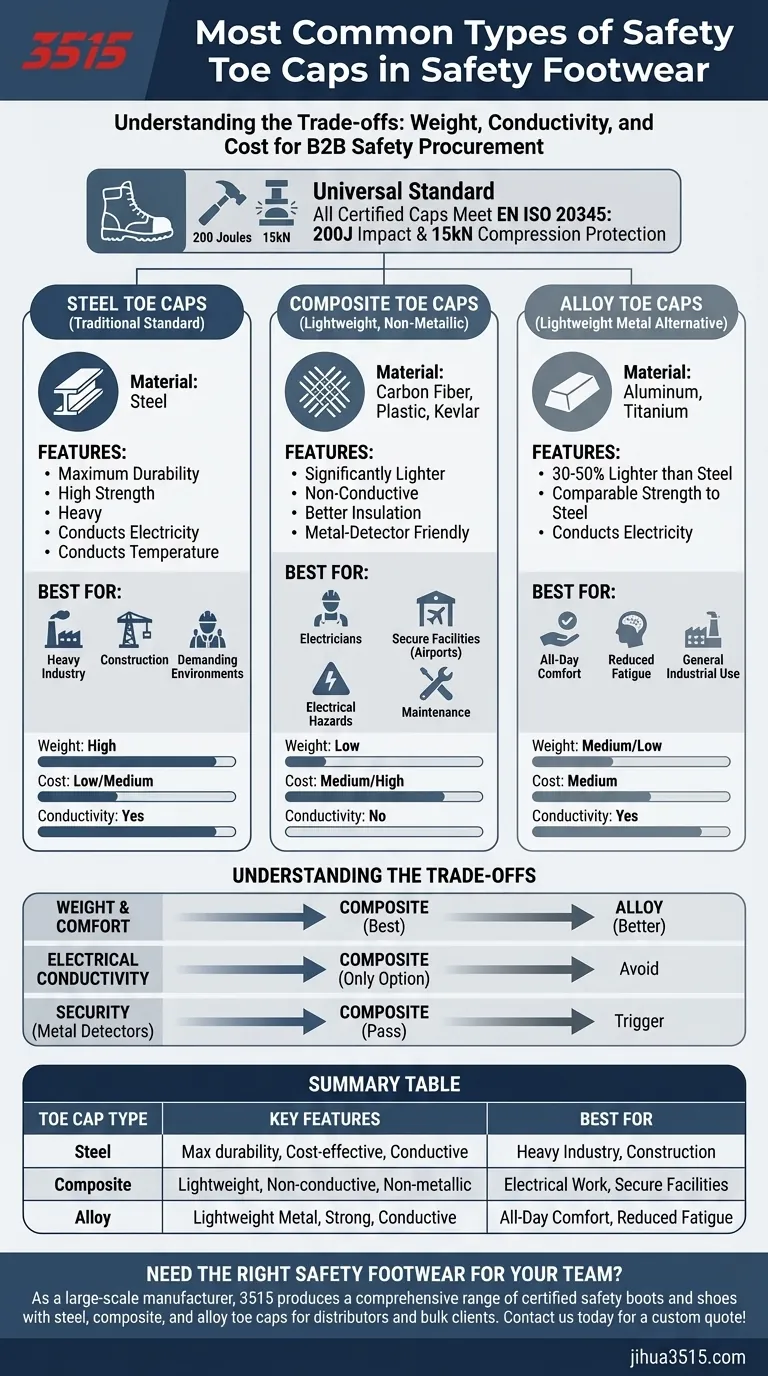

At its core, safety footwear relies on three primary types of protective toe caps: steel, composite, and alloy. While all are designed to shield your feet from serious injury, the material used has significant implications for weight, comfort, and suitability for specific work environments.

The most critical takeaway is that while all certified safety toe caps meet the same minimum impact and compression standards, the choice of material—steel, composite, or alloy—presents a fundamental trade-off between weight, conductivity, and cost.

The Baseline for Protection

Before comparing materials, it's essential to understand the universal standard they must all meet. This ensures a baseline level of safety, regardless of the material.

### The EN ISO 20345 Standard

A protective toe cap in certified safety footwear is engineered to withstand a significant amount of force.

It must resist a drop test impact of 200 Joules and a static compression force of 15 kilonewtons (kN). This ensures protection against both falling objects and crushing hazards.

### All Materials Meet the Standard

Whether the toe cap is made from steel, aluminum, or advanced plastics, it must pass these same rigorous tests. The difference between them is not in the minimum level of safety but in their other physical properties.

A Breakdown of Toe Cap Materials

Each material offers a distinct set of advantages and disadvantages, making it better suited for certain jobs and environments.

### Steel Toes: The Traditional Standard

Steel is the original material for safety toes and remains a highly popular choice for its exceptional strength.

It offers robust protection against heavy impacts and sharp objects, making it a reliable option for demanding environments like construction and manufacturing.

### Composite Toes: The Lightweight, Non-Metallic Option

Composite toe caps are crafted from non-metallic materials like carbon fiber, plastic, or Kevlar.

Their primary advantages are being significantly lighter than steel and their inability to conduct electricity. This makes them the ideal choice for electricians or anyone working in environments with electrical hazards. They also do not conduct heat or cold well, offering better insulation.

### Alloy Toes: The Lightweight Metal Alternative

Alloy toe caps are made from lightweight metals such as aluminum or titanium.

They provide a middle ground between steel and composite. They offer protection comparable to steel but at a reduced weight, often being 30-50% lighter. However, like steel, they are still conductive.

Understanding the Trade-offs

Choosing the right toe cap requires balancing protection against the practical needs of your daily work.

### Weight and Comfort

For workers who are on their feet all day, weight is a major factor in reducing fatigue.

Composite and alloy toes offer a significant weight advantage over traditional steel toes, contributing to greater overall comfort.

### Electrical Conductivity

This is a non-negotiable safety consideration in certain professions.

Composite toes are the only option that is non-conductive, making them mandatory for electricians and some maintenance roles. Both steel and alloy conduct electricity and should be avoided in these situations.

### Metal Detectors and Security

In environments like airports, secure facilities, or nuclear plants, passing through metal detectors is a daily routine.

Footwear with composite toe caps will not trigger these detectors, saving significant time and hassle.

Making the Right Choice for Your Environment

Your specific job function and work environment should be the ultimate guide in your decision.

- If your primary focus is maximum durability in heavy industrial or construction settings: Steel toes offer proven, cost-effective, and robust protection.

- If your primary focus is electrical safety or passing through metal detectors: Composite toes are the only suitable and practical choice.

- If your primary focus is balancing strong protection with all-day comfort and less fatigue: Alloy toes provide a lightweight metal alternative to steel.

Ultimately, understanding the properties of each toe cap material empowers you to select footwear that provides not just safety, but also comfort and practicality for your specific needs.

Summary Table:

| Toe Cap Type | Key Features | Best For |

|---|---|---|

| Steel | Maximum durability, cost-effective, conductive | Heavy industry, construction |

| Composite | Lightweight, non-conductive, non-metallic | Electrical work, secure facilities |

| Alloy | Lightweight metal, strong protection, conductive | All-day comfort, reduced fatigue |

Need the right safety footwear for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes with steel, composite, and alloy toe caps for distributors, brand owners, and bulk clients. We ensure your workforce has the perfect blend of protection, comfort, and compliance. Contact us today for a custom quote!

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- Why is Production Capacity (Mcap) a core parameter in safety shoe contracts? Optimize Supply and Mitigate Risk