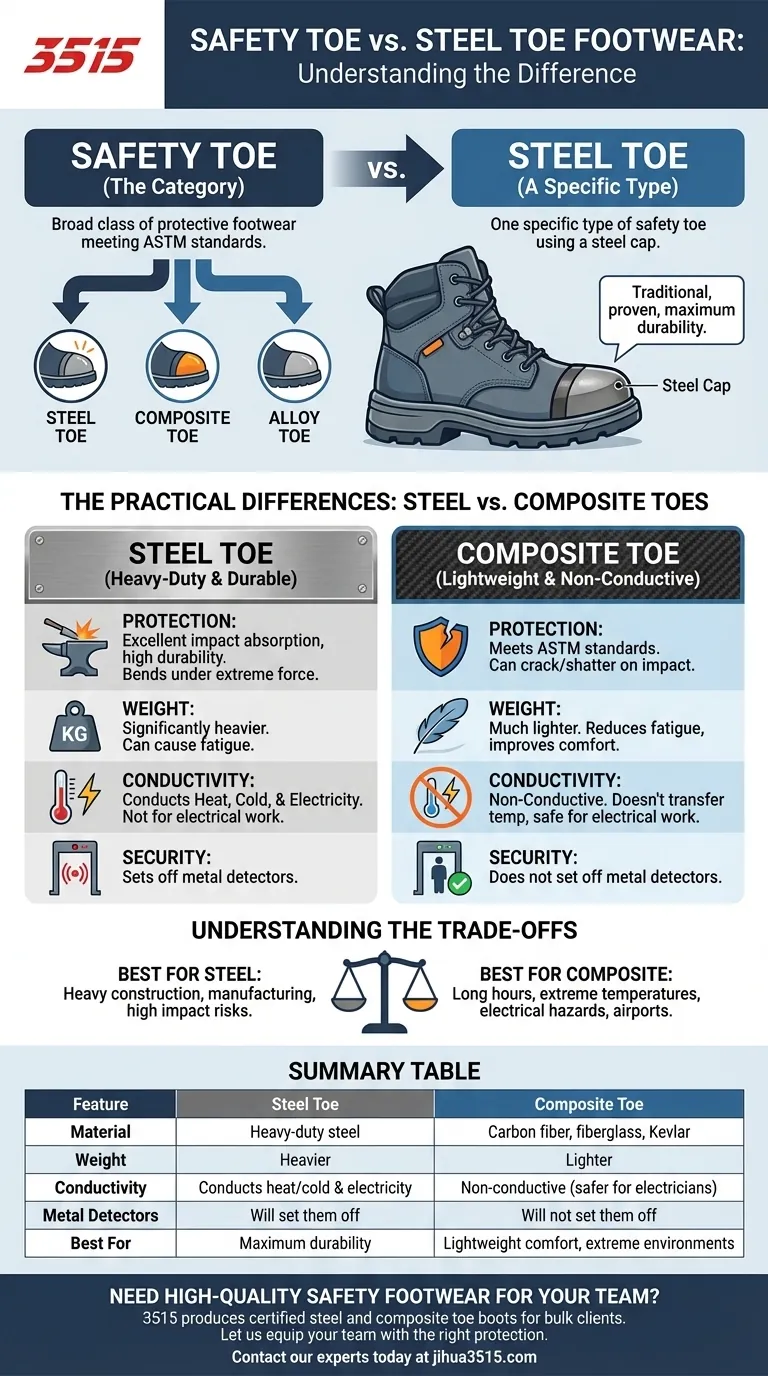

The fundamental difference is one of category versus type. "Safety toe" is the broad term for any footwear with a reinforced toe that meets specific ASTM safety standards. A "steel toe" is simply one specific type of safety toe, where the protective cap is made from heavy-duty steel.

While people often use the terms interchangeably, they are not the same. "Safety toe" refers to the overall class of protective footwear, which includes caps made of steel, composites, or alloy. The critical choice isn't between "safety" and "steel," but between the different materials used to achieve that safety rating.

The Core Distinction: Category vs. Material

The confusion between these terms arises from steel's long history as the original and most common material for protective footwear. However, modern advancements have introduced new options.

What Defines a Safety Toe?

A safety toe is a general classification for any boot or shoe with a protective cap in the toe area.

This cap must be tested and certified to meet the standards set by the American Society for Testing and Materials (ASTM F2413). These standards specify requirements for impact and compression resistance, ensuring the footwear protects your toes from specific hazards.

Safety toe caps can be made from several materials, including steel, specialized aluminum alloys, or non-metallic composite materials like carbon fiber, fiberglass, or Kevlar.

What Defines a Steel Toe?

A steel toe is a specific type of safety toe where the protective cap is made of steel.

For decades, steel was the only option, making the term synonymous with jobsite safety. It remains a popular choice due to its proven track record for maximum durability and strength.

The Practical Differences: Steel vs. Composite Toes

Both steel and composite toe boots that carry an ASTM rating provide the same minimum level of certified protection. The real difference lies in their material properties, which create distinct advantages depending on your work environment.

Protection and Durability

Steel is known for its ability to bend and absorb energy under extreme force, often withstanding impacts far beyond the minimum ASTM requirement. It is exceptionally durable.

Composite toes provide the required protection but can crack or shatter if they sustain an impact that exceeds their design limits. After a significant impact, a composite toe boot must be replaced.

Weight and All-Day Comfort

Steel is significantly heavier than composite materials. This added weight can contribute to foot fatigue over a long workday.

Composite toes are much lighter, making them a preferred choice for workers who spend a lot of time walking or standing, as they can noticeably improve comfort.

Thermal and Electrical Conductivity

Steel is a conductor. It readily transfers cold and heat, making steel toe boots less comfortable in extreme temperature environments. It also conducts electricity, posing a risk for electricians.

Composite materials are non-conductive. They do not transfer cold or heat and will not conduct electricity, making them ideal for work in very hot or cold conditions and essential for those working around live circuits.

Convenience at Security Checkpoints

Steel toe footwear will reliably set off metal detectors. This can be a daily inconvenience for workers who must pass through security screenings.

Composite toes are non-metallic and will not trigger metal detectors, offering a clear advantage for those working in secured facilities like airports or power plants.

Understanding the Trade-offs

Choosing the right material involves balancing performance, comfort, and environmental needs. Neither option is universally superior; they are simply different tools for different jobs.

The Case for Steel

Steel's primary advantage is its reputation for ultimate strength and durability. In environments with a high risk of extremely heavy falling or rolling objects, such as heavy construction or manufacturing, steel is often seen as the most reliable choice.

The Case for Composite

Composite's key advantages are its light weight and non-conductivity. For workers who value comfort, walk long distances, or work in extreme temperatures or near electrical hazards, composite is the clear winner. The convenience of passing through metal detectors is an added bonus.

Making the Right Choice for Your Goal

Your specific job hazards and daily activities should dictate your choice.

- If your primary focus is maximum impact resistance and proven durability in a heavy-duty environment: A traditional steel toe boot is your most reliable option.

- If your primary focus is lightweight comfort for long hours on your feet: A composite toe will significantly reduce fatigue and improve your overall comfort.

- If your primary focus is working in extreme temperatures or around electrical hazards: A non-conductive composite toe is the safest and most appropriate choice.

Ultimately, the best protective footwear is the one that correctly matches the unique demands of your job.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Material | Heavy-duty steel | Carbon fiber, fiberglass, or Kevlar |

| Weight | Heavier | Lighter |

| Conductivity | Conducts heat/cold & electricity | Non-conductive (safer for electricians) |

| Metal Detectors | Will set them off | Will not set them off |

| Best For | Maximum durability in heavy-duty environments | Lightweight comfort, extreme temperatures, electrical work |

Need High-Quality Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the proven durability of steel toe boots or the lightweight, non-conductive advantages of composite toe boots, we have the production capabilities and expertise to meet your needs.

Let us help you equip your team with the right protection.

Contact our experts today for a consultation and to discuss your specific requirements.

Visual Guide

Related Products

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the key differences in conductivity between steel and composite toe caps? Choose the Safer, More Comfortable Option

- What are the disadvantages of wearing steel-toe boots? Heavy Weight, Discomfort & Safety Risks

- What is a steel toe boot and how is it constructed? A Guide to Maximum Protection

- What industries require steel-toe boots? Protect Your Workforce from Common Hazards

- How do steel toe boots compare to composite toe boots? Choose the Right Toe for Your Job

- What are the benefits of steel toe caps in work boots? Achieve Maximum Protection for Heavy-Duty Work

- What are the key benefits of modern steel toe boots? Achieve Maximum Safety & Durability

- Which occupations typically require steel toe boots? A Guide to Essential Foot Protection