At its core, the difference is simple: insulated boots contain a layer of material designed to trap heat and keep your feet warm in cold conditions, while non-insulated boots do not. Insulated boots are built for thermal protection and temperature regulation, while non-insulated boots prioritize breathability, lighter weight, and flexibility for moderate weather or high-exertion activities.

The decision between insulated and non-insulated boots is not merely about warmth. It's about matching the right tool to your specific environment and activity level to ensure comfort, safety, and performance.

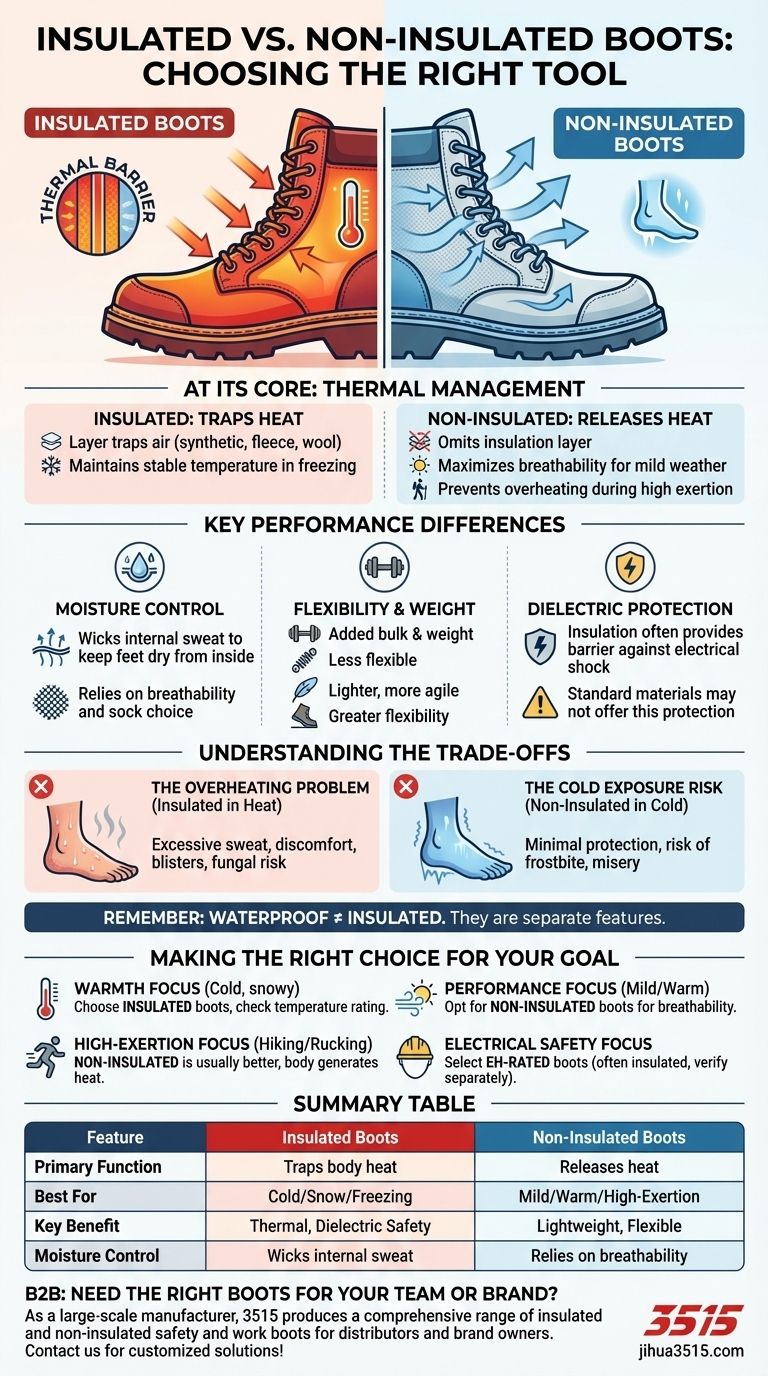

The Primary Function: Thermal Management

The most significant distinction between these two types of footwear is how they handle temperature. This difference dictates their intended use and effectiveness.

How Insulation Works

Insulated boots use materials like synthetic fibers, fleece, or wool to create a thermal barrier. This layer traps air, which is a poor conductor of heat, preventing the warmth your body generates from escaping and stopping the cold from penetrating.

The goal is to maintain a stable, comfortable temperature around your foot, even when the external environment is freezing.

When Insulation is Essential

Insulated footwear is the non-negotiable choice for static or low-activity work in cold, snowy, or icy conditions. Without it, your feet are vulnerable to discomfort and serious cold-related injuries like frostbite.

The Role of Non-Insulated Boots

Non-insulated boots are designed for three-season use (spring, summer, fall) or for high-output activities like hiking in milder winter climates. By omitting the insulation layer, they allow heat and moisture (sweat) to escape more effectively, preventing your feet from overheating.

Beyond Warmth: Key Performance Differences

While temperature is the primary factor, the presence or absence of insulation impacts other critical aspects of a boot's performance.

Moisture Control

Properly engineered insulated boots are designed not just to keep external moisture out, but to manage the sweat your feet produce. They help wick this moisture away from the skin to keep you dry from the inside, as dampness dramatically accelerates heat loss.

Non-insulated boots, while often waterproof, rely more on breathability and sock choice to manage internal moisture.

Flexibility and Weight

Insulation adds bulk and weight. Consequently, non-insulated boots are typically lighter and more flexible. This provides greater agility and can reduce fatigue over long distances, making them better suited for activities that require mobility.

Dielectric Protection

In the context of safety footwear, insulation can offer an important secondary benefit: dielectric protection. The materials used for thermal insulation often do not conduct electricity well, providing a barrier against electrical shock, particularly in wet conditions where non-insulated boots would fail.

Understanding the Trade-offs

Choosing the wrong type of boot for the conditions is a common mistake with significant consequences for both comfort and safety.

The Overheating Problem

Wearing insulated boots in moderate or warm weather is a critical error. Your feet will sweat excessively, leading to severe discomfort, an increased risk of blisters, and potentially fungal infections.

The Cold Exposure Risk

Using non-insulated boots in freezing temperatures is equally dangerous. Even if they are waterproof, they offer minimal protection against the cold, putting you at risk for cold-related injuries and making any outdoor experience miserable.

Not All Boots Are Created Equal

Remember that "waterproof" and "insulated" are separate features. You can have non-insulated waterproof boots perfect for a rainy summer day, or insulated boots that are not waterproof and are only suitable for cold, dry conditions.

Making the Right Choice for Your Goal

Select your footwear based on the most demanding conditions you expect to face.

- If your primary focus is warmth in cold, snowy, or freezing environments: Choose insulated boots, paying attention to the insulation rating (often measured in grams) for the specific temperatures you'll encounter.

- If your primary focus is performance in mild to warm weather: Opt for non-insulated boots to maximize breathability and prevent your feet from overheating.

- If your primary focus is high-exertion activity (like hiking or rucking): A non-insulated boot is almost always the better choice, even in cooler weather, as your body will be generating significant heat.

- If your primary focus is electrical hazard safety: You must select boots specifically rated for EH protection; these are often insulated but should be verified independently of their thermal properties.

Ultimately, your choice of footwear is a critical tool, and matching it correctly to the conditions is the key to both comfort and safety.

Summary Table:

| Feature | Insulated Boots | Non-Insulated Boots |

|---|---|---|

| Primary Function | Traps body heat for warmth | Maximizes breathability to release heat |

| Best For | Cold, snowy, or freezing conditions | Mild/warm weather or high-exertion activities |

| Key Benefit | Thermal protection, dielectric safety | Lightweight, flexible, prevents overheating |

| Moisture Control | Wicks internal sweat to keep feet dry | Relies on breathability and sock choice |

Need the Right Boots for Your Team or Brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of insulated and non-insulated safety and work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear, ensuring your team has the perfect blend of comfort, safety, and performance for any condition.

Contact us today to discuss your specific needs and get a customized solution!

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the three main types of toe caps? Steel, Composite, or Aluminum for Your Work Boots

- What features should workers in muddy conditions look for in work boots? | The Ultimate Guide

- Why are waterproof safety boots recommended for certain work environments? Essential Protection for Wet & Hazardous Jobs

- What role does a slip-resistant outsole play in firefighter boots? Ensuring Critical Traction and Safety

- What are the top 5 must-have features in firefighting boots? Essential Guide for Firefighter Safety

- What jobs are moc toe boots good for? Essential Footwear for Trades on Hard Surfaces

- How do manufacturers ensure a secure fit in light work boots? Discover the Engineering Behind Perfect Fit

- What specific features do Western work boots have for toe protection? A Guide to Steel & Composite Toe Caps