At its core, a slip-resistant outsole in firefighter boots provides the crucial traction and stability necessary to prevent slips and falls on the often unpredictable and hazardous surfaces firefighters encounter. This is more than just a feature; it's a fundamental element of their safety and effectiveness in life-or-death situations.

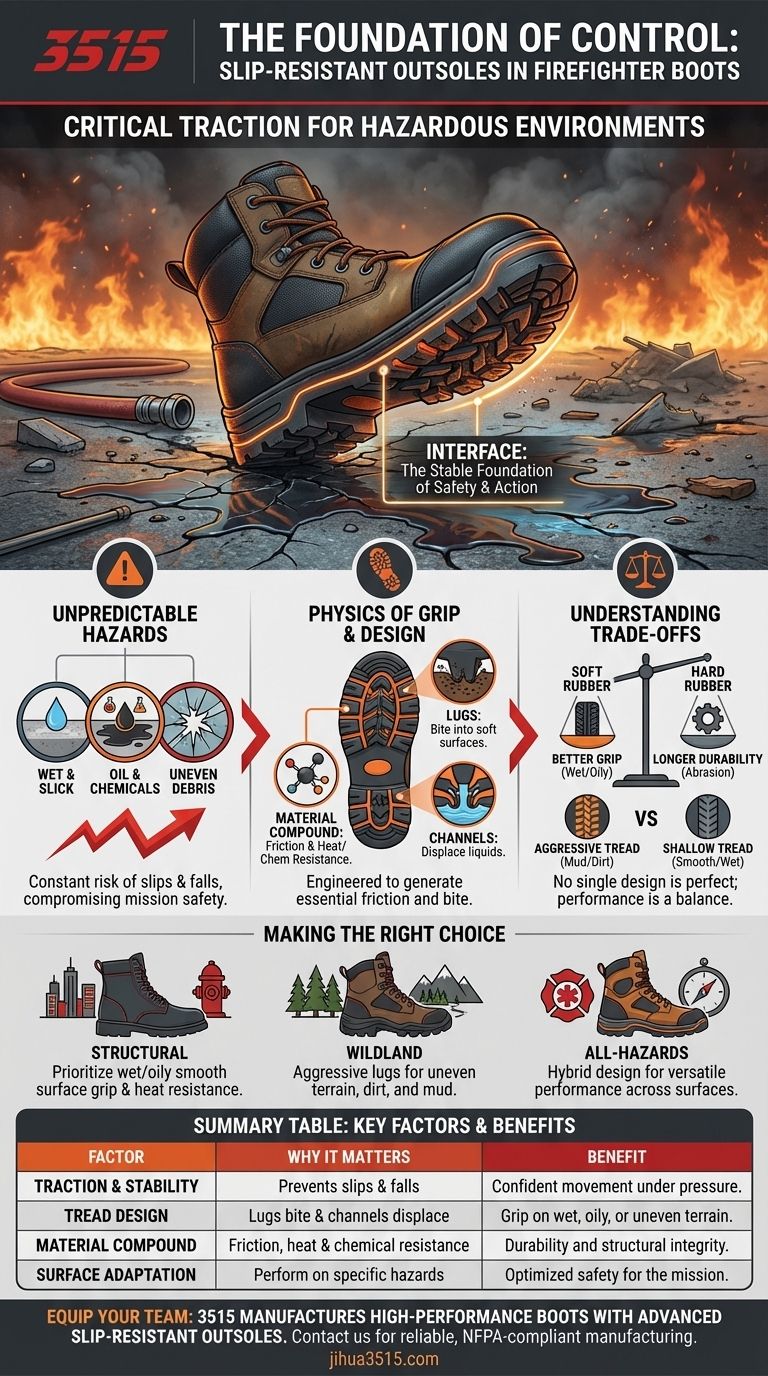

Here's the key takeaway: The outsole is the critical interface between the firefighter and their hazardous environment. It's the stable foundation upon which every action rests, from carrying heavy equipment to rescuing a victim. Its design dictates whether they stay upright, or become another casualty on the scene.

Let's break down why this is so important:

The Unforgiving Ground: Why Outsole Performance is Paramount

This is the only part of the boot that touches the ground. Its job is to firmly grip whatever surface is beneath, ensuring that the firefighter can move confidently and safely.

Firefighters face a constant barrage of unpredictable surfaces. Think about it: water from hoses turning smooth concrete into a skating rink, oil or chemical spills creating treacherous slick spots, or uneven debris like broken glass and twisted metal that offer no purchase. All of these surfaces can potentially cause a loss of balance or fall.

The physics of grip is relatively simple: it’s all about lugs (the raised parts of the tread) and the material the outsole is made of. The lugs dig into the ground, providing mechanical bite, especially on loose or uneven surfaces. The material (often a specialized rubber compound) dictates the friction between the boot and the ground. A “stickier” rubber increases friction, providing more resistance to slipping, while the design of the lugs provides further grip.

Understanding the Trade-offs

This is where things get interesting. No outsole is perfect. Design involves trade-offs.

A softer, “stickier” rubber might offer phenomenal grip, especially on wet or oily surfaces. However, it will wear down more quickly. A harder compound will last longer but might be less effective on smooth, wet surfaces where flexibility and surface area is required to displace water. This is a critical design consideration.

The tread pattern, the arrangement of the lugs, is also a trade-off. An aggressive, deep lug pattern is great for muddy terrain. But it can get clogged with debris (like mud, small stones, or even ice), reducing its grip. A shallower tread is better on smooth, wet surfaces but worse on uneven ground.

Finally, the material must be heat and chemical resistant. Firefighters face intense heat and exposure to a wide array of chemicals. The outsole cannot melt, degrade, or lose its structural integrity when exposed to these hazards. A compromised outsole means compromised slip resistance.

How to Evaluate an Outsole

So, how does a firefighter know they're getting a good outsole?

Look for certifications, like the NFPA (National Fire Protection Association) standards. These standards set minimum requirements for slip resistance, and other critical performance features.

Think about your primary work environment. A firefighter in a dense urban area, fighting structure fires, has different needs than a wildland firefighter. Those who primarily fight urban fires should prioritize outsoles effective on wet concrete or steel, while wildland firefighters need deep lugs on dirt and rock.

Making the Right Choice for Your Role

Here's a quick summary:

- For urban/structural firefighting: Prioritize outsoles with a tread design effective on wet, smooth surfaces like concrete and a compound resistant to oils and chemicals.

- For wildland or rural firefighting: Look for aggressive, deep lugs designed for maximum grip on uneven terrain, dirt, and mud.

- For all-hazards response: Seek a balanced, hybrid outsole design that provides reliable performance across a wide range of surfaces without excelling at one extreme.

Ultimately, the outsole is the foundation of your safety and ability to perform your duties. A well-designed, appropriate outsole can be the difference between a controlled situation and a life-altering accident. At its core, a slip-resistant outsole is the critical foundation of a firefighter's safety and mobility. It is engineered to provide essential traction and stability on the hazardous and unpredictable surfaces encountered during an emergency, directly preventing the slips and falls that can lead to serious injury or compromise a mission.

The function of a slip-resistant outsole goes far beyond simple grip. It is a firefighter's only point of contact with an unstable environment, acting as the primary tool for maintaining balance and control while performing life-saving tasks under extreme pressure.

The Foundation of Control: Why Outsole Performance is Paramount

A firefighter's effectiveness is directly tied to their ability to move with confidence. The outsole is the single most important component in enabling that movement, translating the wearer's power and skill into controlled action on the ground.

The Core Function: Traction and Stability

The outsole is the part of the boot that meets the ground. Its primary job is to generate friction, providing the grip necessary to push off, stop suddenly, carry heavy loads, and remain upright on compromised surfaces.

Without reliable traction, every other safety feature of the boot becomes less effective.

Navigating Unpredictable Environments

Firefighters rarely operate on clean, dry, or level ground. They face a chaotic mix of surfaces, including water from fire hoses, spilled oils or chemicals, broken glass, and uneven debris from structural collapse.

A properly designed slip-resistant outsole is tested to maintain its grip across this wide spectrum of wet and dry hazards, ensuring a stable footing when it matters most.

The Physics of Grip: Material and Design

Slip resistance is not an accident; it is a result of deliberate engineering. Two key factors determine an outsole's performance.

First is the material, typically a specialized rubber compound formulated for a high coefficient of friction. Second is the tread design, which includes the depth and pattern of the lugs that bite into the surface and channel away liquids.

Understanding the Trade-offs

No single outsole design is perfect for every possible scenario. Manufacturers must balance competing demands, and understanding these compromises is key to selecting the right boot.

Grip vs. Durability

Softer rubber compounds often provide superior grip, especially on smooth, wet surfaces, because they can conform more effectively to microscopic imperfections. However, these materials may wear down faster.

Conversely, harder compounds offer excellent longevity and abrasion resistance but can sometimes sacrifice a degree of traction.

Tread Pattern vs. Surface Type

An aggressive, deep-lugged outsole is ideal for digging into soft terrain like mud or loose dirt. However, on a flat, smooth surface, those same deep channels can reduce the total surface area in contact with the ground, potentially lessening grip.

Furthermore, aggressive treads can become clogged with mud or debris, which severely compromises their effectiveness until cleaned.

Resistance to Heat and Chemicals

An outsole's material must do more than just grip. It must also withstand exposure to extreme heat without melting and resist degradation from contact with chemicals and oils.

A material that breaks down under these conditions will lose its structural integrity and its slip-resistant properties, leading to catastrophic failure.

Making the Right Choice for Your Role

Evaluating an outsole requires you to match its specific design characteristics to the demands of your most common operational environment.

- If your primary focus is structural firefighting: Prioritize an outsole with a tread pattern designed for wet and oily flat surfaces, like concrete or tile, and certified for high heat resistance.

- If your primary focus is wildland or rural response: Look for an aggressive outsole with deep, self-cleaning lugs that provide maximum traction on uneven ground, hillsides, and loose soil.

- If your primary focus is all-hazards technical rescue: Seek a versatile, hybrid outsole that offers a balance of reliable grip on both natural and man-made surfaces.

Ultimately, choosing the right boot means treating the outsole as the most critical piece of equipment for ensuring your footing and operational safety.

Summary Table:

| Key Factor | Why It Matters for Firefighters |

|---|---|

| Traction & Stability | Prevents slips and falls, enabling confident movement under pressure with heavy equipment. |

| Tread Design | Lugs and channels bite into surfaces and displace liquids for grip on wet, oily, or uneven terrain. |

| Material Compound | Specialized rubber provides high friction and resists heat, chemicals, and wear for durability. |

| Surface Adaptation | Designed to perform on a wide range of hazards, from smooth concrete to muddy debris. |

Equip Your Team with Boots Built for the Mission

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized boots, including those engineered with advanced slip-resistant outsoles for firefighting and other demanding professions.

We provide the durability, certification compliance (like NFPA), and specialized traction your customers rely on. Let's discuss how we can support your business with reliable, high-volume manufacturing.

Contact our team today to request a quote or discuss your specific requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the different materials used to make work boots? Choose the Right Boot for Your Job

- How long should you wait before wearing boots after waterproofing? Ensure Maximum Durability

- What are the key characteristics of cowboy boots for farm work? Durable, Stable & Protective Footwear

- What are the benefits of easy-to-clean farming and gardening boots? Boost Efficiency, Safety & Durability

- What should you do when your work boots no longer serve their purpose? Don't Gamble with Your Safety

- Why is it important to replace safety boots over time? Avoid Hidden Hazards and Ensure Protection

- What are some ways to enhance an outfit with moc toe boots? Master Rugged, Smart-Casual & Modern Styles

- What protective features do high-performance work boots offer? Expert Guide for Heavy Handling & Climbing Safety