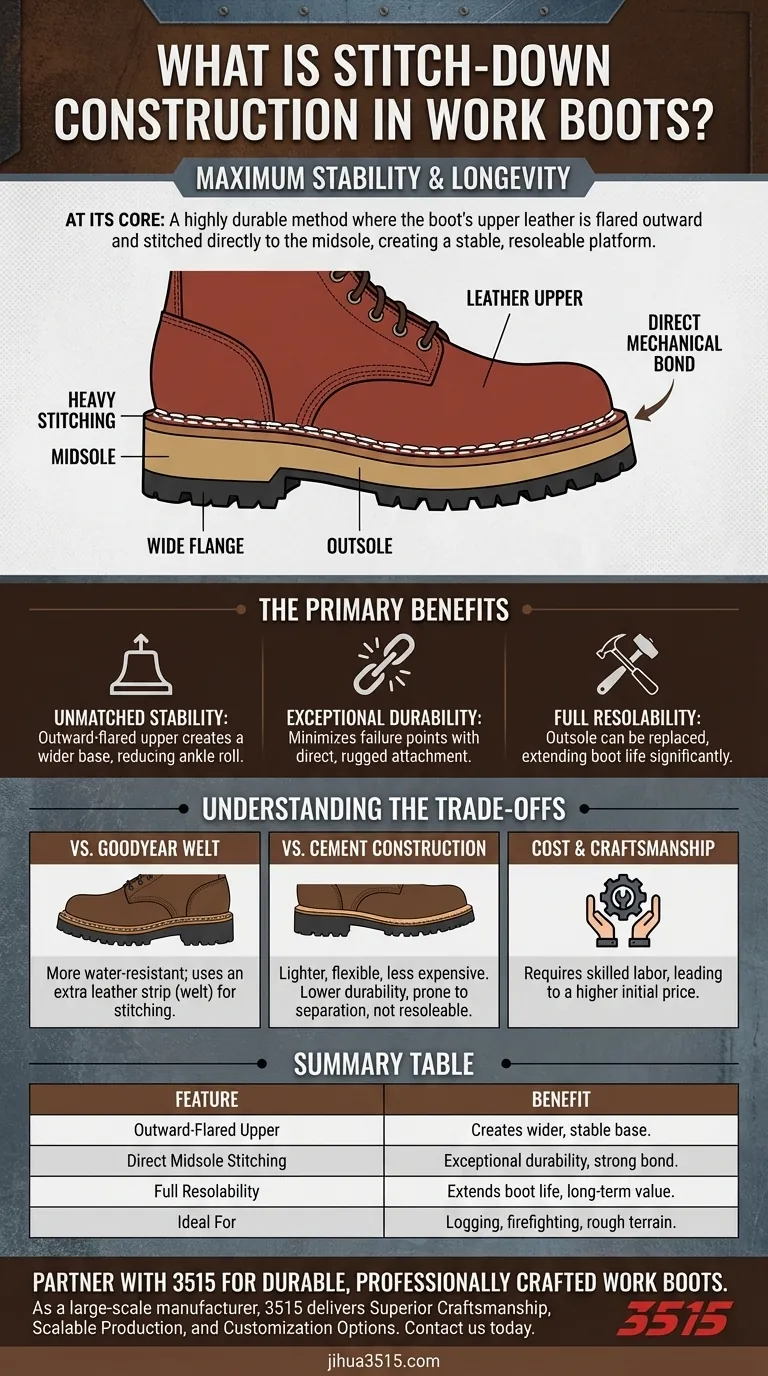

At its core, stitch-down construction is a highly durable method where the boot's upper leather is flared outward and stitched directly to the midsole. This process, performed by skilled craftspeople, creates an exceptionally stable and robust platform that can be resoled multiple times, significantly extending the life of the boot.

The critical takeaway is that stitch-down construction prioritizes maximum stability and longevity. It is a premium, labor-intensive method chosen for the most demanding work environments where a solid footing is non-negotiable.

How Stitch-Down Construction Works

The stitch-down method is defined by its unique approach to uniting the boot's upper with its sole, creating a distinct and highly functional structure.

The Outward-Flared Upper

The defining characteristic of this method is how the leather upper is handled. Instead of being tucked under, the leather is splayed or flared outward, creating a wide flange around the base of the boot.

Direct Midsole and Outsole Attachment

This flared leather is then stitched directly through to the midsole using heavy, durable thread. This creates an incredibly strong mechanical bond. Finally, the outsole is cemented and often stitched to this secure midsole platform.

The Primary Benefits of Stitch-Down Boots

Choosing a stitch-down boot is an investment in specific performance characteristics. The construction method delivers tangible advantages in demanding conditions.

Unmatched Stability

The outward-flared upper creates a wider, more stable base than most other construction types. This provides a very planted and secure feel, reducing the risk of ankle roll on uneven terrain.

Exceptional Durability

By stitching the upper directly to the midsole, the construction minimizes the number of potential failure points. This direct attachment is famously rugged and resistant to separating under high stress.

Full Resolability

Like other premium construction methods, stitch-down boots are fully resoleable. When the outsole wears down, a cobbler can remove it and attach a new one, giving the boots a second or even third life.

Understanding the Trade-offs

No construction method is superior in all aspects. The strengths of stitch-down construction come with specific trade-offs compared to other common methods.

Stitch-Down vs. Goodyear Welt

These are the two titans of durable boot construction. In a Goodyear welt, the upper is stitched to a leather strip (the welt), which is then stitched to the sole. In stitch-down, the upper is stitched directly to the midsole.

Goodyear welting is often considered more water-resistant due to the extra layers, while stitch-down provides that wider, more stable platform. Both are highly durable and resoleable.

Stitch-Down vs. Cement Construction

Cement construction is a common method where the sole is simply glued to the upper. This results in a lighter, more flexible, and less expensive boot.

The trade-off is a significant loss in durability. Cemented boots are prone to sole separation under hard use and are typically not resoleable.

Cost and Craftsmanship

Stitch-down construction requires significant skill and time to execute properly. This specialized labor directly translates to a higher initial purchase price compared to more automated methods.

Making the Right Choice for Your Work

Choosing the right construction is about matching the boot's design to your specific needs and priorities.

- If your primary focus is maximum stability and long-term durability: A stitch-down boot is an elite choice, ideal for logging, firefighting, or work on rough terrain.

- If your primary focus is a balance of durability, water resistance, and classic style: The industry-standard Goodyear welt is an excellent and widely available option.

- If your primary focus is lightweight comfort and affordability for light-duty tasks: Cement construction offers the most value and flexibility.

Understanding the construction of your boot is the first step toward investing in a true piece of professional equipment.

Summary Table:

| Feature | Benefit |

|---|---|

| Outward-Flared Upper | Creates a wider, more stable base for superior footing. |

| Direct Midsole Stitching | Provides exceptional durability and a strong mechanical bond. |

| Full Resolability | Extends boot life significantly, offering long-term value. |

| Ideal For | Demanding work like logging, firefighting, and rough terrain. |

Need Durable, Professionally Crafted Work Boots? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, including premium stitch-down construction models built for the toughest jobs.

We deliver:

- Superior Craftsmanship: Boots designed for maximum stability and longevity.

- Scalable Production: Reliable supply to meet your business needs.

- Customization Options: Tailor styles and specifications for your market.

Contact us today to discuss how our manufacturing expertise can provide the durable footwear your customers rely on.

Get a Quote & Discuss Your Needs

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What maintenance tips should be followed for farm boots? Extend Their Lifespan & Protect Your Feet

- What are some ASTM standards for work boots? A Guide to Certified Footwear Safety

- Why is slip resistance important in oilfield work boots? Essential Safety & Material Guide

- What factors should be considered when choosing between PVC, neoprene, and rubber work boots?

- Why is comfort important in work boots? The Critical Link Between Comfort and Safety

- What materials contribute to the durability of Western work boots? Uncover the Secrets to Long-Lasting Footwear

- How did moc toe boots originate? A Legacy of Workwear Durability and Style

- What are the main advantages of pull-on work boots? Unlock Speed, Safety & Durability