The key ASTM standards for work boots are ASTM F2413, which covers requirements for safety toes, metatarsal guards, and puncture resistance, and ASTM F3445, which specifies performance for slip resistance. Other critical standards include ASTM F2892 for non-safety toe electrical hazard footwear and ASTM F1671 for resistance to blood-borne pathogens. These codes are a universal language for workplace safety.

The array of ASTM standards is not a checklist to be memorized, but a system for matching specific footwear capabilities to the known hazards of your work environment. Understanding the core standards transforms a simple purchase into a calculated investment in personal safety.

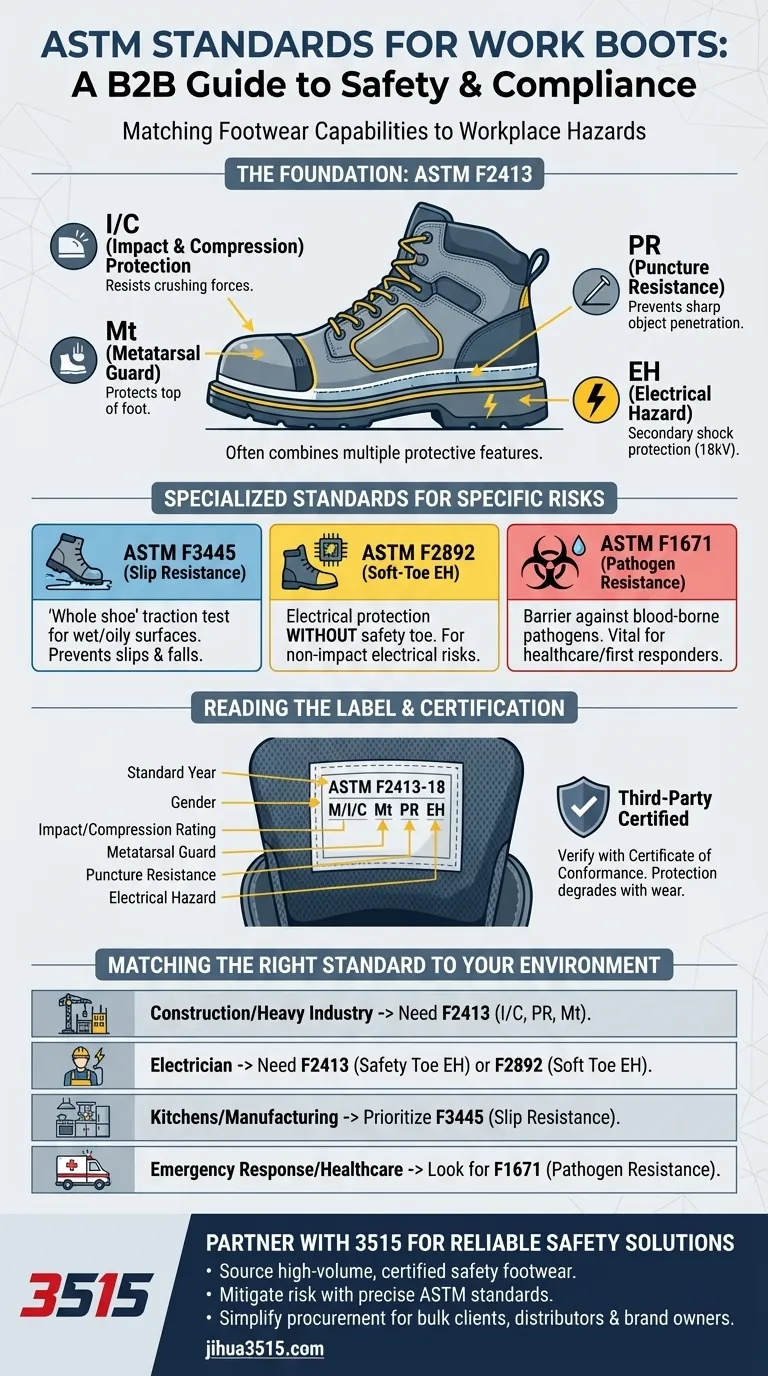

The Foundation of Footwear Safety: ASTM F2413

The most common standard you will encounter is ASTM F2413-18. This is the standard specification for performance requirements for protective (safety) toe cap footwear. It acts as the foundational standard, often incorporating several different protective features into one boot.

Impact & Compression (I/C) Protection

This is the classic "steel toe" requirement, though the protective cap can also be made of composite materials or aluminum. The I/C rating indicates the boot's toe box has been tested to protect against specific levels of impact and crushing forces.

A boot label will specify the rating, such as I/75 C/75, which is the highest level of protection.

Metatarsal (Mt) Guard

For workplaces with a high risk of objects falling or rolling onto the top of the foot, a metatarsal guard is essential. This feature, designated as Mt, adds protection over the instep area, which is not covered by the safety toe alone.

Puncture Resistance (PR)

If you work around sharp objects like nails, screws, or scrap metal, a puncture-resistant boot is critical. These boots have a plate integrated into the midsole to prevent sharp objects from piercing the sole of the boot and injuring your foot.

Electrical Hazard (EH) Resistance

EH-rated footwear is designed to provide a secondary source of protection from live electrical circuits. These boots are manufactured with non-conductive, shock-resistant soles and heels, capable of withstanding the application of 18,000 volts at 60 Hz for one minute with no current flow.

Specialized Standards for Specific Risks

While ASTM F2413 covers the most common industrial hazards, other standards address unique environmental risks. These are often just as critical for ensuring comprehensive safety.

Slip Resistance: ASTM F3445-21

Slips, trips, and falls are among the most common workplace injuries. ASTM F3445-21 is the standard test method for measuring the slip resistance of footwear on wet, oily, or otherwise slick surfaces.

Unlike older standards, this one provides a more realistic and rigorous "whole shoe" test. A boot that passes this standard offers proven traction performance.

Soft-Toe Electrical Protection: ASTM F2892-18

This standard applies to footwear that offers electrical hazard protection but does not have a protective safety toe. It is intended for roles where electrical risk is the primary concern, but the danger of impact or compression is minimal.

Pathogen Resistance: ASTM F1671-13

For first responders, healthcare workers, or anyone potentially exposed to bodily fluids, this standard is vital. It specifies a test method for measuring the resistance of materials to penetration by blood-borne pathogens, ensuring the boot's materials act as a reliable barrier.

Understanding the Labels and Limitations

A standard is only effective if it is properly certified and you know how to verify it. Understanding the label and the trade-offs is crucial.

Reading the Boot's Label

Certified footwear will have a label stitched into the interior, often on or under the tongue. This label provides a clear, formatted line of text explaining exactly which ASTM standards the boot meets.

A typical label might read: ASTM F2413-18 M/I/C Mt PR EH. This single line tells you the boot meets the 2018 standard for Men (M), with top-rated Impact and Compression resistance, a Metatarsal guard, Puncture Resistance, and Electrical Hazard protection.

Certification is Non-Negotiable

To be officially compliant, footwear must be tested by an independent, third-party laboratory. The manufacturer should be able to provide a Certificate of Conformance proving that their product meets the specific ASTM standards claimed on the label.

Protection Has Its Limits

No work boot is indestructible. An EH rating degrades if the sole is punctured or worn down, and a safety toe can only withstand a single major impact. Always inspect your footwear for damage and replace it when its protective features are compromised.

Making the Right Choice for Your Environment

Choosing the correct footwear is a matter of assessing your specific workplace hazards and matching them to the corresponding ASTM standard.

- If your primary focus is construction or heavy industry: You need a boot certified to ASTM F2413 with I/C, PR, and potentially Mt ratings.

- If your primary focus is working as an electrician: An EH-rated boot under ASTM F2413 (with a safety toe) or ASTM F2892 (soft toe) is mandatory.

- If your primary focus is kitchens, hospitals, or manufacturing: Prioritize a boot that meets ASTM F3445-21 for superior slip resistance.

- If your primary focus is emergency response or healthcare: Look for boots tested against ASTM F1671-13 to protect against blood-borne pathogens.

By learning to read the language of ASTM standards, you can confidently select footwear that provides precisely the protection you need.

Summary Table:

| ASTM Standard | Key Protection | Common Use Cases |

|---|---|---|

| ASTM F2413 | Impact/Compression (I/C), Metatarsal (Mt), Puncture (PR), Electrical Hazard (EH) | Construction, Heavy Industry, Warehousing |

| ASTM F3445 | Slip Resistance on Wet/Oily Surfaces | Kitchens, Healthcare, Manufacturing |

| ASTM F2892 | Electrical Hazard (EH) without Safety Toe | Electrical Work, Low-Impact Environments |

| ASTM F1671 | Resistance to Blood-Borne Pathogens | Emergency Response, Healthcare, Laboratories |

Ensure Your Team Has the Right Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified work boots and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots, ensuring your workforce is equipped for any hazard.

Partner with us to:

- Source Reliably: Get consistent, high-volume production of certified safety footwear.

- Mitigate Risk: Equip your teams with boots that meet precise ASTM standards for their specific work environments.

- Simplify Procurement: Work with a single manufacturer capable of fulfilling all your protective footwear needs.

Ready to enhance your safety supply chain? Contact our team today to discuss your requirements and receive a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the properties of rubber as an upper material for work boots? A Guide to Waterproof Durability vs. Comfort

- What are the common materials used for the upper part of work boots? Choose the Right Protection

- What are the disadvantages of lace-up work boots? Weighing Convenience Against Support

- Can motorcycle boots be worn for everyday use? Finding the Perfect Balance for Daily Wear

- In what scenarios is PU most suitable for work boots? Boost Comfort & Reduce Fatigue for Light-Duty Work

- What are the five most important components of boot fitting? A Guide to Perfect Fit & Performance

- What should be considered when purchasing work boots? A Guide to Choosing the Right Protection

- What makes Western work boots durable and long-lasting? The Trifecta of Quality Materials, Repairable Construction & Design