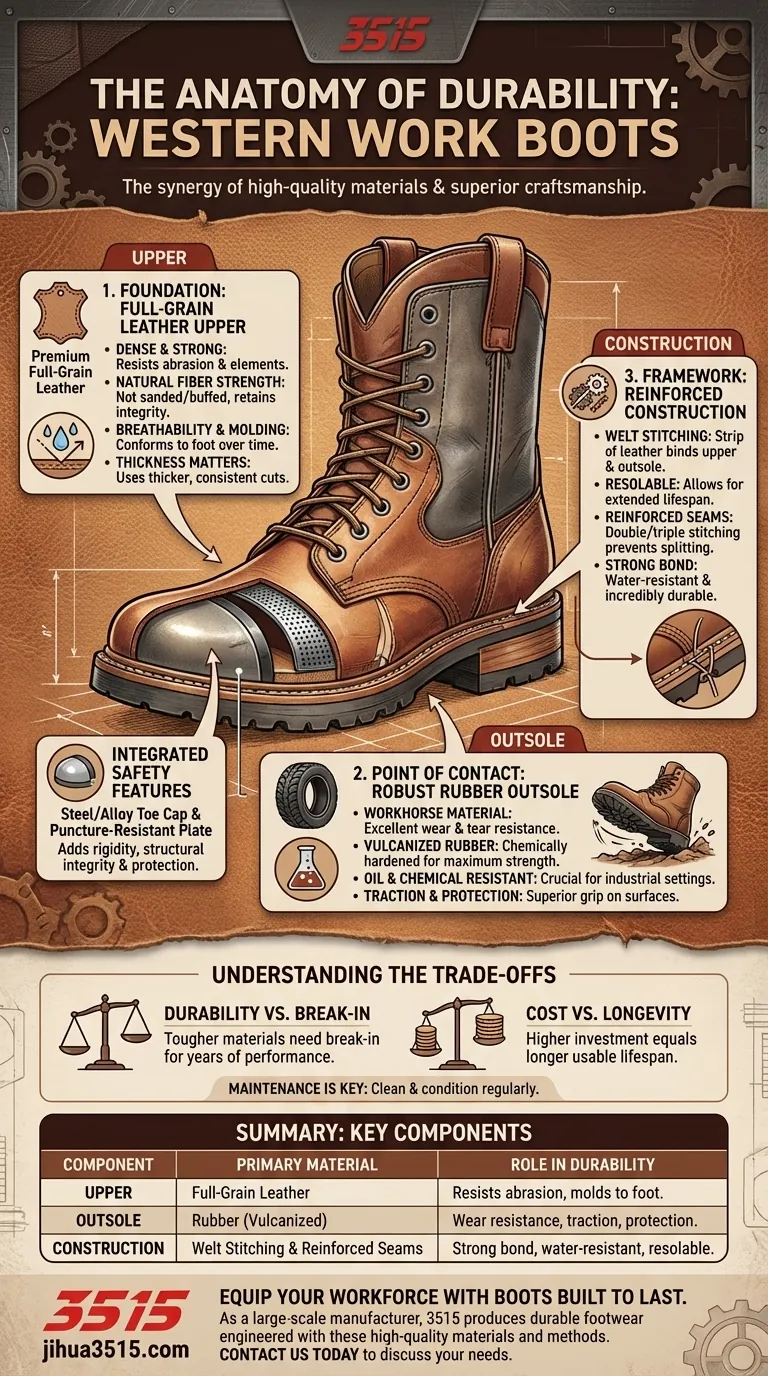

At its core, the durability of a Western work boot comes from a combination of three key elements: high-quality full-grain leather for the upper, robust rubber for the outsole, and reinforced construction methods like welt stitching that bind them together. These components are specifically chosen to withstand the abrasion, stress, and hazards of demanding work environments.

True durability isn't found in a single material, but in the synergy between the right materials and the quality of craftsmanship. A boot's ability to last is a direct result of how its leather, sole, and stitching work together as a complete system.

The Foundation of Durability: The Leather Upper

The main body of the boot, known as the upper, is the first line of defense against the elements and workplace wear. Its material composition is the primary factor in the boot's overall lifespan.

Full-Grain Leather: The Gold Standard

Full-grain leather is the most critical material for a durable Western work boot. It is taken from the top layer of the hide and contains all the natural grain, making it incredibly dense and strong.

Unlike lesser grades of leather, it is not sanded or buffed, so it retains its natural fiber strength and breathability. This material is prized for its ability to resist moisture and abrasion while molding to the wearer's foot over time.

The Role of Material Thickness and Quality

Not all full-grain leather is created equal. The thickness of the hide and the skill of the artisans who select and cut it play a significant role.

Premium boots use thicker, more consistent cuts of leather, ensuring there are no weak points. This robust construction contributes directly to the boot's longevity and its ability to handle hard use.

The Point of Contact: The Outsole

The outsole is what meets the ground, and its material dictates the boot's traction, wear resistance, and protection from hazards.

Rubber: The Workhorse Material

Rubber is the most common and durable material for a work boot outsole. It offers excellent resistance to wear, tear, and abrasion.

Specialized rubber compounds are also resistant to oil and chemicals, which is crucial in many industrial settings. For maximum strength, some boots use vulcanized rubber, which has been chemically hardened to further increase its durability.

Other Sole Materials

While less common in heavy-duty Western work boots, materials like PVC and neoprene are sometimes used. These are strong but are generally more susceptible to cuts and tears than high-quality rubber, making them better suited for less demanding conditions.

The Framework: Construction and Reinforcement

The world's best materials are useless if they aren't held together properly. The construction method is the skeleton that gives the boot its strength.

Reinforced Stitching: The Unsung Hero

Look closely at the seams of a quality boot. You will find thick, robust thread and often double or triple rows of stitching in high-stress areas.

This reinforced stitching prevents the boot from splitting or separating under the constant flexing and strain of physical labor.

Welt Construction: The Mark of Quality

Many high-end work boots use a stitch-down welt. This is a method where a strip of leather (the welt) is stitched to both the upper and the outsole.

This creates an incredibly strong and water-resistant bond. Crucially, it also allows the boot to be resoled by a cobbler, dramatically extending its usable lifespan far beyond that of a boot with a glued-on sole.

Integrated Safety Features

For many, durability is synonymous with safety. Features like steel or alloy toe caps and puncture-resistant plates are integrated into the boot's structure.

These components not only protect the wearer but also add rigidity and structural integrity to the front of the boot, helping it hold its shape and resist crushing forces.

Understanding the Trade-offs

Choosing the right boot involves balancing competing factors. The most durable option is not always the perfect choice for every situation.

Durability vs. Break-in Period

The toughest materials, like thick full-grain leather and rigid rubber soles, require a break-in period. They may feel stiff at first, but this initial investment in comfort pays off with years of reliable performance.

Cost vs. Longevity

There is a direct correlation between price and the quality of materials and construction. A cheaper boot may use lower-grade leather and glued soles that wear out quickly. A more expensive, welted boot made of full-grain leather is a long-term investment that often costs less per year of use.

Maintenance is Non-Negotiable

The best materials in the world will fail without proper care. Leather needs to be cleaned and conditioned regularly to prevent it from drying out, cracking, and losing its water resistance. A durable boot is one that is well-maintained.

Making the Right Choice for Your Work

Your specific needs should guide your decision. Use the material and construction knowledge to select a boot that aligns with your daily demands.

- If your primary focus is maximum longevity in harsh environments: Seek out a boot made from thick, full-grain leather with a Goodyear welt and a solid vulcanized rubber outsole.

- If your primary focus is safety on a construction site: Prioritize boots with certified steel or alloy toe caps and puncture-resistant plates built into a durable leather and rubber frame.

- If your primary focus is all-day comfort on hard surfaces: Ensure the boot's durable construction is paired with excellent cushioning, arch support, and a proper fit from the start.

Ultimately, investing in boots built with superior materials and craftsmanship is an investment in your own comfort, safety, and long-term value.

Summary Table:

| Key Component | Primary Material | Role in Durability |

|---|---|---|

| Upper | Full-Grain Leather | Resists abrasion, moisture, and molds to the foot. |

| Outsole | Rubber (often Vulcanized) | Provides wear resistance, traction, and oil/chemical protection. |

| Construction | Welt Stitching & Reinforced Seams | Creates a strong, water-resistant bond and allows for resoling. |

Ready to equip your workforce with boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, engineered with the high-quality materials and construction methods detailed above to ensure superior performance, safety, and longevity.

Contact us today to discuss your specific needs and discover how we can deliver exceptional value and durability to your customers.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What industries is this boot designed for? Ideal for Oil & Gas and Chemical Manufacturing

- How can you ensure consistent comfort in work boots? Focus on Fit, Materials & Ergonomics

- How should wildfire boots be maintained for optimal performance? A Guide to Longevity and Safety

- Why are moisture-wicking and breathable linings necessary for Work Boots? Optimize Heat Management and Foot Health

- What are pull-on work boots? Unlock Speed vs. Support for Your Workforce

- Why is breathability important in fire boots? The Critical Link to Safety and Performance

- What are the safety considerations for construction work boots? Essential Protection for Every Job Site

- Why is proper fit important in work boots? Ensure Safety, Comfort & Long-Term Health