The most sustainable material for Wellington boots is natural rubber. Sourced from the latex of rubber trees, it is a completely renewable and biodegradable resource that provides the durability and waterproof performance expected from this type of footwear, standing in stark contrast to synthetic plastics derived from fossil fuels.

The key to a sustainable choice is not just the primary material but its entire lifecycle. Prioritizing renewable and biodegradable options like natural rubber over non-degradable synthetics like PVC is the most effective approach.

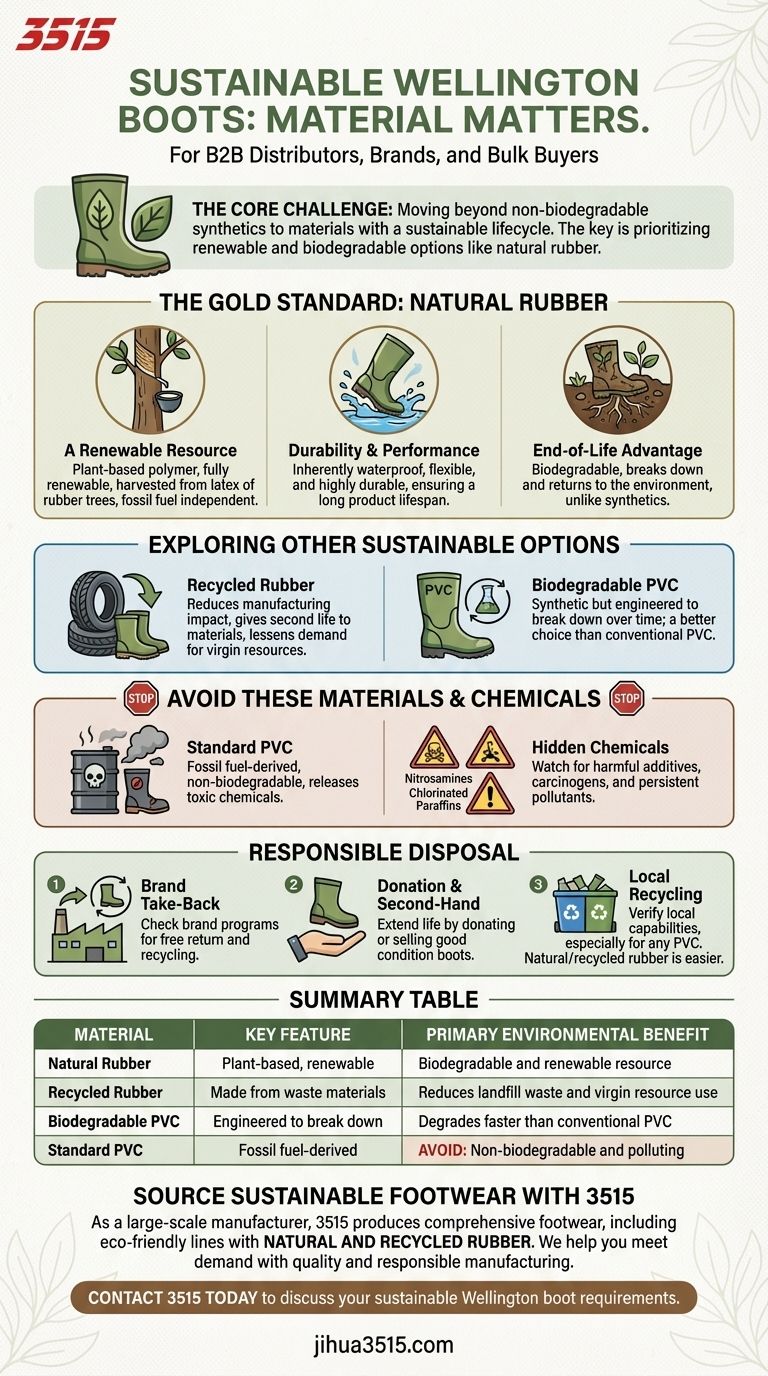

The Gold Standard: Natural Rubber

Natural rubber is widely considered the best-in-class material for sustainable Wellington boots due to its unique combination of performance and environmental benefits.

A Renewable Resource

Unlike synthetic plastics, natural rubber is a plant-based polymer. It is harvested as latex from rubber trees, making it a fully renewable resource that does not depend on fossil fuels for its creation.

Durability and Performance

Functionally, natural rubber is an ideal material for boots. It is inherently waterproof, flexible, and highly durable, ensuring a long product lifespan, which is a key component of sustainability.

End-of-Life Advantage

Crucially, natural rubber is biodegradable. At the end of its life, it can break down and return to the environment, unlike synthetic materials that persist for centuries.

Exploring Other Sustainable Options

While natural rubber leads the pack, other materials offer significant environmental improvements over conventional choices.

Recycled Rubber

Using recycled rubber reduces the environmental impact of manufacturing. This approach gives a second life to materials that would otherwise end up in a landfill and lessens the demand for virgin resources.

Biodegradable PVC

Some manufacturers offer biodegradable PVC as an alternative. While still a synthetic plastic, it is specifically engineered to break down over time when exposed to the elements, making it a better choice than its conventional counterpart.

Understanding the Trade-offs and Materials to Avoid

Making an informed choice requires knowing what materials to steer clear of and why they are problematic.

The Problem with Standard PVC

Conventional Polyvinyl Chloride (PVC) is a common material for cheaper boots but poses significant environmental issues. It is derived from fossil fuels, does not biodegrade, and can release toxic chemicals into the environment as it slowly breaks apart.

Hidden Chemicals of Concern

Be wary of harmful additives sometimes used in production. Nitrosamines are carcinogenic compounds, while chlorinated paraffins are persistent environmental pollutants that can accumulate in the food chain.

A Note on Responsible Disposal

The sustainability of your boots also depends on how you handle them at the end of their useful life.

Brand Take-Back Programs

Before discarding old boots, check the brand's website. Many sustainable companies offer free return and recycling schemes to ensure their products are handled responsibly.

Donation and Second-Hand Use

If the boots are still in good, usable condition, the best option is to donate or sell them. Extending the product's life is a highly effective form of sustainability.

Local Recycling Considerations

If you must recycle the boots yourself, the material matters. Natural and recycled rubber are more easily processed. For any type of PVC, you must check with your local recycling center to see if they can accept it.

Making the Right Choice for Your Goal

Your final decision should align with your primary environmental priority.

- If your primary focus is maximum sustainability: Choose boots made from 100% natural rubber, as it is both renewable and biodegradable.

- If your primary focus is reducing manufacturing waste: Look for options made from a high percentage of recycled rubber to support a circular economy.

- If you are choosing between synthetic options: Opt for biodegradable PVC over standard PVC to ensure the material can break down at the end of its life.

By understanding the material source and its lifecycle, you can confidently select footwear that is not only functional but also aligned with your environmental values.

Summary Table:

| Material | Key Feature | Primary Environmental Benefit |

|---|---|---|

| Natural Rubber | Plant-based, renewable | Biodegradable and renewable resource |

| Recycled Rubber | Made from waste materials | Reduces landfill waste and virgin resource use |

| Biodegradable PVC | Engineered to break down | Degrades faster than conventional PVC |

| Standard PVC | Fossil fuel-derived | Avoid: Non-biodegradable and polluting |

Source Your Sustainable Footwear with 3515, Your Trusted Manufacturing Partner

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including eco-friendly lines featuring natural and recycled rubber. We help you meet the growing demand for sustainable products with quality, durability, and responsible manufacturing.

Contact 3515 today to discuss your sustainable Wellington boot requirements and leverage our expertise for your brand.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What is the cultural impact of Wellington boots? From Battlefields to Fashion Runways

- What makes a particular brand's wellies suitable for babies and toddlers? Prioritize Healthy Foot Development

- What are the pros and cons of wellington boots? A Guide to Waterproof Footwear Choices

- What should be considered about the sole unit when choosing wellington boots? Find the Perfect Grip & Comfort

- Why are wellies a good choice for gardening? Find Your Perfect Fit for Muddy Tasks

- What are wellington boots commonly known as and what activities are they associated with? Discover the Versatile 'Wellie'

- How can you eliminate odors in rubber boots? Banish Smells with Simple, Effective Methods

- What are the advantages of natural rubber in half-boots? Superior Comfort, Durability & Eco-Friendliness