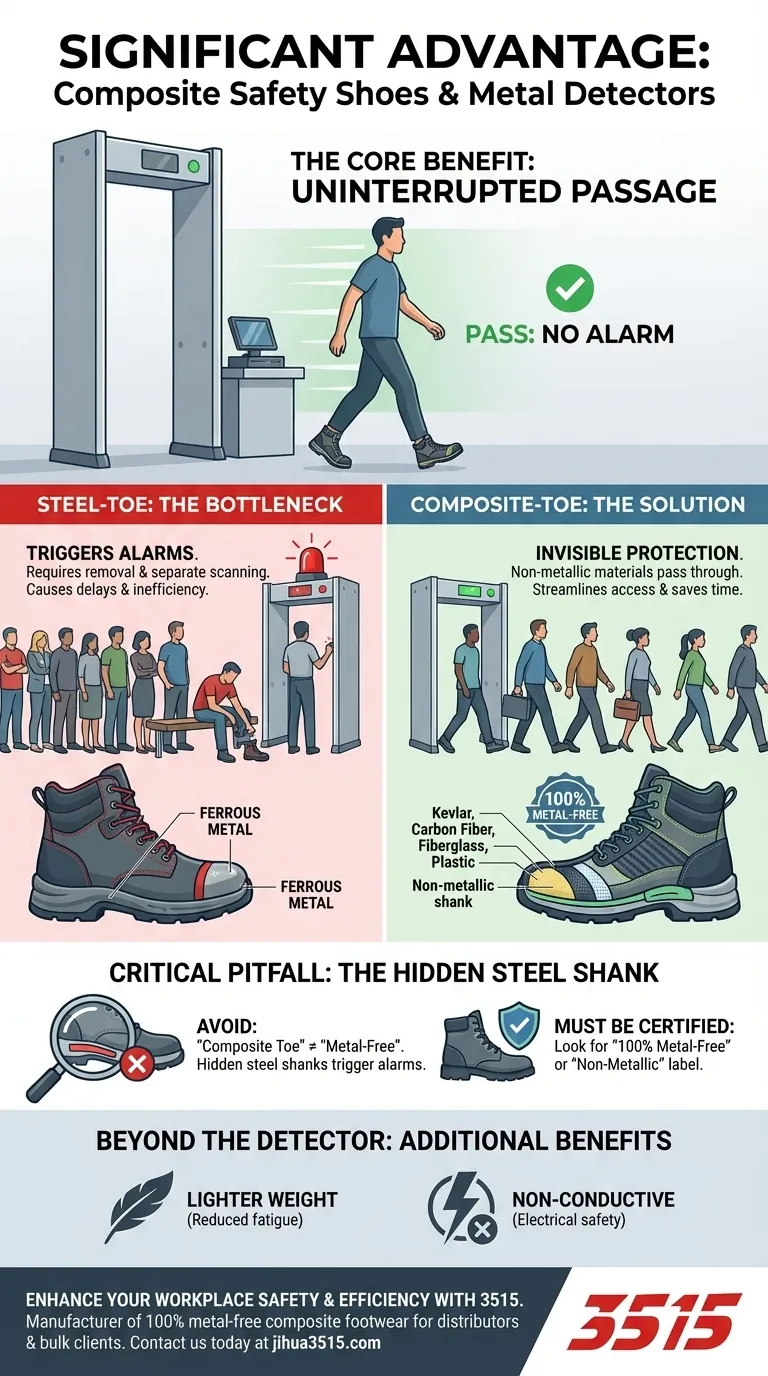

The single greatest advantage of composite safety shoes in workplaces with metal detectors is their ability to pass through security screening without triggering an alarm. Unlike their steel-toed counterparts, which necessitate removal and separate scanning, composite-toe footwear allows for uninterrupted passage, significantly improving operational efficiency and personal convenience.

The core benefit of composite footwear is its non-metallic nature, which streamlines movement through security checkpoints. However, to fully realize this advantage, you must ensure the entire shoe is certified as "100% metal-free," not just the toe cap.

The Core Problem: Steel vs. Security Checkpoints

How Steel Toes Trigger Alarms

Steel-toe boots contain a cap of ferrous metal over the toe box. Metal detectors work by generating a magnetic field, and when a conductive metal like steel passes through, it disrupts this field and triggers an alarm.

This is a fundamental physical property, meaning a standard steel-toe boot will reliably set off a properly calibrated metal detector every time.

The Operational Inefficiency

For an individual, removing boots at a security checkpoint is a minor hassle. For an organization with hundreds of employees entering and exiting a secure facility daily, this process creates significant bottlenecks.

The repeated act of stopping, removing footwear, and waiting for manual checks consumes valuable time and complicates workflow logistics.

Composite Toes as the Solution

"Invisible" Protection

Composite safety toes are crafted from non-metallic materials such as Kevlar, carbon fiber, fiberglass, or plastic. These materials provide certified impact and compression protection without possessing the magnetic properties of steel.

Because they do not conduct electricity or interact with magnetic fields, they are effectively "invisible" to metal detectors.

Streamlining Workplace Access

The practical benefit is seamless entry and exit. Employees can walk directly through security checkpoints without needing to remove their footwear, saving time and eliminating a point of friction in their daily routine.

This is especially critical in high-security environments like airports, power plants, or sensitive government facilities where screening is mandatory.

Beyond the Metal Detector

While their primary benefit in this context is being metal-free, composite materials offer other advantages. They are typically lighter than steel, which can reduce foot fatigue over a long shift.

They are also non-conductive, offering superior protection against electrical hazards compared to steel, which can transfer electricity.

Common Pitfalls to Avoid

The Hidden Steel Shank

A critical mistake is assuming a "composite toe" means a "metal-free boot." Many safety boots, including some with composite toes, contain a steel shank in the midsole for arch support and puncture resistance.

This hidden steel component will trigger a metal detector just as easily as a steel toe, negating the primary advantage.

Verifying "100% Metal-Free"

To avoid this issue, you must look for footwear explicitly labeled as "100% metal-free" or "non-metallic."

This certification ensures that not only the toe cap but also all other components—such as the eyelets, hardware, and shank—are made from non-metallic materials.

Making the Right Choice for Your Environment

Choosing the correct footwear requires aligning its features with your primary operational needs.

- If your primary focus is unimpeded passage through metal detectors: You must select a boot that is explicitly certified as 100% metal-free.

- If your primary focus is protection from electrical hazards: The non-conductive properties of a fully composite boot make it the superior choice.

- If your primary focus is long-shift comfort: The lighter weight of composite footwear can significantly reduce fatigue compared to heavier steel-toe options.

Ultimately, selecting truly non-metallic footwear is a strategic choice to enhance both workplace safety and operational efficiency.

Summary Table:

| Feature | Steel-Toe Boots | Composite-Toe Boots |

|---|---|---|

| Metal Detector Alarms | Triggers alarms, requires removal | Passes through without triggering |

| Material Composition | Ferrous metal (steel) | Non-metallic (Kevlar, carbon fiber, plastic) |

| Electrical Conductivity | Conductive, risk of electrical hazards | Non-conductive, safer near electricity |

| Weight | Heavier, can cause fatigue | Lighter, reduces foot fatigue |

| Key Consideration | Not suitable for high-security zones | Must be certified '100% metal-free' (including shank) |

Enhance Your Workplace Safety and Efficiency with 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of 100% metal-free composite safety footwear designed specifically for environments with metal detectors. Our boots ensure your team passes through security checkpoints seamlessly, saving time and boosting productivity.

Our Value to You:

- For Distributors & Brand Owners: Reliable, high-volume production of certified safety footwear tailored to your market needs.

- For Bulk Clients: Customizable, metal-free solutions that meet strict security and safety standards without compromising on comfort or durability.

Ready to streamline your operations with footwear that won’t slow you down? Contact 3515 today to discuss your requirements and discover how our expertise can benefit your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Why are work shoes important beyond being a fashion accessory? Essential for Safety & Performance

- What are the long-term benefits of following work shoe maintenance tips? Boost Safety & Save Money

- How do industrial safety shoes and specialized work boots ensure safety at heights? Proven Grip and Stability Guide

- What happens during the cutting stage of safety shoes manufacturing? Precision, Process & Quality

- How does the implementation of a safety stock warning system ensure the continuous supply of specialty protective shoes?

- Why might safety toe shoes require a larger size? Ensure a Safe and Comfortable Fit

- What protection features are required for Safety Boots used in LiDAR environments? Essential PPE for Agricultural Zones

- What is the process for evaluating job dangers related to footwear? A Guide to Systematic Hazard Assessment