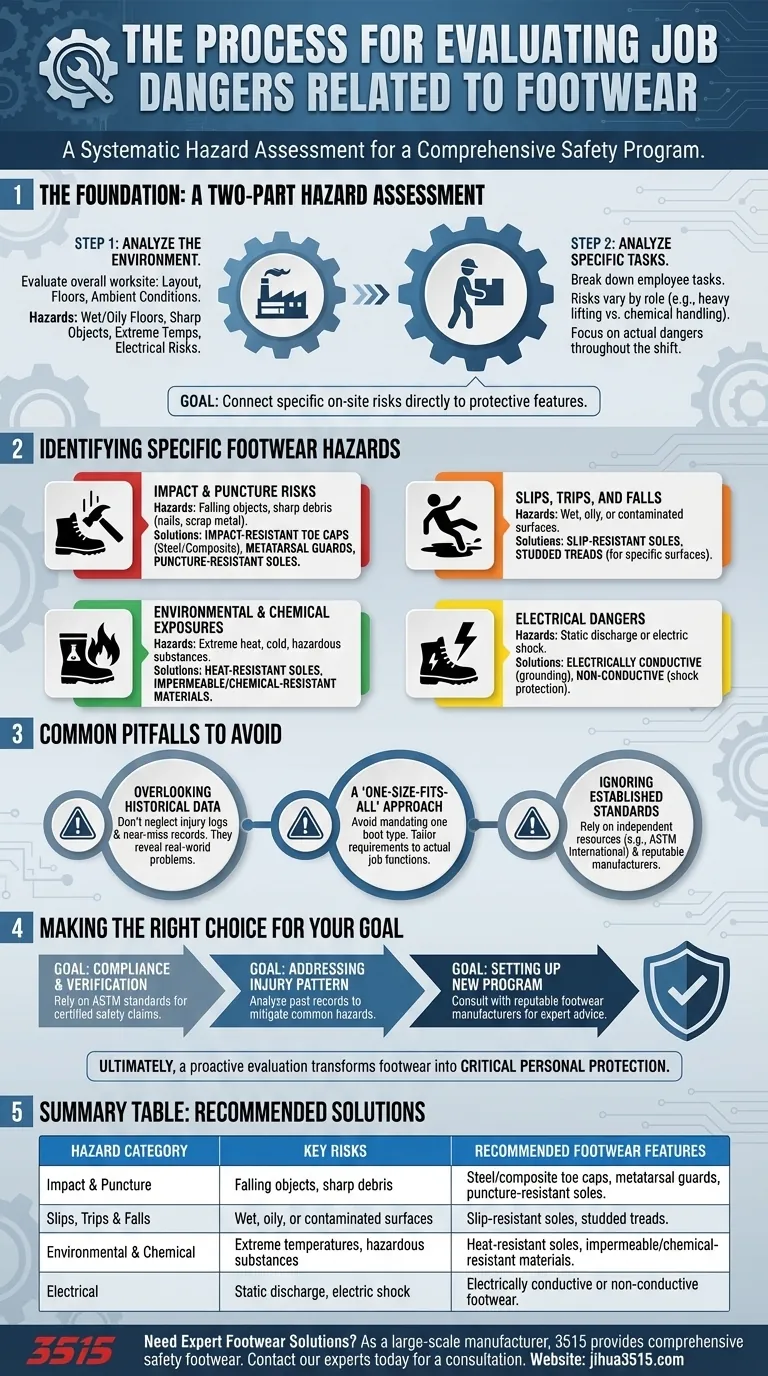

The process for evaluating footwear-related job dangers is a systematic hazard assessment. This involves a direct analysis of the job site and the specific tasks each employee performs to identify potential dangers. Based on this assessment, you can then establish clear recommendations or mandatory rules for the type of footwear employees must wear to ensure their safety.

A comprehensive footwear safety program moves beyond generic rules. It requires a detailed hazard assessment that connects specific on-site risks—from impacts to spills—directly to the protective features of the footwear selected.

The Foundation: A Two-Part Hazard Assessment

A thorough evaluation is not a single action but a continuous process. It begins by looking at the environment and the individual roles within it.

Step 1: Analyze the Environment

First, you must evaluate the overall worksite. Consider the physical layout, floor surfaces, and ambient conditions that could present a danger to an employee's feet.

Look for permanent or common hazards like wet or oily floors, the presence of sharp objects, extreme temperatures, or significant electrical risks.

Step 2: Analyze the Specific Tasks

Next, break down the specific tasks each employee performs. The risks for a worker moving heavy pallets are fundamentally different from those for someone handling liquid chemicals.

This task-based analysis ensures the recommended footwear addresses the actual dangers an employee faces throughout their shift, not just the general dangers of the area.

Identifying Specific Footwear Hazards

Once you understand the environment and tasks, you can categorize the specific hazards that require protection. This allows you to match the problem with the correct footwear solution.

Impact and Puncture Risks

This is one of the most common workplace foot hazards. It involves the risk of objects falling onto or piercing the foot.

Look for tasks involving moving heavy materials or environments with nails, scrap metal, or other sharp debris on the ground. Solutions include impact-resistant toe caps (steel or composite), metatarsal guards, and puncture-resistant soles.

Slips, Trips, and Falls

Slippery surfaces are a leading cause of workplace injury. The risk is elevated in areas with water, oil, or other spills.

Assess floor surfaces and the potential for contamination. The solution is footwear with appropriate slip-resistant soles and studded treads designed for the specific type of surface.

Environmental and Chemical Exposures

Some jobs expose employees to extreme heat, cold, or hazardous substances.

Workers in foundries may need heat-resistant soles, while those in wet environments or around chemicals require footwear made of impermeable or chemical-resistant materials.

Electrical Dangers

Electrical hazards are highly specific. The required footwear depends on whether the goal is to ground the worker or insulate them.

Some tasks require electrically conductive footwear to prevent static discharge, while others demand non-conductive footwear to protect against electric shock.

Common Pitfalls to Avoid

A successful assessment avoids common oversights that can undermine a safety program. Being aware of these pitfalls is critical for creating effective and trusted guidelines.

Overlooking Historical Data

Your own records are a crucial source of information. Do not neglect to review past injury and near-miss logs.

For example, a high rate of foot injuries in a warehouse might reveal that workers wearing sneakers are being injured by falling pallets or in spill areas, highlighting a clear need for mandatory protective boots.

A "One-Size-Fits-All" Approach

Not every employee in a facility faces the same risks. Mandating a single type of heavy-duty boot for all workers can be inefficient and unnecessary.

Tailor footwear requirements to the actual job functions. An office worker entering the shop floor occasionally has different needs than a full-time machine operator.

Ignoring Established Standards

You are not alone in making these decisions. Rely on independent, third-party resources to verify the quality and function of protective footwear.

Organizations like ASTM International provide standards and labeling that allow you to compare features objectively. Reputable manufacturers can also serve as expert resources for your specific industry.

Making the Right Choice for Your Goal

With a completed assessment, you can select footwear with confidence. Your final choice should be guided by your primary objective.

- If your primary focus is compliance and verification: Rely on established standards like those from ASTM International to ensure footwear meets certified safety claims.

- If your primary focus is addressing a known injury pattern: Start by analyzing your past injury records to identify the most common hazards and select footwear that directly mitigates those specific risks.

- If you are setting up a new safety program: Consult with reputable footwear manufacturers who can provide expert recommendations based on your specific workplace hazards and tasks.

Ultimately, a proactive and detailed evaluation process transforms footwear from a uniform requirement into a critical layer of personal protection.

Summary Table:

| Hazard Category | Key Risks | Recommended Footwear Features |

|---|---|---|

| Impact & Puncture | Falling objects, sharp debris | Steel/composite toe caps, metatarsal guards, puncture-resistant soles |

| Slips, Trips & Falls | Wet, oily, or contaminated surfaces | Slip-resistant soles, studded treads |

| Environmental & Chemical | Extreme temperatures, hazardous substances | Heat-resistant soles, impermeable/chemical-resistant materials |

| Electrical | Static discharge, electric shock | Electrically conductive or non-conductive footwear |

Need Expert Footwear Solutions for Your Workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots designed to meet the specific hazards identified in your assessment. We can help you select or customize the right footwear to protect your employees and enhance your safety program.

Contact our experts today for a consultation tailored to your workplace hazards and requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management