In safety shoe manufacturing, the cutting stage is where the blueprint of the shoe first takes physical form. During this critical phase, powerful hydraulic presses use sharp, pre-shaped steel outlines, known as dies, to cleanly cut the individual pieces of the shoe's upper from large sheets of leather or synthetic fabric. This process ensures every component is precisely shaped according to the design specifications.

The cutting stage is fundamentally about achieving perfect, repeatable precision at scale. It transforms a two-dimensional raw material into the foundational components of a three-dimensional safety product, where even minor inaccuracies can compromise the final shoe's integrity, fit, and safety certification.

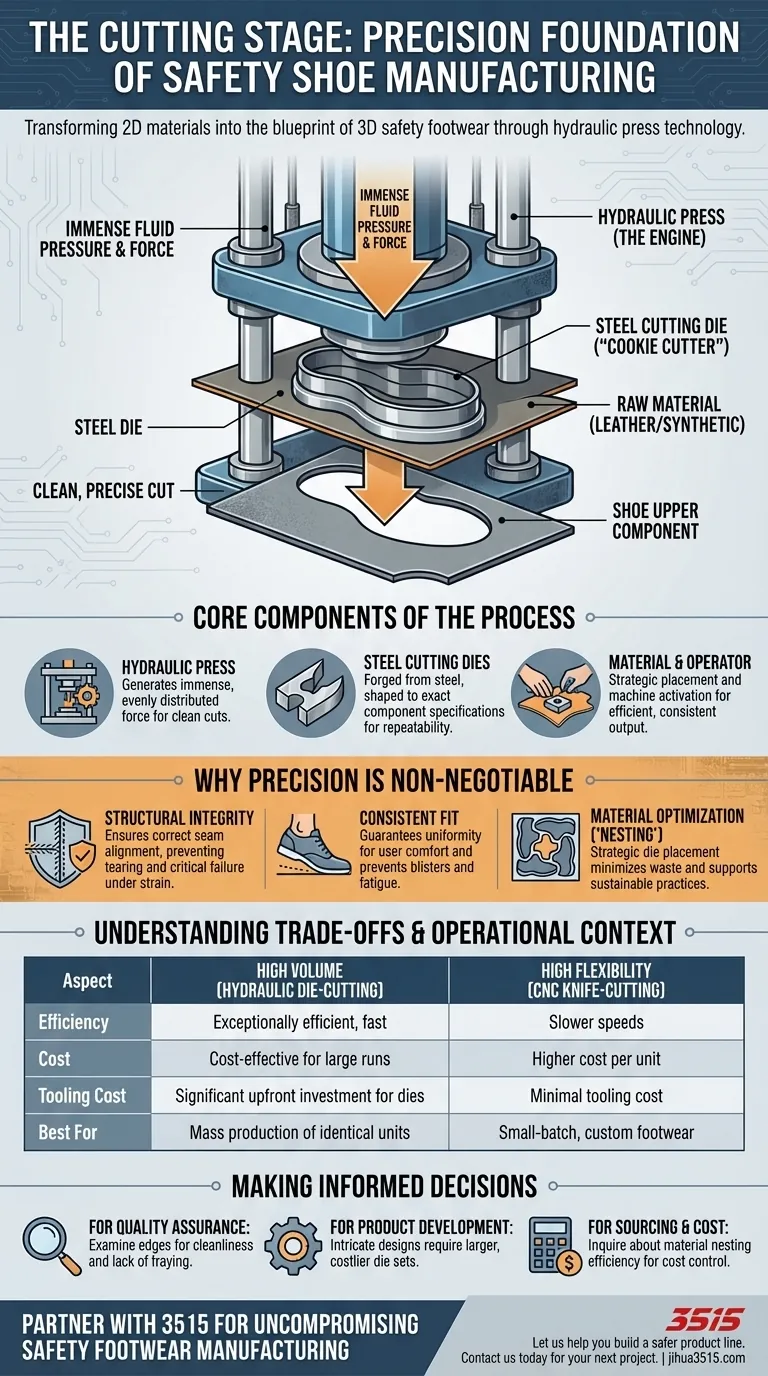

The Mechanics of the Cutting Process

To grasp the importance of this stage, it's essential to understand its core components. The process is a careful marriage of force, precision tooling, and material science.

The Role of the Hydraulic Press

A movable hydraulic press is the engine of the cutting operation. It uses fluid pressure to generate immense, evenly distributed force.

This immense force is necessary to make a single, clean cut through tough and often thick materials like full-grain leather or multi-layered synthetic textiles without causing fraying or distortion.

Understanding the Cutting Dies

A cutting die is essentially an industrial-grade "cookie cutter" forged from steel. Each die is crafted to the exact shape and size of a specific part of the shoe upper, such as the toe cap cover, the heel counter, or the side panels.

A single pair of safety shoes requires multiple dies of various designs to create all its necessary components. The quality and sharpness of these dies are paramount for a clean, precise cut.

From Raw Material to Finished Component

The workflow is systematic. An operator spreads a sheet of leather or synthetic material on the cutting bed of the press.

The appropriate die is placed on the material, and the operator activates the hydraulic press. The machine head lowers, applying tons of pressure and instantly cutting the piece from the master sheet. This process is repeated for every component of the shoe upper.

Why Precision Cutting is Non-Negotiable

In safety footwear, "close enough" is never acceptable. The accuracy established during the cutting stage has direct consequences for the final product's performance and reliability.

Foundation for Structural Integrity

The seams are often the weakest point of any shoe. If components are cut imprecisely, they will not align correctly during the stitching stage.

This misalignment creates uneven tension and stress on the seams, dramatically increasing the risk of tearing or separation under strain—a critical failure for a safety shoe.

Guaranteeing a Consistent Fit

The fit and comfort of a shoe are determined by how well its individual parts come together. Precision-cut components ensure uniformity from the first pair to the ten-thousandth.

This consistency is vital for user comfort during long workdays and is a key factor in preventing blisters, foot fatigue, and other occupational discomforts.

Optimizing Material Usage

Expert operators strategically place the dies on the leather or synthetic sheets to minimize waste, a process known as "nesting."

Efficient nesting not only reduces material costs, which impacts the final price of the shoe, but also supports more sustainable manufacturing practices by conserving resources.

Understanding the Trade-offs

While hydraulic die-cutting is the industry standard for mass production, it's important to recognize its operational context and limitations.

High Volume vs. High Flexibility

Hydraulic die-cutting is exceptionally efficient and cost-effective for producing thousands of identical units. Its speed and repeatability are unmatched for large production runs.

However, for small-batch or custom footwear, the cost of creating a unique set of dies can be prohibitive. In these cases, automated CNC knife-cutting tables, which offer greater flexibility but slower speeds, may be used.

The Upfront Cost of Tooling

Creating a complete set of high-quality steel dies for a new shoe model represents a significant capital investment for the manufacturer.

This initial cost means that design changes cannot be made lightly, as any modification to the pattern requires a new, expensive die to be tooled.

Making the Right Choice for Your Goal

Understanding this foundational manufacturing stage allows you to make more informed decisions, whether you are designing, sourcing, or inspecting safety footwear.

- If your primary focus is quality assurance: Examine the edges of the stitched components. Clean, unfrayed edges indicate sharp dies and a well-calibrated cutting process.

- If your primary focus is product development: Be aware that intricate upper designs with many small, unique panels will require a larger, more expensive set of dies, impacting your tooling budget.

- If your primary focus is sourcing and cost control: Ask potential manufacturing partners about their material nesting efficiency, as this is a key indicator of their operational excellence and ability to manage costs.

Ultimately, recognizing the precision required in the cutting stage empowers you to better assess the foundational quality of the safety footwear you rely on.

Summary Table:

| Aspect | Key Detail | Importance |

|---|---|---|

| Core Process | Hydraulic press uses steel dies to cut leather/synthetic sheets. | Creates the foundational 3D components from 2D material. |

| Key Tool | Pre-shaped steel cutting dies. | Ensures perfect, repeatable precision for every component. |

| Primary Goal | Achieve clean, accurate cuts for all upper parts (toe cap, heel, etc.). | Directly impacts final shoe integrity, fit, and safety certification. |

| Major Consideration | High efficiency for large volumes; upfront cost for die tooling. | Ideal for mass production; less flexible for small custom batches. |

Partner with 3515 for Uncompromising Safety Footwear Manufacturing

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities, including precision hydraulic die-cutting, ensure every pair of safety shoes meets the highest standards of structural integrity, consistent fit, and durability.

Let us help you build a safer product line. Contact our team today to discuss your manufacturing needs and leverage our expertise for your next project.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management