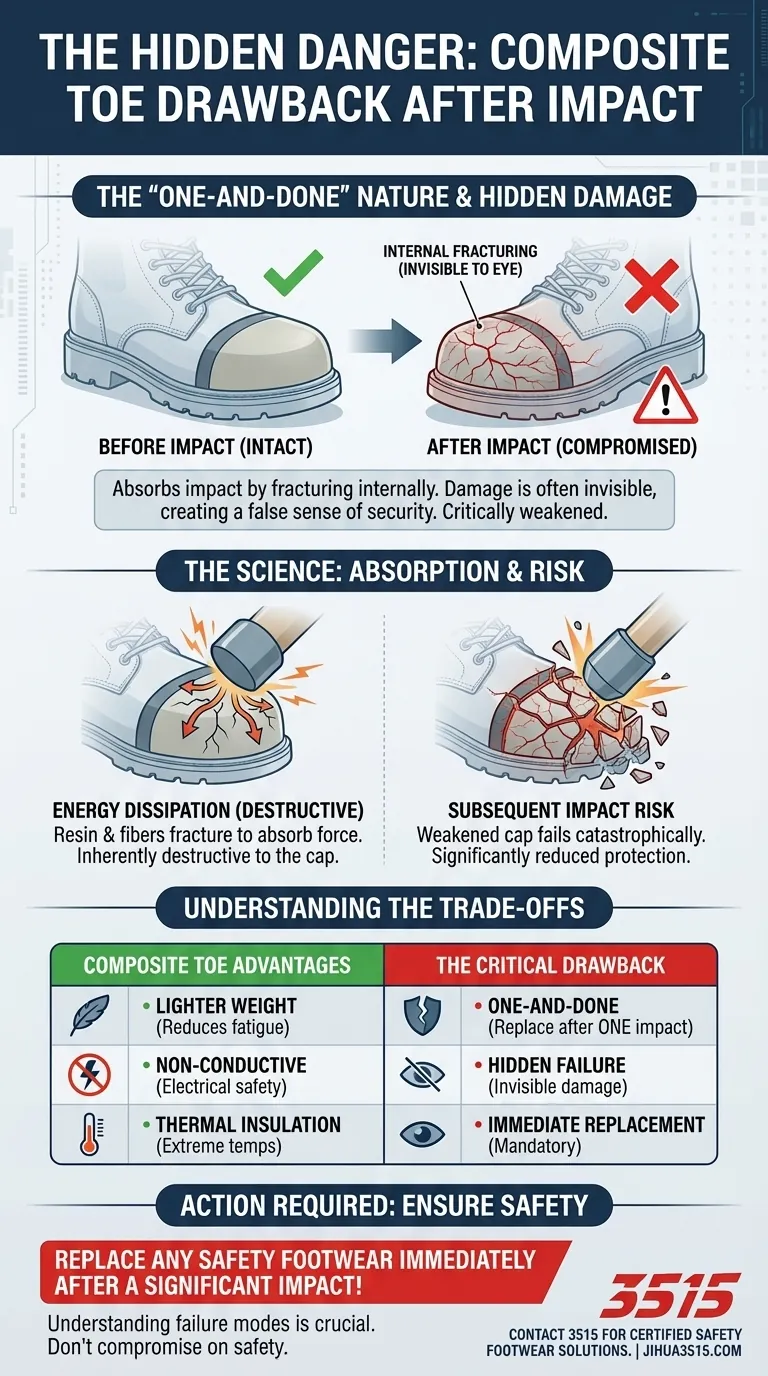

The primary drawback of a composite toe after an impact is its potential for catastrophic failure on a subsequent impact. Unlike steel, which may bend or dent, a composite cap absorbs a severe impact by fracturing internally. This damage is often invisible, creating a false sense of security while leaving the toe cap critically weakened.

The core issue with composite safety toes is their "one-and-done" nature. A single significant impact can compromise their structural integrity entirely, meaning they must be replaced immediately to ensure continued protection, even if there is no visible damage.

How Composite Toes Handle Impact

The Science of Absorption

Composite materials, such as carbon fiber, fiberglass, or Kevlar, are designed to dissipate energy effectively. They do this by allowing their internal resin and fiber structures to fracture and delaminate upon impact.

This process absorbs the dangerous force, protecting your foot as intended. However, this absorption method is inherently destructive to the toe cap itself.

The Problem of Hidden Damage

The most significant risk is that this internal fracturing is often not visible from the outside. The boot may look perfectly fine, but the protective cap has been fundamentally compromised.

This creates a dangerous situation where a worker continues to use footwear that no longer meets safety standards.

The Risk of a Second Impact

A composite toe that has sustained one major impact will offer significantly less protection against a second one. A subsequent drop or compression event could cause the weakened cap to fail completely.

For this reason, any safety footwear with a composite toe that has been involved in a significant impact event must be retired and replaced immediately.

Understanding the Trade-offs

Why Choose Composite Toes?

Despite this drawback, composite toes offer several distinct advantages that make them the superior choice in many environments.

They are significantly lighter than steel toes, reducing foot fatigue over a long workday. They also do not conduct electricity or heat, making them ideal for electricians or those working in extreme temperatures.

Performance vs. Metal Toes

While modern composite toes meet the same ASTM safety standards as steel toes, some high-quality steel and alloy caps can offer a higher absolute limit for impact resistance.

The key difference lies in the failure mode. Steel bends, which can sometimes trap the toes. Composite materials are designed to crack and break apart under loads that exceed their limits, avoiding this specific risk.

The Bottom Line on Replacement

It's critical to understand that any safety footwear, whether steel or composite, that suffers a severe impact should be replaced. The "one-and-done" nature of composite toes is simply more absolute due to the material's hidden failure mode.

Making the Right Choice for Your Work

- If your primary focus is electrical hazard protection: Composite toes are the necessary choice as they do not conduct electricity.

- If your primary focus is comfort and avoiding fatigue: The lighter weight of composite toes offers a significant advantage for long shifts.

- If your primary focus is work in extreme hot or cold: Composite toes provide superior insulation by not transferring temperatures to your feet.

- If your primary focus is surviving a single, maximum-force impact: While both are certified, some believe high-grade metal toes offer a slight edge, but both require immediate replacement after any serious incident.

Ultimately, understanding how your safety equipment functions and fails is the most critical element of workplace safety.

Summary Table:

| Aspect | Composite Toe Drawback |

|---|---|

| Failure Mode | Internal fracturing & delamination upon impact |

| Visibility of Damage | Often invisible; boot appears fine |

| Result | Critically weakened structure; 'one-and-done' protection |

| Required Action | Must be replaced immediately after any significant impact |

Ensure Your Team's Footwear is Safe and Reliable

Understanding the failure modes of safety equipment is crucial for protecting your workforce. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite and steel toe boots, ensuring you get durable, reliable protection tailored to your specific work environment.

Don't compromise on safety. Let us help you equip your team with footwear that meets the highest standards.

Contact 3515 today for a consultation and discover the right safety solution for your needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable & Breathable Training Shoes for Custom Brands

People Also Ask

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection