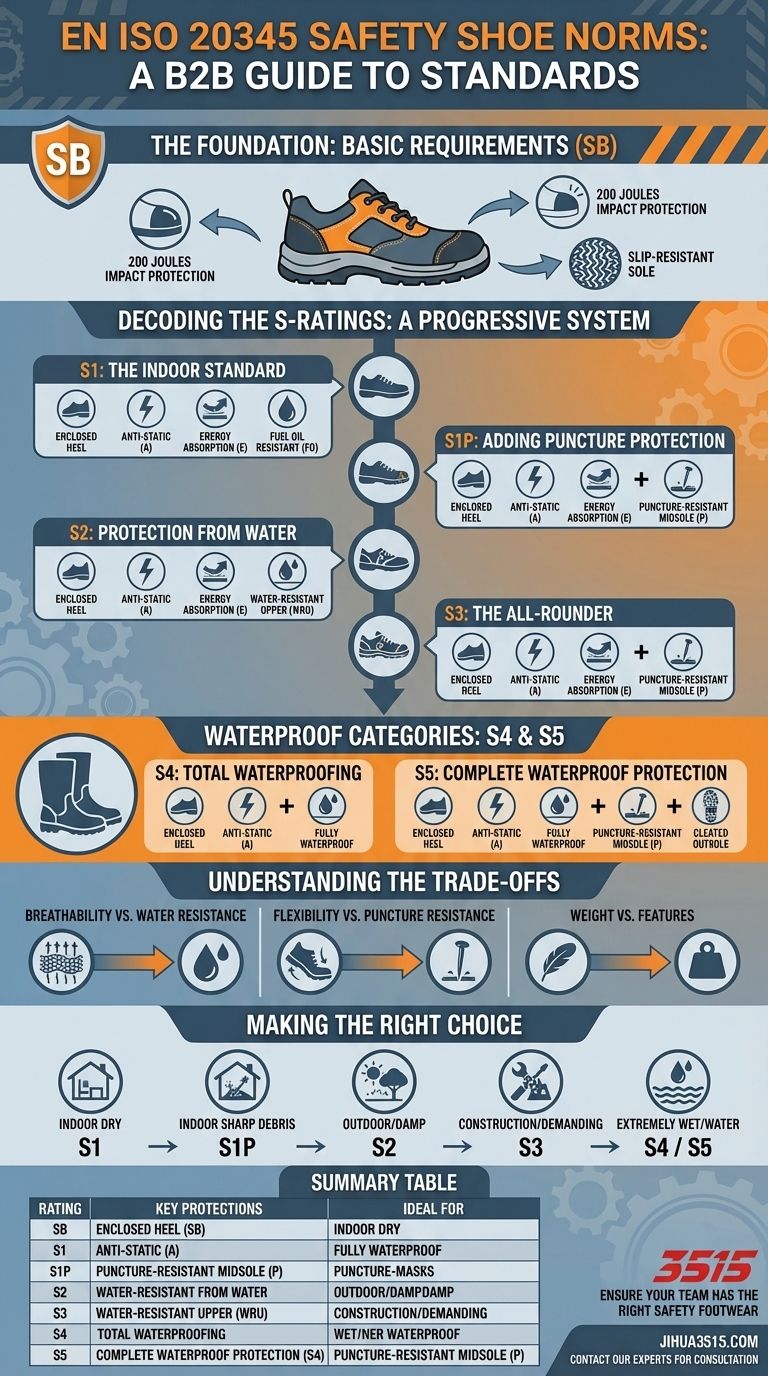

At its core, the EN ISO 20345 standard is the European benchmark that defines the minimum requirements for safety footwear. Any footwear certified under this standard must, at a minimum, feature a toe cap capable of withstanding 200 joules of impact. From this baseline, different categories add layers of specific protections against various workplace hazards.

The standard isn't a single rule but a progressive system. It starts with basic toe protection (SB) and builds upon it with codes like S1, S2, and S3, each adding features like puncture resistance or water resistance to match increasingly demanding work environments.

The Foundation: Basic Requirements (SB)

All safety footwear certified under EN ISO 20345 must meet the "Safety Basic" or SB requirements. This is the non-negotiable foundation upon which all other ratings are built.

Protective Toecap

The single most critical feature of any SB-rated shoe is a toe cap that provides 200-joule impact protection. This shields the wearer's toes from heavy falling objects.

Slip-Resistant Sole

The outsole must meet minimum slip-resistance standards. This ensures a baseline level of grip on common surfaces, although higher ratings for specific conditions exist.

Decoding the S-Ratings: A Progressive System

Beyond the SB baseline, the "S-ratings" classify footwear based on an escalating set of protective features. Each step up incorporates the features of the level below it.

S1: The Indoor Standard

An S1 shoe includes all the basic SB requirements and adds several key features for indoor work.

It has a fully enclosed heel, anti-static properties (A), and energy absorption in the heel (E). The sole is also resistant to fuel oil (FO).

S1P: Adding Puncture Protection

The S1P rating is one of the most common. It is simply an S1 shoe with the addition of a puncture-resistant midsole (P). This protects the foot from sharp objects like nails penetrating from below.

S2: Protection from Water

An S2 shoe contains all the protective elements of an S1 shoe. Its key addition is a water-resistant upper (WRU), which prevents water penetration and absorption for a limited time.

S3: The All-Rounder

S3 is a highly comprehensive rating, making it a standard for construction and general outdoor work. It combines all the features of an S2 shoe (including the water-resistant upper) with the puncture-resistant midsole (P) found in S1P footwear.

Waterproof Categories: S4 & S5

These categories are distinct and typically apply to fully molded rubber or polymeric footwear, such as Wellington boots, designed for wet environments.

S4: Total Waterproofing

An S4 boot offers all the protection of the S1 level (toe protection, anti-static, energy absorption, fuel oil resistance) but in a fully waterproof and leak-proof construction.

S5: Complete Waterproof Protection

S5 is the highest rating for this type of footwear. It provides all the benefits of an S4 boot but adds a puncture-resistant midsole (P) and a cleated outsole for superior grip.

Understanding the Trade-offs

Selecting the right safety footwear involves balancing protection with comfort and practicality. No single shoe is perfect for every task.

Breathability vs. Water Resistance

Footwear rated S2 or S3 has a water-resistant upper. While this is excellent for damp conditions, it inherently reduces the material's breathability compared to an S1 or S1P shoe.

Flexibility vs. Puncture Resistance

A puncture-resistant midsole (found in S1P, S3, S5) is critical for many jobs. However, traditional steel midsoles can reduce flexibility. Modern composite alternatives offer improved flexibility but can come at a different price point.

Weight vs. Features

As a general rule, the more protective features a shoe has, the heavier it may be. An S3 boot will almost always be heavier than an S1 boot due to the added midsole and more robust upper materials.

Making the Right Choice for Your Environment

Your specific workplace hazards should dictate your choice. Use the ratings as a guide to match the footwear directly to the risks you face.

- If your primary focus is indoor work in a dry environment with no sharp ground hazards: An S1 shoe provides the necessary baseline protection.

- If your primary focus is indoor work with a risk of nails or sharp debris: S1P is the essential choice for its puncture resistance.

- If your primary focus is outdoor work or frequent exposure to damp conditions: S2 provides the water resistance you need, assuming no puncture risk.

- If your primary focus is construction, engineering, or demanding outdoor work: An S3 shoe offers the most complete combination of protection against impact, water, and puncture hazards.

- If your primary focus is working in standing water or extremely wet environments: S4 or S5 boots are the only options that provide full waterproof integrity.

By understanding these codes, you can move beyond simple compliance and actively choose the precise level of safety your work demands.

Summary Table:

| Rating | Key Protections (Beyond SB Toe Cap) | Ideal For |

|---|---|---|

| SB | Basic toe protection, slip-resistant sole | Minimum requirement for all safety footwear |

| S1 | Enclosed heel, anti-static (A), energy absorption (E), fuel oil resistant sole (FO) | Indoor, dry environments |

| S1P | All S1 features + Puncture-resistant midsole (P) | Indoor work with sharp debris risk |

| S2 | All S1 features + Water-resistant upper (WRU) | Outdoor/damp environments (no puncture risk) |

| S3 | All S2 features + Puncture-resistant midsole (P) | Construction, demanding outdoor work |

| S4 | All S1 features in a fully waterproof, leak-proof construction (e.g., rubber boots) | Wet environments, standing water |

| S5 | All S4 features + Puncture-resistant midsole (P) + Cleated outsole | Extremely wet environments with puncture hazards |

Ensure Your Team Has the Right Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the precise level of protection, comfort, and durability your workforce needs.

Let us help you match the right safety standard to your specific hazards.

Contact our experts today for a consultation and discover how we can support your safety and supply requirements.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- How do SCR and HRV sensors assess safety shoe comfort? Quantifying Ergonomic Stress and Fatigue

- What is the primary function of protective footwear in poultry biosecurity? Maximize Flock Health and Biosecurity

- How do high-quality safety shoes prevent musculoskeletal disorders? Enhance Worker Safety & Biomechanical Support

- How do PPE and safety shoes safeguard operators during pesticide spraying? Essential Gear for Chemical Protection

- What toe options are available for oil-resistant safety boots? Find the Right Fit for Your Job

- What are some technical features available in safety shoes? A Guide to Workplace Foot Protection

- What are the primary functions of professional protective consumables? Crucial Construction Safety Gear Explained

- What are the advantages of leather as a material for motorcycle boots? Unmatched Safety & Long-Term Comfort