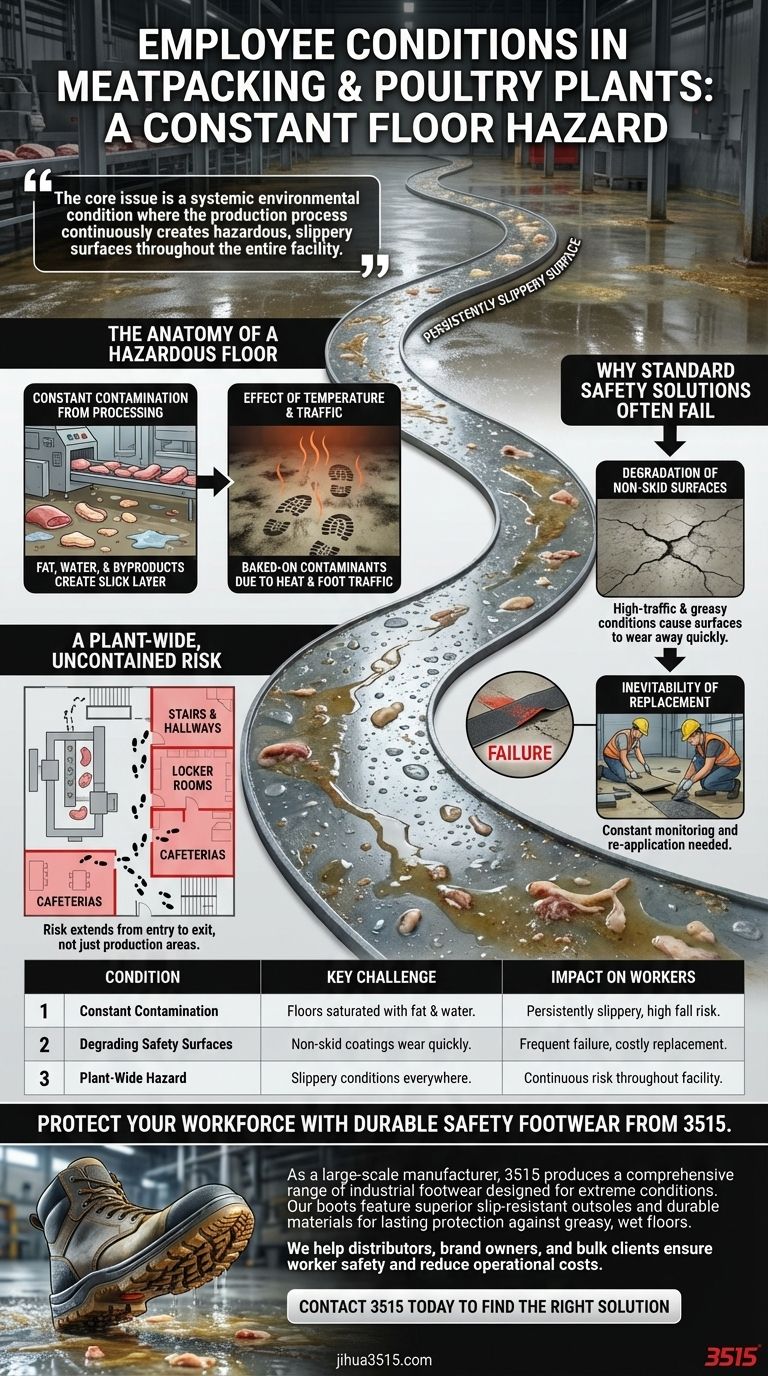

The fundamental condition faced by employees in meatpacking and poultry slaughter plants is a constant and pervasive physical hazard underfoot. Workers must navigate floors that are persistently slippery due to an environment saturated with water, animal fat, and other production byproducts.

The core issue is not occasional spills, but a systemic environmental condition where the production process itself continuously creates hazardous, slippery surfaces throughout the entire facility, rendering simple non-skid solutions ineffective over time.

The Anatomy of a Hazardous Floor

The slippery conditions in these plants are not accidental; they are a direct result of the operational environment. Several factors combine to create a persistent risk of slips and falls.

Constant Contamination from Processing

The primary source of the hazard is the material being processed. Surfaces are described as being littered with pieces of fat and other product, which mix with the water used in processing and cleaning.

This creates a slick, unstable layer on top of the walking surface. The problem originates directly on the production line but does not remain there.

The Effect of Temperature and Traffic

Environmental factors compound the problem significantly. The combination of plant temperatures and heavy foot traffic causes the residual fat to adhere firmly to the floor.

This process essentially bakes the slippery contaminant onto the surface, making it difficult to remove and creating a dangerously low-friction environment for workers.

Why Standard Safety Solutions Often Fail

While facilities may implement safety measures, the unique conditions of a meat or poultry processing plant create a cycle of maintenance and failure for common solutions.

The Degradation of Non-Skid Surfaces

Facilities often use non-skid surfacing products to mitigate the risk. However, the same high-traffic and wet, greasy conditions cause these surfaces to wear away quickly.

This means that a surface deemed safe one week can become a significant hazard the next, requiring constant monitoring and re-application.

The Inevitability of Replacement

The degradation of safety surfaces is not a matter of if, but when. The reference notes that these products need constant replacement to remain effective.

This transforms floor safety from a one-time installation into a continuous and demanding maintenance challenge.

A Plant-Wide, Uncontained Risk

A critical aspect of this condition is that the hazard is not confined to the immediate processing area where the animals are handled.

Beyond the Production Line

The slippery conditions extend throughout the plant. This includes common transit areas like stairs and hallways that employees must use to move between work areas.

Risk in Non-Production Zones

The hazard follows employees even when they are off the line. The same slippery floors are found in areas like locker rooms and cafeterias, meaning workers are exposed to the risk of slips and falls for the duration of their time in the facility.

Key Implications for Safety and Operations

Understanding these conditions leads to clear conclusions for anyone assessing the work environment in these plants.

- If your primary focus is worker safety: Recognize that the risk of slipping is not an isolated event but a constant, facility-wide environmental hazard that exists from the moment an employee enters until they leave.

- If your primary focus is facility management: Acknowledge that merely installing non-skid flooring is an incomplete solution; a durable, long-term strategy must account for constant wear and systematic re-application or replacement.

Ultimately, the physical environment in these plants is defined by a persistent and widespread hazardous condition created by the very nature of the work.

Summary Table:

| Condition | Key Challenge | Impact on Workers |

|---|---|---|

| Constant Contamination | Floors saturated with water, fat, and byproducts. | Creates a persistently slippery surface, increasing fall risk. |

| Degrading Safety Surfaces | Non-skid coatings wear away quickly from traffic and grease. | Safety measures fail, requiring constant and costly replacement. |

| Plant-Wide Hazard | Slippery conditions extend to hallways, stairs, and cafeterias. | Risk of injury exists from the moment an employee enters the facility. |

Protect your workforce with durable safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear designed for the extreme conditions of meatpacking and poultry plants. Our boots are engineered with superior slip-resistant outsoles and durable materials to provide lasting protection against greasy, wet floors.

We help distributors, brand owners, and bulk clients ensure worker safety and reduce operational costs associated with slips and falls.

Contact 3515 today to find the right safety footwear solution for your facility.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What are the key design considerations for high-friction anti-slip outsoles? Master Safety with Advanced Tread Science

- Why is friction coefficient testing on wet surfaces essential? Science-Backed Slip Resistance Secrets

- What features should one look for in non-slip restaurant shoes? Find the Best for Safety & Comfort

- Why do restaurant workers face higher slipping hazards? The Inherent Risks of a Fast-Paced Environment

- How do non-slip shoes differ from slip-resistant shoes? Uncover the Key to Workplace Safety

- What industries commonly require slip resistant shoes? Essential Guide for Workplace Safety

- How do high friction coefficient anti-slip outsoles contribute to workplace safety? Maximize Industrial Traction

- Why are non-slip shoes vital for workers? Essential Engineering for Workplace Safety