Yes, wax treatment will cause stiffness in the treated material, particularly after it has cooled. This change is a normal and expected characteristic of the waxing process, resulting from the wax solidifying within the material's fibers. The degree of stiffness is a critical factor to consider if the item's flexibility is essential for its function.

The core principle to understand is that stiffness is not a flaw of wax treatment, but a direct trade-off for increased durability and water resistance. Your primary task is to decide if that trade-off is acceptable for your specific item and its intended use.

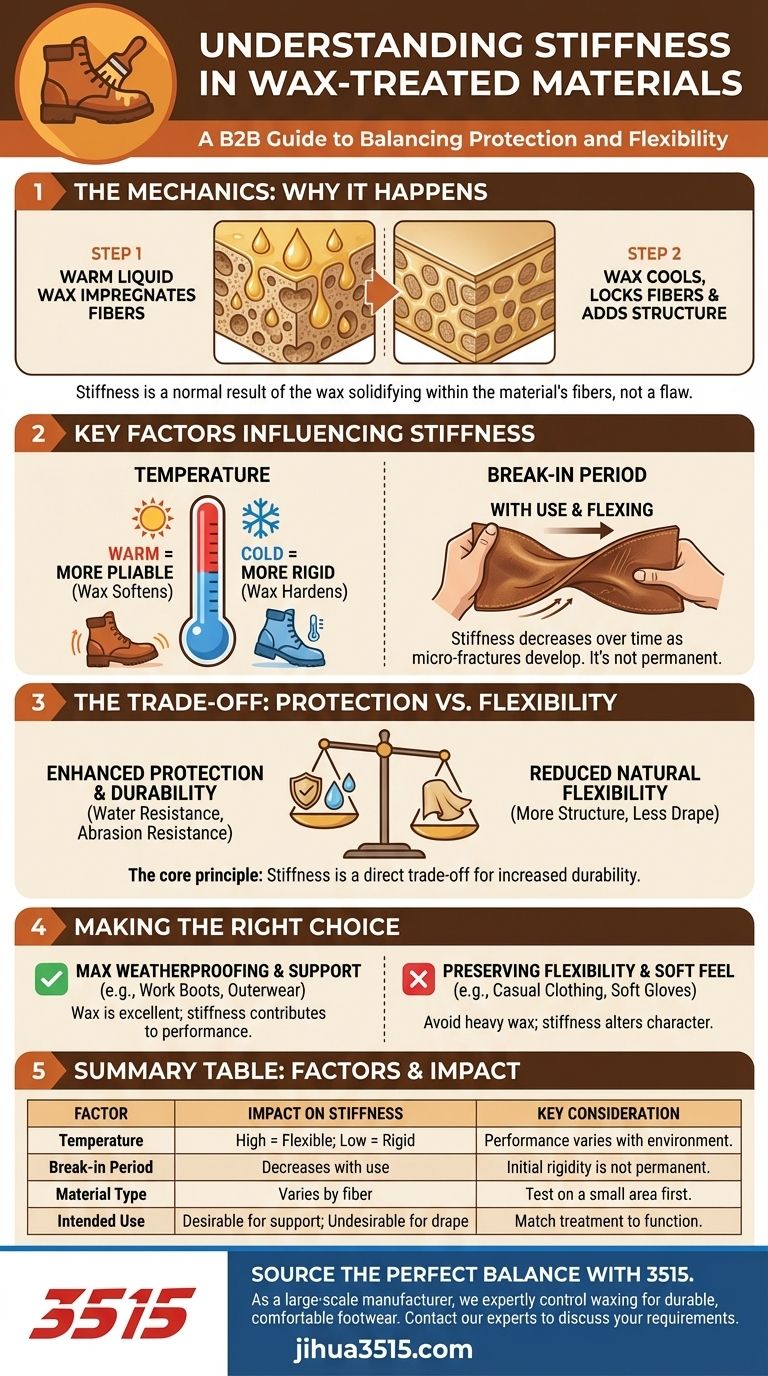

The Mechanics of Wax-Induced Stiffness

To make an informed decision, you must first understand why the stiffness occurs and how it behaves. The effect is not simply a surface coating; it's an impregnation of the material itself.

Why Wax Causes Stiffness

When you apply warm, liquid wax to a material like leather or canvas, it soaks deep into the fibrous structure. As the wax cools and returns to a solid state, it essentially locks these fibers in place. This impregnation adds structure and rigidity, restricting the micro-movements between fibers that allow the material to be pliable.

The Role of Temperature

The stiffness of a waxed item is not static. It is directly influenced by temperature.

When the item is warm—from body heat, ambient temperature, or direct sunlight—the wax softens slightly. This allows the material's fibers to move more freely, making the item feel more supple and flexible.

Conversely, in colder conditions, the wax becomes harder and more rigid. This further restricts fiber movement, resulting in a noticeably stiffer product. This is why a waxed jacket may feel rigid when you first put it on but becomes more pliable as it warms up.

Is the Stiffness Permanent?

The initial, pronounced stiffness you feel immediately after treatment is not permanent. With use, the material will "break in."

As the item is flexed, bent, and worn, the solid wax coating develops micro-fractures and adapts to the movement. This process gradually restores a significant degree of flexibility, though the material will likely never be as soft as its untreated state.

Understanding the Trade-offs

Applying wax is a balancing act between protection and pliability. Recognizing the inherent compromises is key to using the treatment effectively.

The Benefit: Protection and Durability

The same wax that causes stiffness is what provides the primary benefits. By filling the gaps between fibers, it creates a formidable barrier against water. It also protects the fibers themselves from abrasion and wear, significantly extending the life of the item.

The Cost: Reduced Flexibility

The unavoidable downside is a reduction in the material's natural flexibility. For an item like a heavy-duty work boot, this added structure can be a desirable feature, providing more support. For an item that requires drape and soft movement, like a shirt or a lightweight bag, the stiffness can be a significant drawback.

Making the Right Choice for Your Application

Evaluate your goal before you commit to a wax treatment. The item's intended function should be your primary guide.

- If your primary focus is maximum weatherproofing and support: Wax treatment is an excellent choice, as the resulting stiffness contributes positively to the item's performance (e.g., work boots, tool rolls, or rugged outerwear).

- If your primary focus is preserving the original flexibility and feel: You should avoid heavy wax treatments, as the stiffness will fundamentally alter the character of the material (e.g., casual clothing, soft leather gloves, or items requiring a soft drape).

By understanding that stiffness is an integral part of the waxing process, you can leverage this treatment as a precise tool to enhance the items that will benefit from it.

Summary Table:

| Factor | Impact on Stiffness | Key Consideration |

|---|---|---|

| Temperature | High temp = more flexible; Low temp = more rigid | Performance varies with environment. |

| Break-in Period | Stiffness decreases with use | Initial rigidity is not permanent. |

| Material Type | Varies by fiber (e.g., leather, canvas) | Test on a small area first. |

| Intended Use | Desirable for support; Undesirable for drape | Match the treatment to the product's function. |

Need to source wax-treated footwear that balances durability with the right level of flexibility?

As a large-scale manufacturer, 3515 produces a comprehensive range of waxed leather boots and shoes for distributors, brand owners, and bulk clients. We expertly control the waxing process to achieve the perfect balance of weatherproof protection and comfort for your target market.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

People Also Ask

- What should you do when your work boots no longer serve their purpose? Don't Gamble with Your Safety

- Where can heavy duty work boots be purchased? Find the Right Supplier for Your Needs

- What distinguishes moc toe boots? The Ultimate Guide to Unmatched Comfort & Style

- What are the requirements for compression resistance in safety toe boots? Ensure OSHA & ASTM F2413 Compliance

- What should delivery drivers look for in work shoes? Essential Features for Safety & Comfort

- How do the men's 11-inch pull-on boots improve upon the original version? Lighter, More Flexible Design for All-Day Comfort

- What factors should be considered beyond safety standards when choosing work boots? Ensure All-Day Comfort & Durability

- Why is foot protection important in work boots? Prevent 60,000 Annual Injuries