The suitability of Mortar boots for corrosive environments stems directly from their specific material composition and a modern construction method that eliminates traditional points of failure. They are built entirely from synthetic materials, feature a specialized Thermoplastic Polyurethane (TPU) outsole, and use a direct injection chemical bond instead of conventional stitching.

The core principle behind the Mortar boot's resilience is the replacement of materials and construction techniques vulnerable to chemical attack—like leather and thread—with inherently resistant synthetic polymers and a seamless chemical bond.

Deconstructing the Protective Design

To understand their effectiveness, we need to analyze the two key components that face the most abuse in harsh environments: the upper material and the sole construction.

The Advantage of Synthetic Uppers

Unlike natural leather, which can dry out, crack, and degrade when repeatedly exposed to chemicals, the synthetic materials used in Mortar boots are inherently more stable. This makes them effectively maintenance-free in corrosive settings where leather would require constant cleaning and conditioning to survive.

A Chemically Resistant Outsole

The outsole is engineered with TPU (Thermoplastic Polyurethane), a material specifically chosen for its high resistance to abrasion and, critically, to oils and chemicals. This "all-weather" compound has been tested in demanding environments like the Canadian oil sands, proving its durability against petroleum-based corrosion.

Eliminating the Weakest Link: The Stitching

The most significant design choice for corrosive environments is the use of direct injection technology. This process chemically bonds the upper part of the boot directly to the outsole compound.

Traditional boots rely on stitched seams to join the upper and the sole. In corrosive environments, these threads are a primary point of failure, as chemicals will attack and dissolve the stitching long before the sole or upper material gives way. The seamless chemical bond of the Mortar boot completely eliminates this vulnerability.

Understanding the Trade-offs

No design is without its compromises. The features that make these boots exceptionally durable in corrosive settings also introduce specific trade-offs compared to traditional footwear.

Breathability and Material Feel

While highly resilient, synthetic materials typically offer less breathability than high-quality natural leather. This is a common consideration for any synthetic work boot, especially for long-term wear in warm conditions.

The Question of Repairability

Direct injection bonding creates an incredibly strong and permanent seal between the upper and the sole. A significant consequence of this method is that the boots cannot be resoled. Unlike traditionally stitched boots that can be repaired, this construction prioritizes initial durability over long-term serviceability.

Making the Right Choice for Your Goal

The engineering behind the Mortar boot is purpose-driven. Your decision should be based on the primary challenge you face.

- If your primary focus is maximum durability in environments with oils, chemicals, and corrosive agents: The combination of a synthetic upper, a TPU outsole, and direct injection bonding provides superior resistance to chemical degradation.

- If your primary focus is long-term repairability and the breathability of natural materials: You may prefer a traditionally stitched leather boot, but you must accept its inherent vulnerability to chemical attack and commit to a rigorous maintenance schedule.

Ultimately, choosing the correct footwear means matching its construction directly to the demands of your work environment.

Summary Table:

| Feature | Benefit for Corrosive Environments |

|---|---|

| Synthetic Uppers | Inherently resistant to chemicals; maintenance-free compared to leather. |

| TPU Outsole | High resistance to abrasion, oils, and chemical corrosion. |

| Direct Injection Bonding | Eliminates stitched seams, the primary failure point for chemical attack. |

| Trade-off | Consideration: Not resoleable; prioritizes initial durability over repairability. |

Need Durable Footwear for Demanding Environments?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including chemically resistant models like the Mortar boot.

We can help you:

- Source Reliable PPE: Equip your workforce with boots built to withstand harsh conditions.

- Develop Custom Solutions: Create branded or application-specific footwear for your market.

- Ensure Bulk Supply: Meet large-volume orders with consistent quality and competitive pricing.

Let's discuss your specific needs. Contact our team today to find the perfect protective footwear solution for your business.

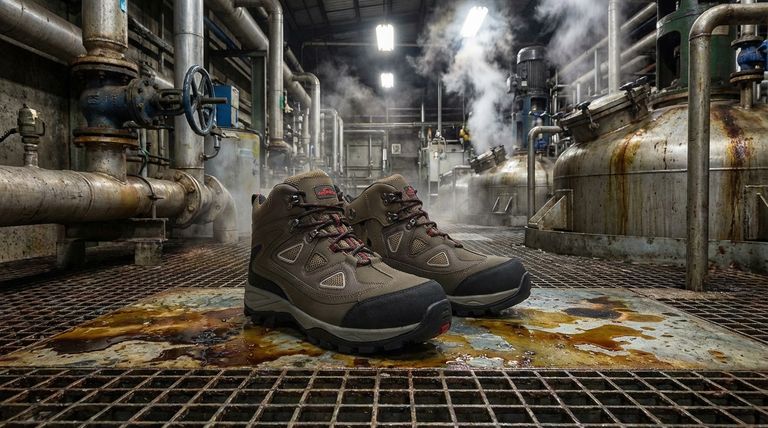

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management