Selecting the right safety shoe is a critical decision that directly impacts worker safety, comfort, and productivity. The most important factors to consider are the specific hazards of the work environment, the protective materials of the shoe itself, and the individual fit and support required for the worker who will be wearing it for extended periods.

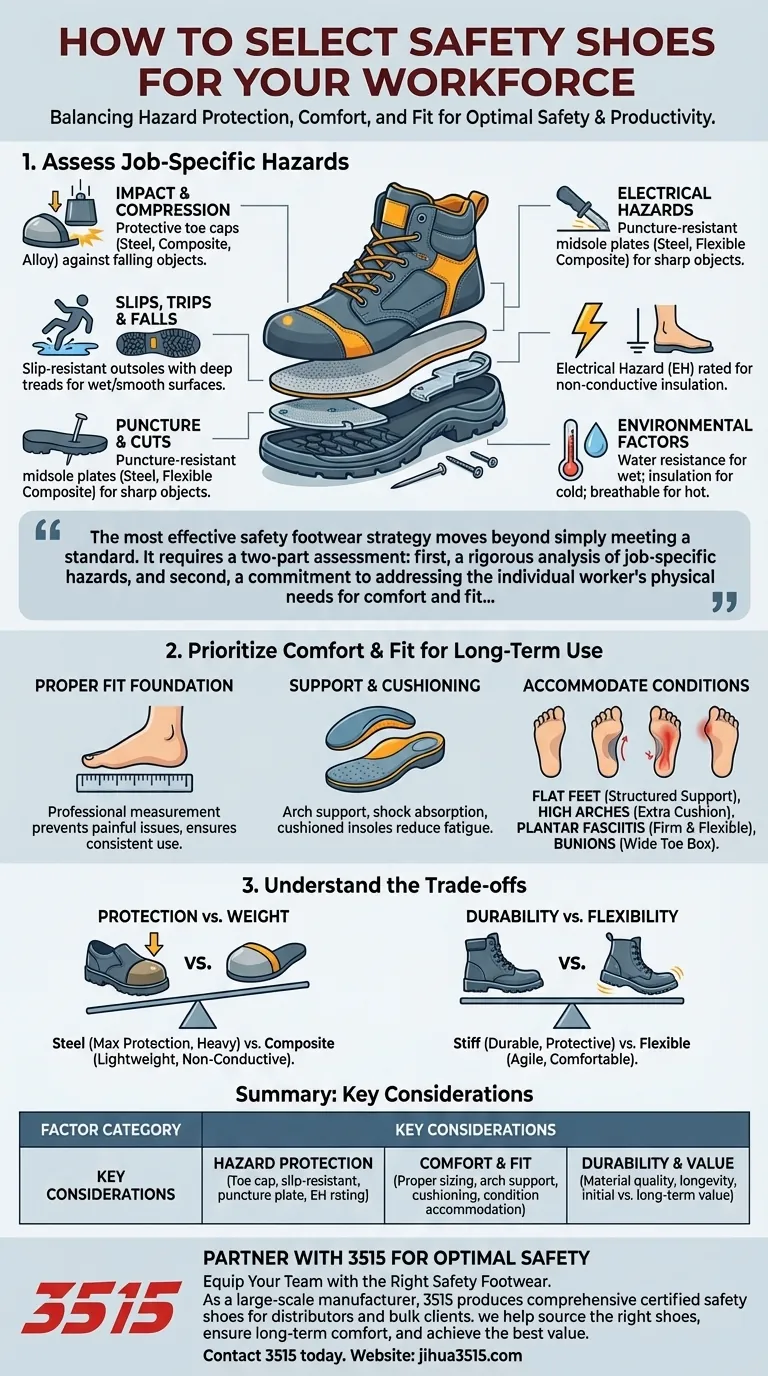

The most effective safety footwear strategy moves beyond simply meeting a standard. It requires a two-part assessment: first, a rigorous analysis of job-specific hazards, and second, a commitment to addressing the individual worker's physical needs for comfort and fit, which ensures consistent use and long-term well-being.

Start with the Hazard: A Job-Specific Risk Assessment

Before considering any shoe, you must first understand the environment it will be used in. A shoe designed for a construction site is fundamentally different from one needed in a commercial kitchen.

Impact and Compression

This is the most common hazard, involving falling objects or heavy rolling equipment. The primary defense is the protective toe cap. Options typically include steel, composite, or alloy toes, each offering certified protection against impact forces.

Slips, Trips, and Falls

According to safety data, slips and falls are a leading cause of nonfatal workplace injuries. A shoe's outsole is the critical feature here. Look for slip-resistant materials like rubber or polyurethane (PU) combined with deep tread patterns designed to channel away liquids on wet or smooth surfaces.

Puncture and Cuts

Environments with sharp objects like nails, scrap metal, or glass require puncture-resistant footwear. This is achieved with a protective plate in the midsole of the shoe, often made of steel or flexible composite materials.

Electrical Hazards

For those working near live electrical circuits, Electrical Hazard (EH) rated shoes are essential. These are designed with non-conductive materials to insulate the wearer from the ground, reducing the risk of shock.

Environmental Factors

Consider the ambient conditions. Water resistance is crucial for outdoor or wet environments, while insulated shoes are necessary for cold protection. In hot conditions, breathable materials are key to managing heat and sweat.

Beyond Protection: The Critical Role of Comfort and Fit

A safety shoe is useless if it's too uncomfortable to wear correctly and consistently. Long-term comfort is not a luxury; it is a core component of safety and productivity.

The Foundation of Proper Fit

An ill-fitting shoe can cause blisters, bunions, and other painful foot issues. It is highly recommended to have workers professionally measured, as sizes can vary between brands. A proper fit prevents foot fatigue and encourages correct use.

Support and Cushioning for Long Days

Workers who spend hours on their feet experience significant physical strain. Features like proper arch support, shock-absorbing midsoles, and cushioned insoles are vital. They work together to alleviate stress on the feet, legs, and back, directly reducing fatigue and improving focus.

Accommodating Specific Foot Conditions

Every worker is different. Be mindful of common foot conditions that require specific features.

- Flat feet benefit from shoes with structured arch support.

- High arches need extra cushioning and shock absorption.

- Plantar fasciitis requires a combination of firm arch support and flexibility.

- Bunions demand a shoe with a wide toe box and flexible upper materials.

Understanding the Trade-offs

Choosing the perfect safety shoe often involves balancing competing factors. Being aware of these trade-offs allows you to make a more informed decision.

Protection vs. Weight

Historically, steel toes have been the standard for maximum protection, but they add significant weight. Composite toes are much lighter, don't conduct cold, and won't set off metal detectors, but can be slightly bulkier to achieve the same safety rating.

Durability vs. Flexibility

The most rugged, durable outsole materials can sometimes be stiff. This may provide excellent longevity and protection but can reduce comfort and flexibility for workers who need to crouch or be agile.

Initial Cost vs. Long-Term Value

It can be tempting to select a lower-cost option. However, cheaper shoes often use less supportive materials that break down quickly, leading to higher replacement costs and potential productivity loss from worker fatigue and discomfort.

Making the Right Choice for Your Team

Use your risk assessment and understanding of your workers' needs to guide your final selection.

- If your primary focus is heavy industrial hazards (construction, manufacturing): Prioritize shoes with certified steel or composite toes and puncture-resistant midsole plates.

- If your primary focus is slippery environments (kitchens, food processing): The most critical feature is a high-traction, slip-resistant outsole with a deep, liquid-channeling tread.

- If your primary focus is long periods of standing or walking (logistics, warehouses): Emphasize lightweight design, superior cushioning, and proper arch support to combat fatigue.

- If your primary focus is work around live electricity: You must select footwear with the correct Electrical Hazard (EH) rating to ensure insulation.

A well-chosen safety shoe is an investment in the health, safety, and performance of your team.

Summary Table:

| Factor Category | Key Considerations |

|---|---|

| Hazard Protection | Toe cap (steel/composite), slip-resistant sole, puncture-resistant plate, EH rating |

| Comfort & Fit | Proper sizing, arch support, cushioning, accommodation for foot conditions |

| Durability & Value | Material quality, outsole longevity, initial cost vs. long-term value |

Equip Your Team with the Right Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear tailored to your specific industry hazards and worker needs.

We can help you:

- Source the right shoes based on your detailed risk assessment.

- Ensure long-term comfort with ergonomic designs that workers will wear consistently.

- Achieve the best value with durable products that reduce replacement costs and boost productivity.

Contact 3515 today for a consultation and let us help you protect your most valuable asset—your workforce.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What has driven the increased demand for safety gear designed for women? The Rise of Women in Industrial Trades

- What are the changes to puncture resistance in the new EN ISO 20345 standard? Understand P, PL, and PS Markings

- What should be considered when making the final decision on work shoes? A Guide to Perfect Fit and Safety

- What is the importance of professional rubber safety boots for skin protection? Ensure High-Level Agricultural Safety

- How do pressure sensor-based systems contribute to the design of stable Safety Shoes? Engineering Data-Driven Stability

- How do inorganic nanomaterials improve leather environmental resistance? Boost Durability for Safety Footwear

- What is the necessity of professional protective gear for special populations? Ensure Safe Exercise and Joint Stability

- Why is choosing the right safety shoes important? Mitigate Workplace Hazards and Boost Productivity