The most significant change to puncture resistance in the new EN ISO 20345 standard is the introduction of specific tests and markings for non-metallic inserts. While the test for traditional metallic inserts remains the same, the update now distinguishes between protection against large and small diameter hazards for fabric-based midsoles, using the new "PL" and "PS" markings to provide greater clarity on the level of protection offered.

The new standard moves beyond a one-size-fits-all approach to puncture resistance. It forces a more precise risk assessment by distinguishing between protection from broad, large-nail hazards (PL) and the more challenging risk of smaller, piercing objects (PS).

The Rationale Behind the New Standard

The updated standard reflects a deeper understanding of modern workplace hazards and the materials used to combat them. The goal is to align the certified protection level more closely with real-world risks.

Limitations of the Old System

Previously, a single "P" marking was used for any midsole that passed the puncture test, which used a 4.5mm diameter test nail. This created ambiguity, as some flexible, non-metallic midsoles could be compromised by smaller, sharper objects like fine nails or wires, even if they passed the standard test.

Aligning Protection with Real-World Risks

The revision acknowledges that the nature of puncture hazards varies significantly between job sites. By creating distinct tests for different threat sizes, the standard empowers safety managers and workers to choose footwear that is precisely suited to their specific environment.

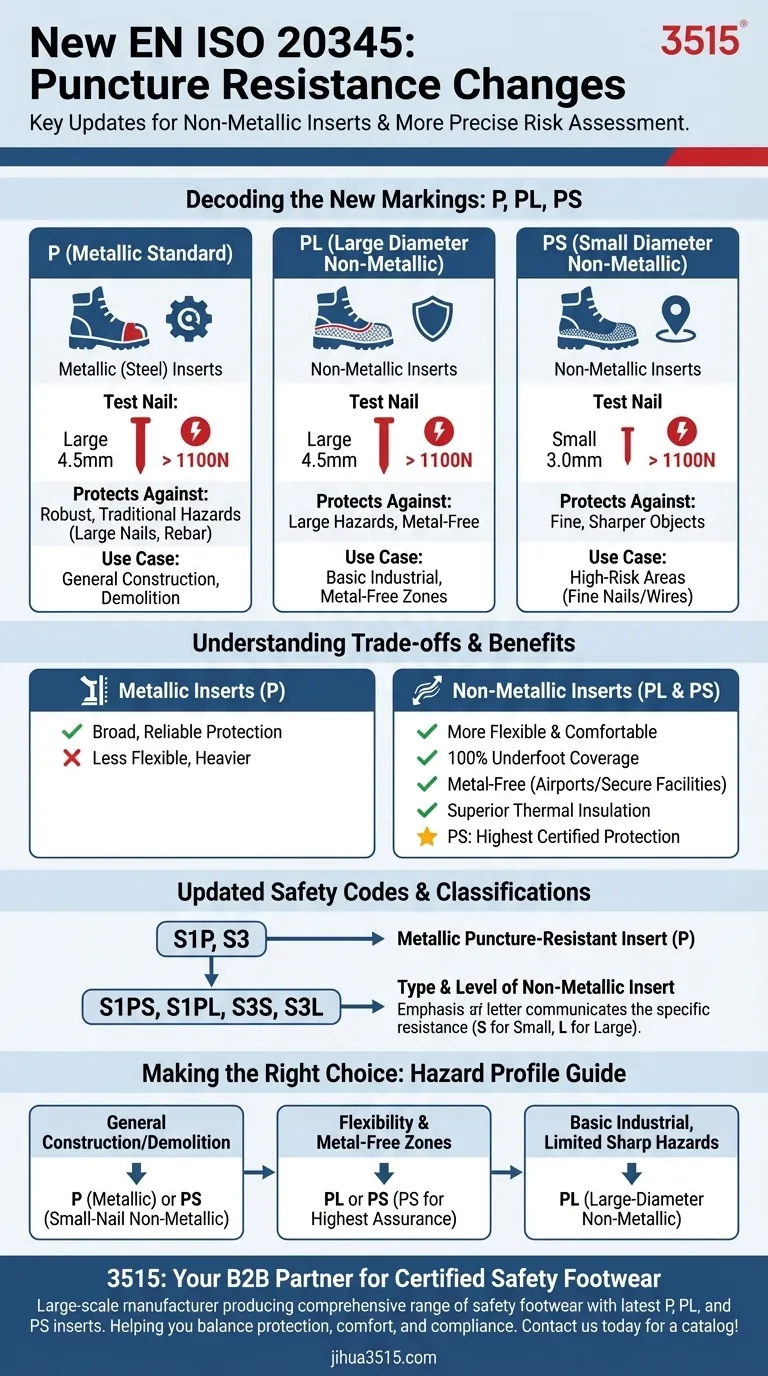

Decoding the New Puncture Resistance Markings

The core of the update lies in three distinct markings. All tests require the midsole to resist a perforation force of at least 1100 Newtons, but the object used for the test now varies.

P - The Metallic Standard

This marking is now reserved exclusively for metallic (steel) inserts. The test remains unchanged, using a 4.5mm diameter nail. This represents the traditional benchmark for robust, all-around puncture protection.

PL - Large Diameter Non-Metallic Protection

The "PL" marking indicates a non-metallic insert that has passed the test using the large 4.5mm diameter nail. This footwear provides protection against larger hazards like thick nails or rebar, offering the benefits of flexibility and being metal-free.

PS - Small Diameter Non-Metallic Protection

This is the most critical new category. The "PS" marking signifies a non-metallic insert that has passed a more stringent test using a small 3.0mm diameter nail. This rating provides a higher level of assurance against finer, sharper objects that pose a greater risk to fabric-based midsoles.

Understanding the Trade-offs

Choosing the right type of puncture resistance involves balancing protection levels with other functional needs. Each type of insert has distinct advantages.

Flexibility and Comfort

Non-metallic inserts (PL and PS) are significantly more flexible and lighter than their steel counterparts. They often cover 100% of the underfoot area, increasing overall comfort for workers who are on their feet all day.

Hazard Coverage

A "P" (metallic) insert offers broad, reliable protection. A "PS" (small nail) rated insert provides the highest certified level of protection for non-metallic options, specifically addressing the risk of fine, sharp objects. The "PL" insert meets the baseline standard for non-metallic protection against larger objects.

Environmental Demands

For work environments with metal detectors, such as airports or secure facilities, non-metallic "PL" or "PS" inserts are essential. They also provide superior thermal insulation in both hot and cold conditions.

How This Affects Footwear Classification

These new markings are integrated directly into the safety codes you see on the footwear itself, providing immediate clarity at the point of purchase.

Updated Safety Codes

The familiar S1P and S3 ratings will now exclusively signify that the footwear contains a metallic puncture-resistant insert.

The New Classifications

You will now see new codes such as S1PS, S1PL, S3S, or S3L. The final letter clearly communicates the type and level of non-metallic puncture resistance built into the shoe, removing any guesswork.

Making the Right Choice for Your Hazard Profile

Selecting the appropriate footwear requires a clear assessment of your most common workplace risks.

- If your primary focus is general construction or demolition: Seek footwear with a P (metallic) or PS (small-nail non-metallic) rating to ensure protection against the unpredictable risk of fine nails and sharp debris.

- If your primary focus is flexibility and metal-free environments: A PL or PS rated non-metallic insert is the ideal choice, with PS offering the highest level of certified puncture assurance.

- If your primary focus is basic industrial work with limited sharp-object hazards: Footwear with a PL rating provides certified non-metallic protection against common, larger-diameter puncture risks.

Ultimately, the updated EN ISO 20345 standard empowers you to make a more informed safety decision based on a precise understanding of your workplace risks.

Summary Table:

| Marking | Insert Type | Test Nail Diameter | Protection Level | Key Use Case |

|---|---|---|---|---|

| P | Metallic (Steel) | 4.5mm | Traditional, robust | General construction, demolition |

| PL | Non-Metallic | 4.5mm | Large diameter hazards | Basic industrial work, metal-free zones |

| PS | Non-Metallic | 3.0mm | Small, sharp objects | High-risk areas with fine nails/wires |

Ensure Your Team Has the Right Footwear for the Job

Navigating the new EN ISO 20345 standard is critical for workplace safety. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including models with the latest P, PL, and PS puncture-resistant inserts.

We can help you select the perfect footwear that balances protection, comfort, and compliance with your specific hazard profile.

Contact us today to discuss your safety footwear needs and request a catalog!

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why might steel toes be a valuable feature in motorcycle boots? Balancing Protection & Control

- What are the benefits of steel-toe boots in terms of impact resistance? Get Maximum Protection for Your Workforce

- What are the characteristics of steel toe boots? Maximum Protection & Key Trade-offs

- What industries are steel toe boots commonly used in? Essential Foot Protection for High-Risk Work

- What factors should be considered when choosing between steel and composite toe caps? Ensure Maximum Safety and Comfort