At its core, the choice between PVC and rubber boots is a direct trade-off between cost and performance. Your decision should be guided by your specific environment, the duration of wear, and how much physical stress the boots will endure.

Rubber is the superior choice for durability, flexibility, and comfort in demanding conditions, making it a long-term investment. PVC offers a lightweight, affordable, and often highly chemical-resistant alternative best suited for less frequent or less physically intensive use.

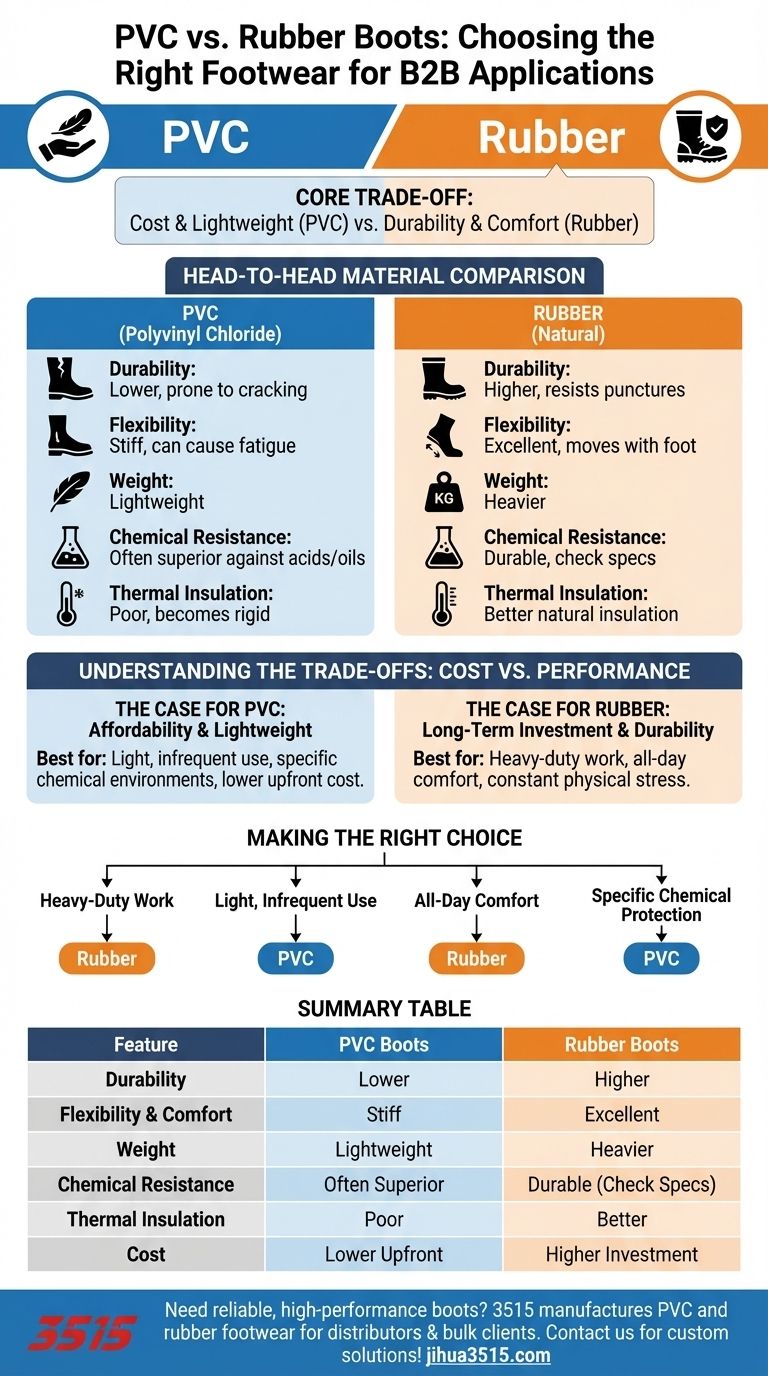

A Head-to-Head Material Comparison

Understanding the fundamental differences between these two materials is the first step in making an informed decision. They are not interchangeable, and each has distinct advantages in different scenarios.

Durability and Longevity

Natural rubber is inherently more robust and resistant to punctures, tears, and general wear. It can withstand repeated flexing without cracking, leading to a much longer lifespan under heavy use.

PVC (Polyvinyl Chloride) is a synthetic plastic that can become brittle over time, especially when exposed to cold temperatures or UV light. It is more susceptible to cracking at flex points.

Flexibility and Comfort

The natural elasticity of rubber allows it to move with your foot, providing significantly better comfort for walking, squatting, and climbing. This flexibility is crucial for reducing fatigue over long periods.

PVC is much stiffer. While this provides firm protection, its rigidity can lead to discomfort and chafing during extended wear, as it doesn't conform as well to your foot's movement.

Weight

This is a clear win for PVC. It is a substantially lighter material than rubber, which can be a significant advantage in reducing leg fatigue if you are wearing the boots all day but aren't engaged in high-flexibility tasks.

Chemical and Substance Resistance

Both materials provide excellent waterproof protection. However, PVC often has superior resistance to a wider range of chemicals, acids, oils, and fats. This makes it a preferred choice in specific industrial settings like food processing or chemical plants.

Rubber's resistance can vary by formulation, but it is generally very durable against common substances. Always check the manufacturer's specifications if chemical exposure is a primary concern.

Thermal Insulation

Rubber provides better natural insulation against the cold. In cold or freezing conditions, PVC not only offers less warmth but also becomes increasingly rigid and prone to cracking.

Understanding the Trade-offs: Cost vs. Performance

The most significant factor for many is the balance between the initial price and the boot's long-term value.

The Case for PVC: Affordability and Lightweight Protection

PVC boots are significantly less expensive to manufacture and purchase. If your primary need is basic, waterproof footwear for occasional tasks like gardening or washing a car, the lower cost and lighter weight of PVC make it a practical and economical choice.

The Case for Rubber: A Long-Term Investment in Durability

While rubber boots have a higher upfront cost, their superior durability means they often last much longer, providing better value over time for anyone who relies on them daily. If you work in agriculture, construction, or any demanding field, investing in rubber is investing in reliability.

The Hidden Cost of Stiffness

The primary drawback of PVC's lower cost is its rigidity. For anyone standing or walking for extended periods, the lack of flexibility can lead to significant discomfort and fatigue, which can ultimately impact productivity and well-being.

Making the Right Choice for Your Goal

Filter your decision through the lens of your primary activity.

- If your primary focus is heavy-duty work and long-term durability: Choose rubber for its superior resilience and ability to withstand constant physical stress.

- If your primary focus is affordability for light, infrequent use: Choose PVC for its low cost and effective basic waterproofing.

- If your primary focus is all-day comfort and flexibility: Choose rubber, as its natural elasticity significantly reduces fatigue.

- If your primary focus is protection from specific industrial chemicals or oils: Verify the specifications of PVC boots, as they often provide the best-in-class resistance.

Ultimately, aligning the material's inherent properties with your daily demands will ensure you get the protection and value you need.

Summary Table:

| Feature | PVC Boots | Rubber Boots |

|---|---|---|

| Durability | Lower; prone to cracking over time | Higher; resists punctures and tears |

| Flexibility & Comfort | Stiff; can cause fatigue | Excellent; moves with your foot |

| Weight | Lightweight | Heavier |

| Chemical Resistance | Often superior against acids/oils | Durable, but check specifications |

| Thermal Insulation | Poor; becomes rigid in cold | Better natural insulation |

| Cost | Lower upfront cost | Higher initial investment, better long-term value |

Need reliable, high-performance boots for your team or brand? As a large-scale manufacturer, 3515 produces a comprehensive range of PVC and rubber footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the right balance of durability, comfort, and cost-effectiveness for your specific needs. Contact us today to discuss custom solutions and bulk pricing!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What jobs are moc toe boots good for? Essential Footwear for Trades on Hard Surfaces

- What certification standard do all work boots meet? Your Guide to ASTM F2413 & Beyond

- What features are often included in welted work boots for comfort? A Guide to All-Day Support

- How long do work boots typically last? Maximize Lifespan & Safety

- What are the features of zip-up work boots? Unlock Speed, Safety, and Comfort

- What materials are used in comfortable Western-style work boots? Unlock All-Day Comfort & Durability

- What are the key features of firefighter work boots? Essential Protection & Support for First Responders

- What are some ASTM standards for work boots? A Guide to Certified Footwear Safety