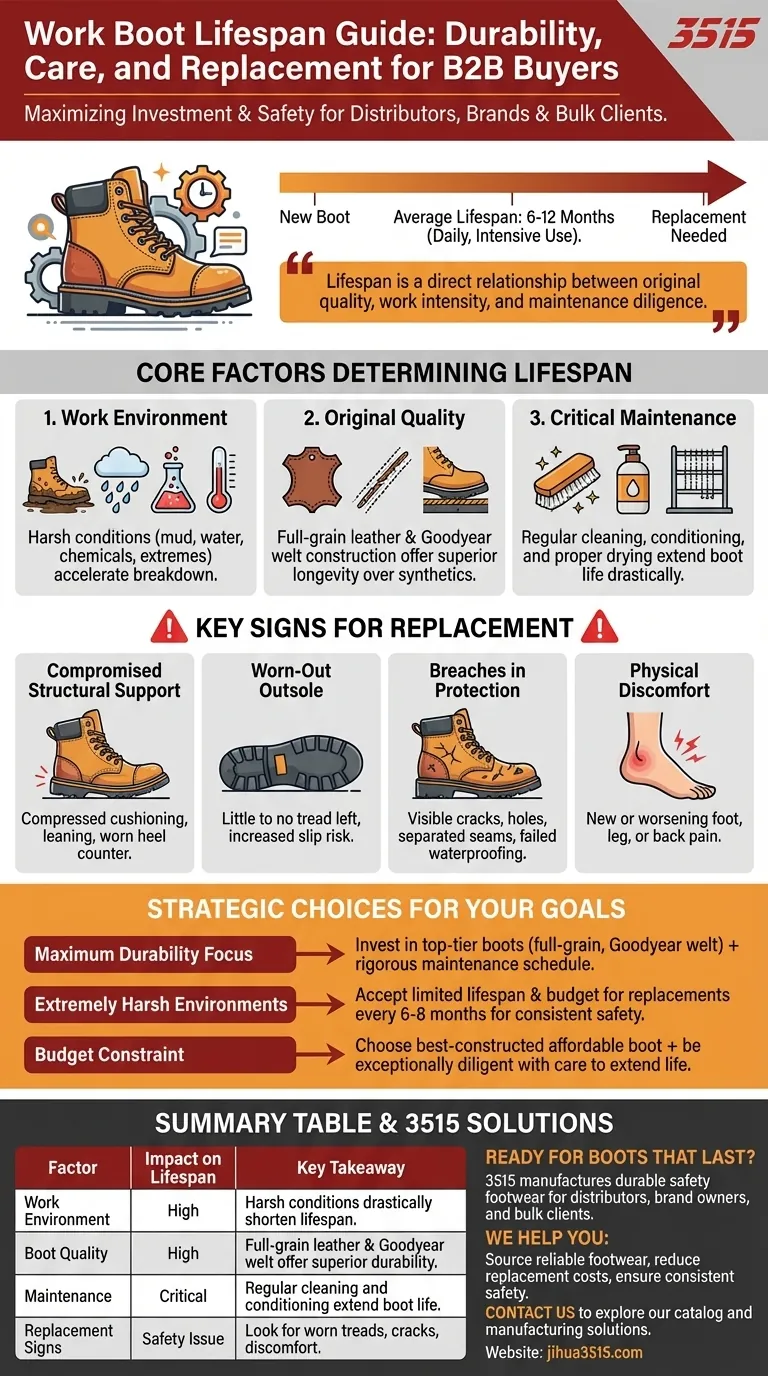

On average, a pair of work boots subjected to daily, intensive use will last between six and twelve months. This lifespan is not a guarantee but a general benchmark. The actual durability of your boots depends heavily on the quality of their construction, the harshness of your work environment, and how consistently you care for them.

The lifespan of your work boots is less about a fixed timeline and more about a direct relationship between the original quality of the boot, the intensity of your work, and the diligence of your maintenance routine.

The Core Factors That Determine Lifespan

Understanding what breaks a boot down is the first step to making it last. Several key variables are at play, each contributing significantly to the boot's rate of decay.

The Impact of Your Work Environment

The single biggest factor is how and where you use your boots. A boot worn daily on a construction site with exposure to mud, water, and abrasive surfaces will wear out much faster than one used in a clean, dry workshop.

Constant exposure to moisture, chemicals, or extreme temperatures will accelerate the breakdown of leather, adhesives, and stitching.

The Importance of Original Quality

Not all boots are created equal. The initial construction and materials dictate the boot's potential for longevity.

Higher-quality, full-grain leather boots will naturally outlast those made from cheaper synthetic materials. Likewise, the method of attaching the sole to the upper—such as a durable Goodyear welt versus a simple cement construction—makes a significant difference in durability and repairability.

The Critical Role of Maintenance

Proper care can dramatically extend the life of any boot, regardless of its initial quality. Neglect is a primary reason for premature failure.

Regularly cleaning off mud and debris prevents materials from breaking down. Conditioning the leather keeps it from drying out and cracking, while allowing boots to dry completely between wears prevents rot and bacterial growth.

Key Signs It's Time for a Replacement

Knowing when to retire your boots is a matter of safety, not just comfort. Continuing to use a worn-out pair can lead to slips, falls, and long-term foot, knee, or back problems.

Compromised Structural Support

The first thing to fail is often the internal support. Look for a compressed midsole that no longer provides cushioning, or a worn-down outsole with little to no tread left.

If the boot leans to one side when placed on a flat surface, the heel counter has likely failed, compromising ankle support.

Breaches in Protection

Your boots are a primary piece of safety equipment. Any visible cracks in the leather, holes, or separated seams mean the boot's protective barrier is compromised.

For waterproof boots, once the membrane fails, the boot will not only be uncomfortable but will also degrade much faster from constant moisture.

Physical Discomfort

Do not ignore pain. If you begin to experience new or worsening foot, leg, or back pain, your boots may no longer be providing the necessary support. This is a clear signal that it's time for a new pair.

Making the Right Choice for Your Goal

By aligning your purchase and maintenance habits with your specific needs, you can ensure you get the best possible value and protection.

- If your primary focus is maximum durability: Invest in a top-tier boot with full-grain leather and a Goodyear welt construction, and commit to a rigorous cleaning and conditioning schedule.

- If you work in extremely harsh, destructive environments: Accept that even the best boots have a limited lifespan and budget for replacements every 6-8 months to ensure consistent safety.

- If your budget is the main constraint: Choose the best-constructed boot you can afford and be exceptionally diligent with maintenance, as proper care is the most effective way to extend the life of a less-expensive boot.

Ultimately, viewing your work boots as a critical investment in your daily safety is the key to maximizing their value.

Summary Table:

| Factor | Impact on Lifespan | Key Takeaway |

|---|---|---|

| Work Environment | High | Harsh conditions (mud, chemicals) drastically shorten lifespan. |

| Boot Quality | High | Full-grain leather & Goodyear welt construction offer superior durability. |

| Maintenance | Critical | Regular cleaning and conditioning can significantly extend boot life. |

| Replacement Signs | Safety Issue | Look for compressed cushioning, worn treads, cracks, or discomfort. |

Ready for Work Boots That Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, built with the quality and construction methods that maximize longevity.

We help you:

- Source reliable footwear that stands up to demanding work environments.

- Reduce replacement costs for your customers or workforce with longer-lasting products.

- Ensure consistent safety with robust manufacturing standards.

Let's discuss your specific needs. Contact our team today to explore our catalog and manufacturing solutions.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What is the difference between a cowboy boot and a work boot? Choosing the Right Footwear for Your Task

- Why is rotating two pairs of work boots recommended? Double Boot Life & Boost Foot Health

- Why is it important to invest in a good pair of work boots? Maximize Safety & Save Money Long-Term

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety