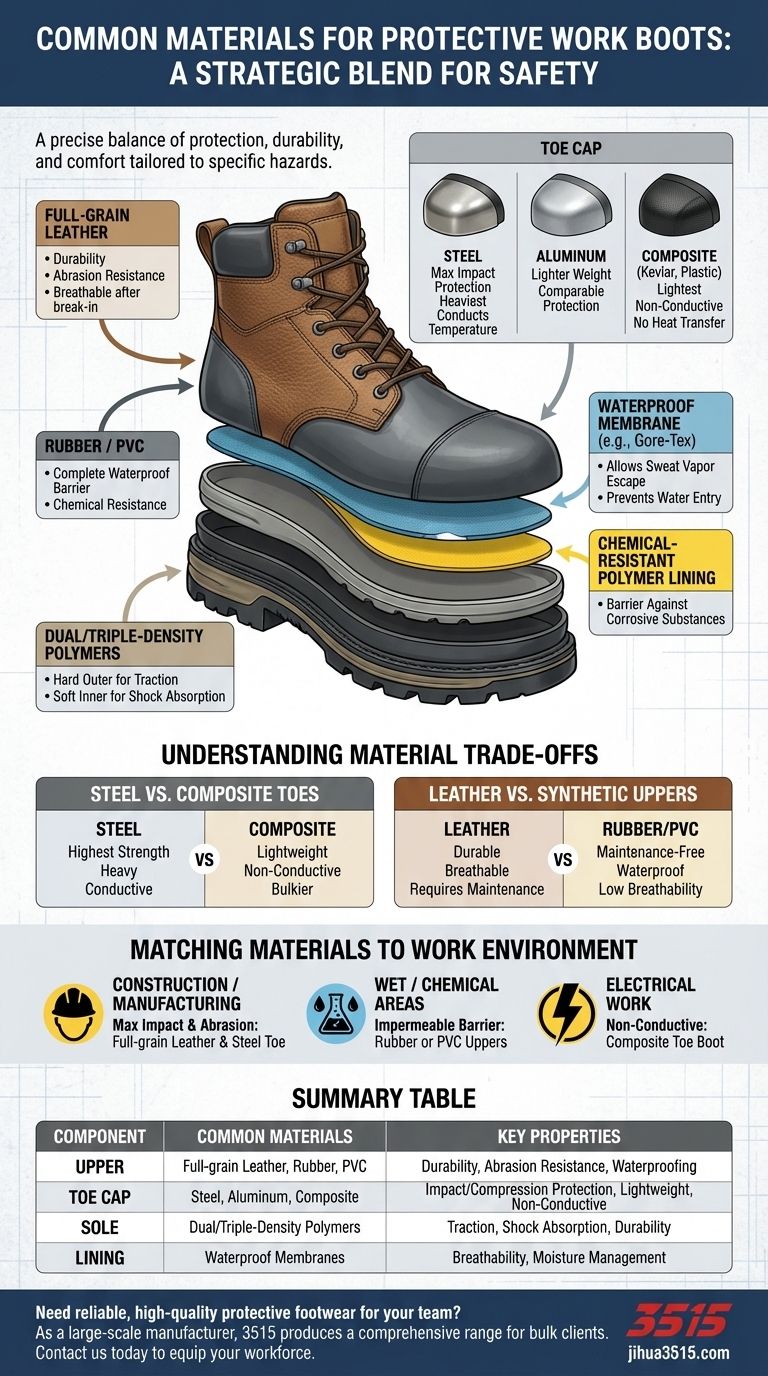

The most common materials for protective work boots are a strategic blend of traditional and advanced components, primarily full-grain leather, rubber, and PVC for the boot's body. These are supplemented with specialized materials like steel, aluminum, or composites for protective toe caps and advanced polymers for soles and linings.

The specific materials used in a work boot are not arbitrary; they are purposefully selected to provide a precise balance of protection, durability, and comfort tailored to the specific hazards of a given work environment.

Deconstructing the Modern Work Boot

A work boot is a system of specialized components, each made from materials chosen for a specific function. Understanding these parts reveals why material selection is so critical.

The Upper: The First Line of Defense

The upper is the main body of the boot that covers the foot. Its material dictates the boot's primary resistance to environmental factors.

Full-grain leather is a classic choice, prized for its exceptional durability and resistance to abrasion. It offers a high degree of comfort and breathability once broken in.

Rubber and Polyvinyl Chloride (PVC) are the materials of choice for environments with significant exposure to water, mud, or chemicals. These synthetic materials create a completely waterproof barrier.

The Protective Toe Cap: Guarding Against Impact

The safety toe is the boot's most recognized safety feature, designed to protect against compression and impact injuries.

Steel is the traditional standard, offering the maximum level of protection against impact. It is the heaviest and most robust option available.

Aluminum offers a lighter-weight alternative to steel while still meeting safety standards. It provides comparable protection with less bulk.

Composite materials, such as Kevlar, carbon fiber, or specialized plastics, are the lightest options. A key advantage is that they do not conduct electricity or heat, making them ideal for certain environments.

The Sole: Foundation of Safety and Comfort

The outsole provides traction and protects you from what's underfoot, while the midsole provides cushioning and support.

Modern boots often feature dual or triple-density soles. These combine different polymers to create a sole that is hard and durable on the outside for grip but softer on the inside for shock absorption.

Linings and Membranes: Managing the Environment

Interior materials are crucial for comfort and protection from moisture or specific hazards.

Waterproof membranes, like Gore-Tex, are often laminated to the boot's lining. These allow sweat vapor to escape while preventing water from getting in, keeping feet dry and comfortable.

Specialized chemical-resistant polymers are used in boots designed for environments with hazardous materials, providing a necessary barrier against corrosive substances.

Understanding the Material Trade-offs

Choosing the right work boot involves balancing competing factors. No single material is perfect for every situation.

Steel vs. Composite Toes

The primary trade-off is between maximum protection and functionality. Steel toes offer the highest strength but are heavy and conduct temperature. Composite toes are lighter, don't conduct electricity or temperature, but can be slightly bulkier to achieve the same safety rating.

Leather vs. Synthetic Uppers

The choice here balances breathability against impermeability. Leather is highly durable and breathable but requires maintenance to remain water-resistant. Rubber and PVC offer superior, maintenance-free waterproofing but provide very little breathability.

The Importance of Purpose-Built Design

Materials are selected based on the needs of specific industries. A boot for a construction worker facing abrasion and impact hazards will be built differently than one for a food processing worker who needs chemical resistance and slip-proof soles.

Matching Materials to Your Work Environment

Your choice of boot should be dictated entirely by the demands and potential hazards of your job.

- If your primary focus is construction or manufacturing: You need maximum impact protection and abrasion resistance, making full-grain leather uppers with a steel toe the standard choice.

- If your primary focus is working in wet or chemical-heavy areas: You need an impermeable barrier, making boots with rubber or PVC uppers essential.

- If your primary focus is electrical work or requires passing through metal detectors: You need non-conductive, non-metallic protection, making a composite toe boot the only logical option.

Ultimately, the right materials ensure your footwear is not just a uniform requirement but an active tool for your safety.

Summary Table:

| Component | Common Materials | Key Properties |

|---|---|---|

| Upper | Full-grain Leather, Rubber, PVC | Durability, Abrasion Resistance, Waterproofing |

| Toe Cap | Steel, Aluminum, Composite (Kevlar, Plastic) | Impact/Compression Protection, Lightweight, Non-Conductive |

| Sole | Dual/Triple-Density Polymers | Traction, Shock Absorption, Durability |

| Lining | Waterproof Membranes (e.g., Gore-Tex) | Breathability, Moisture Management |

Need reliable, high-quality protective footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and work footwear for distributors, brand owners, and bulk clients. Our expertise ensures the perfect blend of materials—from durable leather uppers to advanced composite toes—is used to meet the specific safety and comfort demands of your industry.

Contact us today for a consultation and discover how we can equip your workforce with boots built for protection and performance.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

People Also Ask

- How often should cowboy boots undergo routine cleaning and conditioning? A 3-6 Month Guide to Longevity

- What are the key considerations when choosing work boots? Prioritize Safety, Durability, and Comfort

- What features should construction and industrial work boots have? Essential Safety & Protection Guide

- What customization options are available for moc toe boots? Build the Perfect Boot for Your Needs

- What precautions should be taken when drying work boots? Avoid High Heat to Protect Your Investment

- What alternative solutions exist for protecting leather boots during hazmat responses? Preserve Your Gear & Budget

- What are the characteristics of premium quality leather used in men's boots? Durability, Flexibility & Timeless Style

- How to choose the right work boot? Match Safety Features to Your Job's Hazards