The single biggest factor in a light work boot’s midsole construction is the choice of material. To achieve lightness, manufacturers primarily rely on a specialized foam compound called Ethylene-vinyl acetate, or EVA. This material is inherently light due to its structure, providing significant cushioning and shock absorption without the density and weight of traditional materials like solid rubber or polyurethane.

The core principle behind a lightweight midsole is a trade-off: manufacturers sacrifice some long-term durability and compression resistance in exchange for a significant reduction in weight and an increase in initial comfort by using materials like EVA foam.

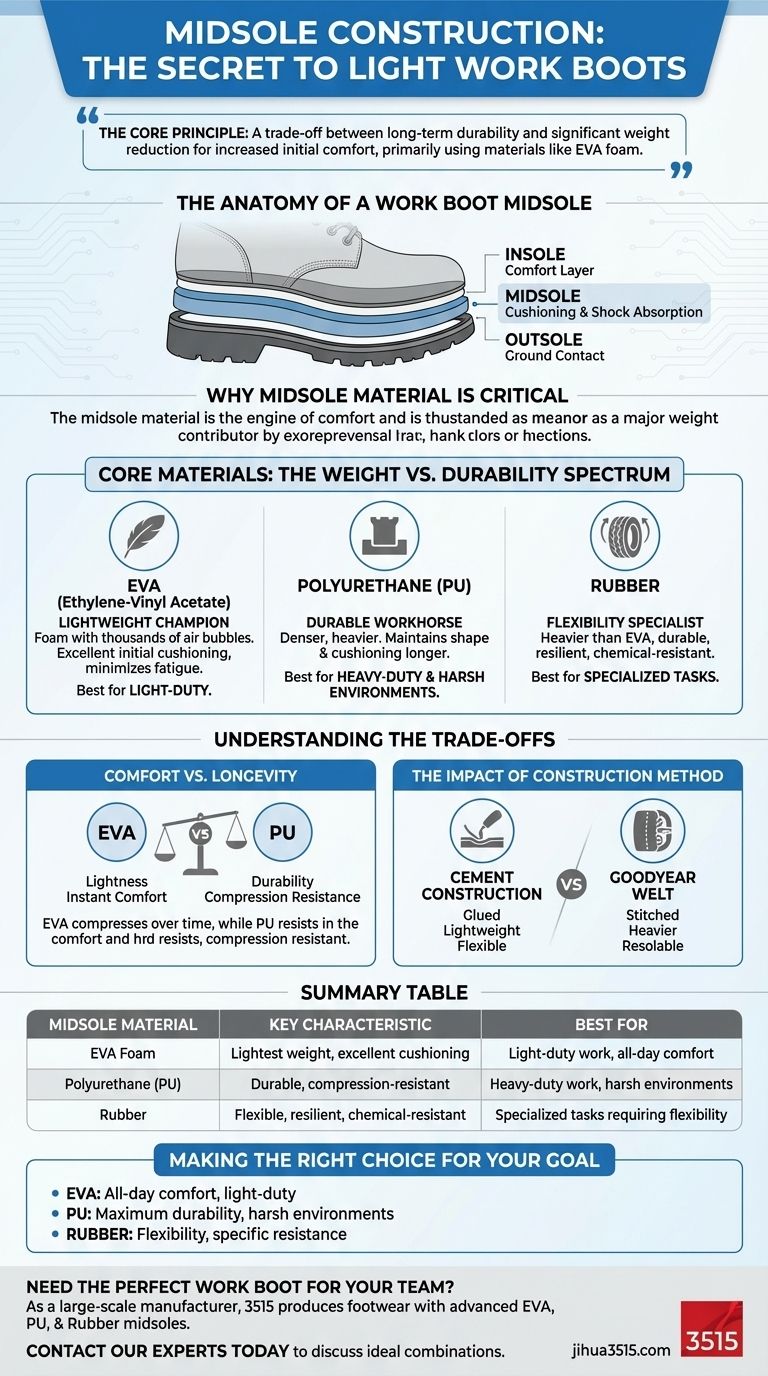

The Anatomy of a Work Boot Midsole

What is the Midsole?

The midsole is the critical layer sandwiched between the insole (what your foot rests on) and the outsole (what contacts the ground). Its primary jobs are to provide cushioning, absorb shock from impacts, and offer stability during movement.

Why Midsole Material is Critical

This layer is the engine of the boot's comfort and a major contributor to its overall weight. A dense, heavy midsole will result in a heavy, fatiguing boot, regardless of how light the upper materials are. The material choice here defines the boot's character.

Core Materials: The Weight vs. Durability Spectrum

Ethylene-Vinyl Acetate (EVA): The Lightweight Champion

EVA is a foam polymer filled with thousands of tiny air bubbles. This composition makes it exceptionally lightweight and provides excellent initial cushioning, much like the material used in modern running shoes.

This is the go-to choice for boots where minimizing weight and reducing wearer fatigue are the top priorities.

Polyurethane (PU): The Durable Workhorse

Polyurethane (PU) is a denser, heavier polymer. While it adds more weight to the boot, it is significantly more durable and resistant to compression than EVA.

A PU midsole will maintain its shape and cushioning properties for much longer, making it ideal for heavy-duty work and harsh environments.

Rubber: The Flexibility Specialist

While less common as a standalone midsole in light boots, rubber is sometimes used for its flexibility and resilience. It is heavier than EVA but can offer a unique combination of durability and ground feel.

Understanding the Trade-offs

Comfort vs. Longevity

The primary trade-off is between immediate comfort and long-term durability. An EVA midsole feels comfortable and light out of the box but will compress and "pack out" over time, losing its cushioning ability. A PU midsole, while heavier, will resist this compression far more effectively.

The Impact of Construction Method

The method used to attach the sole to the boot also plays a role. Cement Construction, where the sole is glued to the upper, is a lightweight and flexible method perfectly suited for EVA midsoles.

In contrast, a traditional Goodyear Welt Construction is heavier and more rigid but allows for resoling. This robust method is more often paired with durable PU or rubber midsoles.

Making the Right Choice for Your Goal

To select the right boot, you must align the midsole material with the demands of your job.

- If your primary focus is all-day comfort and minimizing fatigue for light-duty work: Choose a boot with an EVA midsole for its superior lightness and cushioning.

- If your primary focus is maximum durability and support in a harsh environment: A Polyurethane (PU) midsole is the superior choice for its resistance to wear and compression.

- If your primary focus is flexibility and resistance to specific chemicals or oils: Look for boots specifying rubber midsoles or outsoles, as they often have specialized properties.

Understanding the midsole empowers you to choose a boot based on its engineered performance, not just its appearance.

Summary Table:

| Midsole Material | Key Characteristic | Best For |

|---|---|---|

| EVA Foam | Lightest weight, excellent cushioning | Light-duty work, all-day comfort |

| Polyurethane (PU) | Durable, compression-resistant | Heavy-duty work, harsh environments |

| Rubber | Flexible, resilient, chemical-resistant | Specialized tasks requiring flexibility |

Need the perfect work boot for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including models with advanced EVA, PU, and rubber midsoles tailored to your specific job requirements.

Contact our experts today to discuss how we can deliver the ideal combination of comfort, durability, and value for your customers.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why are synthetic materials unsuitable for wildland fire boots? They Melt Under Extreme Heat

- What materials and craftsmanship define quality Western work boots? | Built for Durability & Safety

- How to select the right work boots? Match Your Profession's Hazards for Optimal Safety & Comfort

- What are the requirements for compression resistance in safety toe boots? Ensure OSHA & ASTM F2413 Compliance

- What are the common types of toe protection in work boots? Choose the Right Safety Toe for Your Job

- What materials provide comfort in construction boots? Unlock All-Day Comfort for Your Workforce

- How do industrial-grade protective boots assist new employees? Ensure Stability and Safety During Career Transitions

- How do the heels differ between cowboy boots and Western work boots? Choose the Right Heel for Your Job