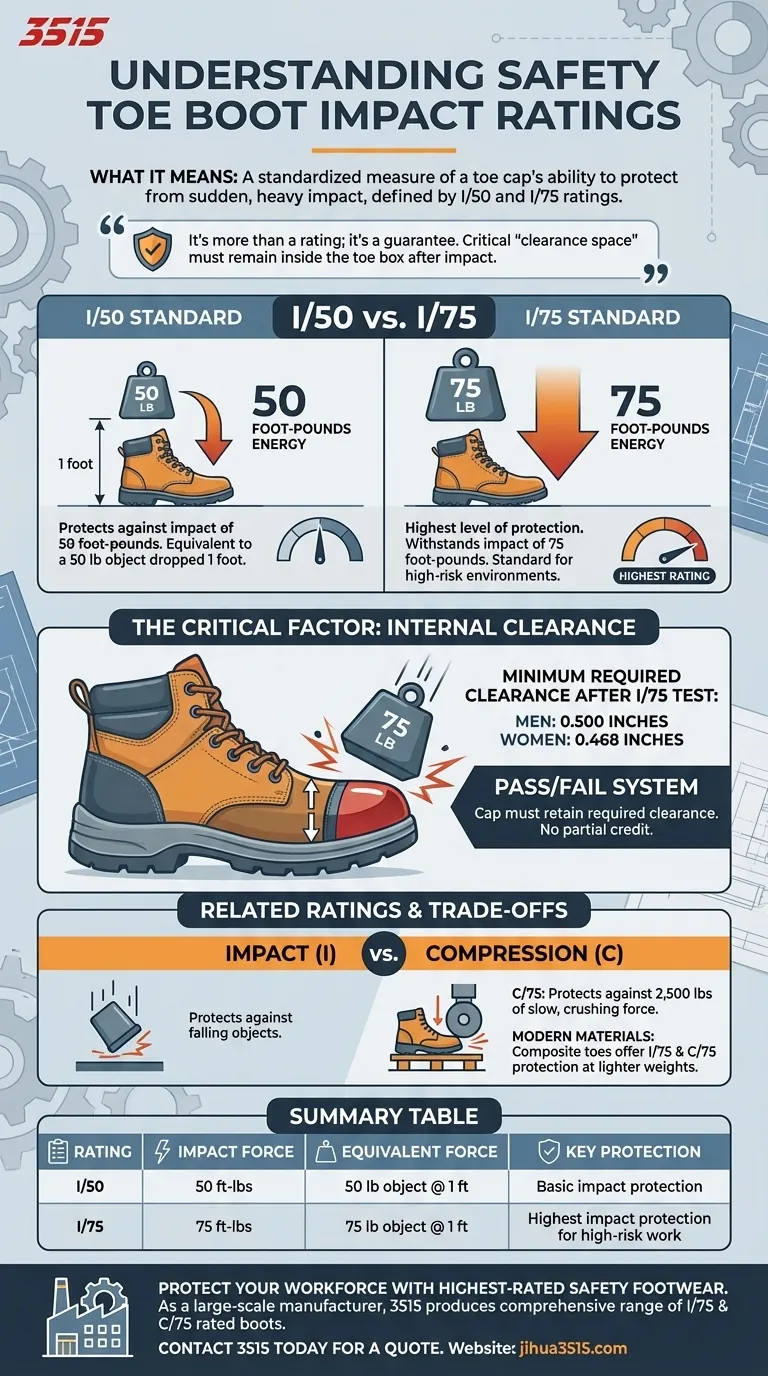

The impact rating on a safety boot is a standardized measure of its toe cap's ability to protect your feet from a sudden, heavy impact. It is defined by two primary levels, I/50 and I/75, which directly correspond to the amount of force, measured in foot-pounds, that the boot can withstand while still preventing injury. The I/75 rating represents the highest level of impact protection available under current safety standards.

The number on your boot's safety tag is more than just a rating; it's a guarantee. It certifies that after a specific, powerful impact, a critical amount of "clearance space" will remain inside the toe box, which is the true measure of whether your toes are protected from being crushed.

Decoding the Impact Rating: I/50 vs. I/75

To select the right boot, you first need to understand what the numbers mean in a practical sense. The rating system is based on a straightforward physics principle.

What is a "Foot-Pound"?

A foot-pound is a unit of energy. One foot-pound is the energy required to lift a one-pound object one foot high. The impact rating test simulates this by dropping a weighted object from a set height onto the boot's toe.

The I/50 Standard

An I/50-rated boot is tested to protect your foot from an impact of 50 foot-pounds. This is equivalent to a 50-pound object being dropped from a height of one foot.

The I/75 Standard

An I/75-rated boot provides a higher level of protection, tested to withstand an impact of 75 foot-pounds. This is the highest rating for impact resistance and is standard for work in construction, manufacturing, and other high-risk environments.

The Critical Factor: Internal Clearance

Simply stopping a heavy object is not enough. The true test of a safety toe is its ability to maintain its shape under force, ensuring there is enough room left inside to keep your toes from being crushed.

Why Clearance is the Real Test

The goal of the protective toe cap is to prevent the force of the impact from being transferred to your foot. If the cap deforms too much, it can cause the very injury it's designed to prevent.

The ASTM Standard for Clearance

Safety standards mandate a minimum clearance that must be maintained inside the toe cap after the impact test. For a boot to pass the I/75 test, it must retain:

- 0.500 inches of space for men's footwear.

- 0.468 inches of space for women's footwear.

A Simple Pass/Fail System

A boot either meets the standard or it fails. There is no partial credit. If the toe cap retains the required clearance after a 75 foot-pound impact, it earns the I/75 rating. If it doesn't, it cannot be certified at that level.

Understanding the Trade-offs and Related Ratings

Impact is only one type of hazard. A comprehensive safety boot also protects against compression, which is a different kind of force.

Impact vs. Compression (C/75)

While the Impact (I) rating protects against falling objects, the Compression (C) rating protects against crushing forces from rolling or static objects, like a vehicle tire or a heavy pallet.

The highest compression rating, C/75, certifies that the boot will maintain the same critical clearance space while being subjected to 2,500 pounds of slow, crushing force. Most high-quality boots will carry both an I/75 and C/75 rating.

Do Higher Ratings Mean Heavier Boots?

Historically, a higher rating meant a heavier steel toe. However, modern composite toe materials can often provide the same I/75 and C/75 protection at a significantly lower weight, improving comfort without sacrificing safety.

Making the Right Choice for Your Work

Choosing the correct rating is a critical decision based on the specific hazards of your environment.

- If your primary focus is maximum safety in high-risk environments: Always select a boot with both I/75 and C/75 ratings, as this offers the highest certified protection against both impact and compression.

- If your work involves lighter duties but still requires foot protection: While an I/50-rated boot may meet minimum requirements, the I/75 rating provides a superior safety margin for what is often a negligible difference in cost or weight.

- If you are ever unsure about your workplace requirements: Default to the highest rating (I/75). It is always better to have more protection than you might need.

Understanding these ratings empowers you to move beyond simple compliance and make an active choice for your personal safety on the job.

Summary Table:

| Rating | Impact Force (Foot-Pounds) | Equivalent Force | Key Protection |

|---|---|---|---|

| I/50 | 50 ft-lbs | 50 lb object dropped 1 foot | Basic impact protection |

| I/75 | 75 ft-lbs | 75 lb object dropped 1 foot | Highest impact protection for high-risk work |

Protect your workforce with the highest-rated safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of I/75 and C/75 rated safety boots and shoes for distributors, brand owners, and bulk clients. Our expertise ensures your team gets durable, comfortable, and fully certified footwear tailored to your industry's hazards.

Contact 3515 today to discuss your safety footwear needs and request a quote.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the consequences of not wearing safety shoes? Protect Your Feet from Severe Workplace Injuries

- Are steel toe boots inherently bad for your feet? Debunking Myths for Workplace Safety

- What types of safety toe boots are available? Find the Perfect Fit for Your Job's Hazards

- How can one prevent blisters when wearing steel toe boots? A Complete Guide to Pain-Free Workdays

- What types of safety toe boots are available for different job requirements? Choose the Right Protection for Your Work