Beyond a simple "oil-resistant" label, safety boots are available in a vast range of specialized designs tailored to specific hazards, industries, and fit preferences. Key designs include rugged construction boots with steel toes, anti-slip models for the food industry, pull-on or lace-up styles for convenience, and ankle-height boots for mobility. Each design combines oil resistance with other critical safety features to create a purpose-built tool for the job.

The most important factor is not simply finding a boot that resists oil, but selecting a design where oil resistance is combined with the correct sole material, toe protection, and specialized features required by your specific work environment.

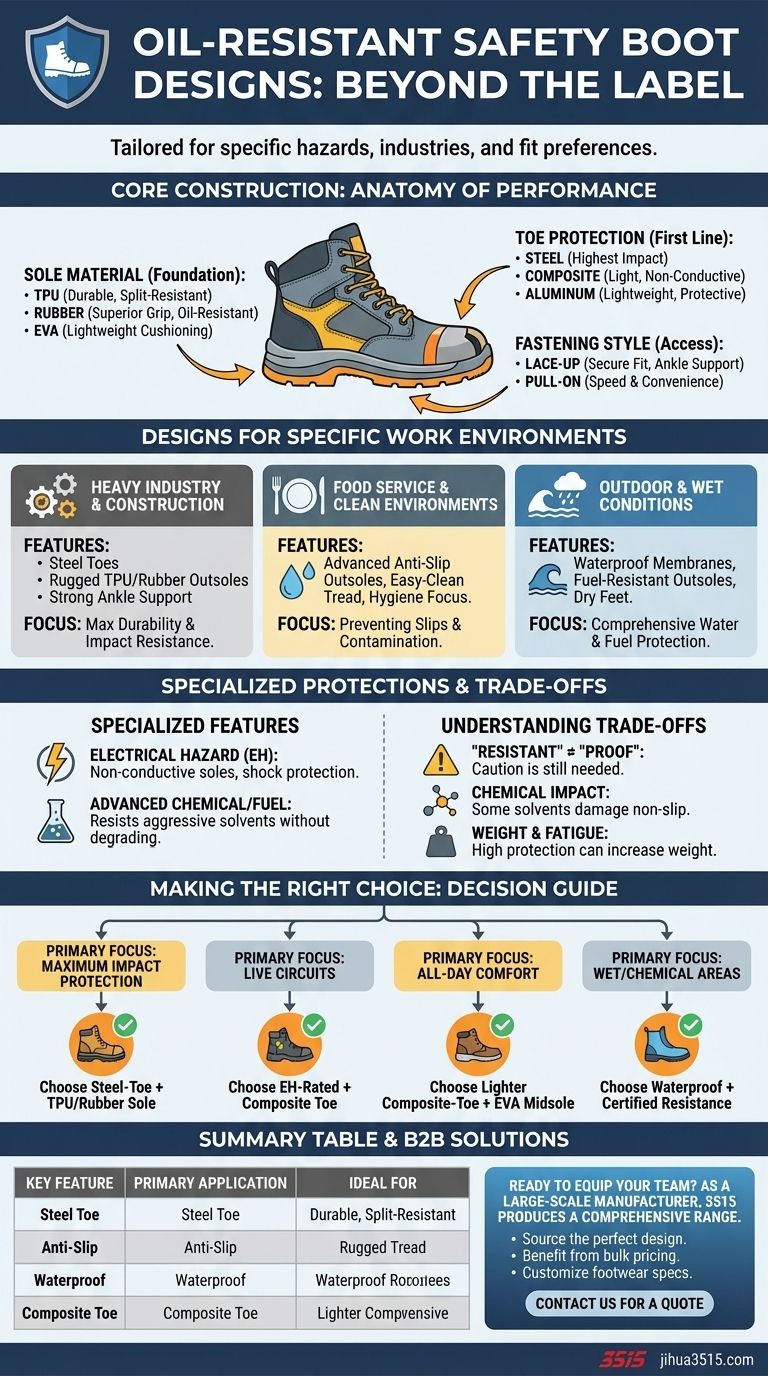

Core Construction: The Anatomy of a Safety Boot

Understanding the fundamental components of an oil-resistant boot is the first step in making an informed choice. The sole, toe, and fastening method form the foundation of its performance and safety profile.

Sole Material: The Foundation of Resistance

The outsole is your primary point of contact with hazardous surfaces. Thermo-polyurethane (TPU) is valued for its exceptional durability and resistance to splitting. Rubber outsoles provide superior grip and oil resistance. Ethylene-vinyl acetate (EVA) is often used in the midsole for its lightweight cushioning and comfort.

Toe Protection: The First Line of Defense

The type of toe cap dictates impact protection and weight. Steel toes offer the highest level of protection against impact and compression. Composite toes are lighter, do not conduct electricity or temperature, and are ideal for environments with metal detectors. Aluminum toes provide a lightweight alternative to steel but with similar protective qualities.

Fastening Style: Access and Fit

The choice between fastening styles often comes down to a balance of convenience and support. Lace-up boots provide a secure, adjustable fit and superior ankle support. Pull-on styles offer speed and convenience, making them ideal for environments where you need to put on or remove boots frequently.

Designs for Specific Work Environments

Oil resistance is a baseline feature. The true value comes from how that feature is integrated into a boot designed for a particular application.

For Heavy Industry and Construction

Boots for these environments prioritize maximum durability and impact resistance. They typically feature steel toes, rugged TPU or rubber outsoles for puncture resistance, and strong ankle support to prevent injuries on uneven terrain.

For Food Service and Clean Environments

In these settings, preventing slips is paramount. Designs focus on advanced anti-slip outsoles with tread patterns engineered to channel away liquids. They are also often designed for easy cleaning to maintain hygiene standards.

For Outdoor and Wet Conditions

For those working on docks, offshore rigs, or in mining, water is as much a hazard as oil. These boots incorporate waterproof membranes and materials to keep feet dry, often combined with fuel-resistant outsoles for comprehensive protection.

Specialized Protective Features

For high-risk jobs, you need boots with certified protections against specific, less-common hazards. Always look for clear labeling that indicates these special ratings.

Electrical Hazard (EH) Protection

EH-rated boots are constructed with non-conductive, shock-resistant soles and heels. This feature provides a secondary source of protection against accidental contact with live electrical circuits.

Advanced Chemical and Fuel Resistance

While all boots in this category resist oil, some environments involve more aggressive solvents, fuels, or chemicals. Specialized boots use advanced elastomers and construction techniques to withstand these substances without degrading.

Understanding the Trade-offs and Limitations

No piece of safety equipment is infallible. Acknowledging the limitations of oil-resistant boots is critical for maintaining safety.

"Resistant" Does Not Mean "Proof"

An oil-resistant sole significantly improves grip on oily surfaces, but it cannot guarantee against slips in cases of large spills or extremely slick conditions. Always proceed with caution.

The Impact of Other Chemicals

The boot's non-slip surface can be permanently damaged by certain solvents or aggressive chemicals. Ensure your boot's resistance profile matches all the substances you may encounter.

Protection Can Come at a Cost

Features like steel toes and thick, puncture-resistant soles offer incredible protection but add weight and rigidity. This can lead to fatigue over a long workday compared to lighter composite-toe options.

Making the Right Choice for Your Goal

Select your footwear based on a clear-eyed assessment of your primary daily risks.

- If your primary focus is maximum impact protection: Choose a steel-toe boot with a durable and puncture-resistant rubber or TPU sole.

- If your primary focus is working around live circuits: Insist on a boot with a clearly marked Electrical Hazard (EH) rating and a composite toe.

- If your primary focus is all-day comfort and mobility: Consider a lighter composite-toe boot with a cushioned EVA midsole.

- If your primary focus is working in wet or chemical-heavy areas: Select a waterproof design with certified resistance to the specific fuels or chemicals present.

Ultimately, choosing the right safety boot is an investment in your personal protective equipment, ensuring you have the right tool for the job.

Summary Table:

| Key Design Feature | Primary Application | Ideal For |

|---|---|---|

| Steel Toe, TPU/Rubber Sole | Heavy Industry & Construction | Maximum impact and puncture protection |

| Anti-Slip Sole, Easy-Clean | Food Service & Clean Rooms | Superior slip resistance and hygiene |

| Waterproof, Fuel-Resistant | Outdoor & Wet Conditions | Protection from water, oil, and chemicals |

| Composite Toe, EH Rating | Electrical Work Environments | Lightweight protection and shock resistance |

Ready to equip your team with the right safety boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of oil-resistant and specialized safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the specific demands of your industry and workforce.

We can help you:

- Source the perfect design for your specific work environment and hazards.

- Benefit from bulk pricing and reliable supply chain logistics.

- Customize footwear to meet your brand's unique specifications.

Contact us today to discuss your requirements and get a quote: Get in Touch

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- Why are safety shoes considered a core identification target in industrial monitoring? Boosting AI Compliance

- What are the advantages of water-based polyurethane spray coatings for safety shoe slip resistance? Enhanced Traction

- What does OSHA 1910.136 state about safety footwear? A Guide to Compliance & Selection

- Why are functional socks made of moisture-wicking materials essential? Boost Comfort in Occupational Protective Footwear

- Are composite toe boots airport friendly? Yes, Avoid Security Delays with Non-Metallic Toes

- Why is the hardware implementation of defense and shielding functions emphasized in industrial safety? Unlocking Safety

- What role do anti-smash toe caps play in safety footwear? Essential Protection for Metal Manufacturing

- What additional specifications should be considered when choosing safety toe boots? Match Your Boot to Your Job's Hazards