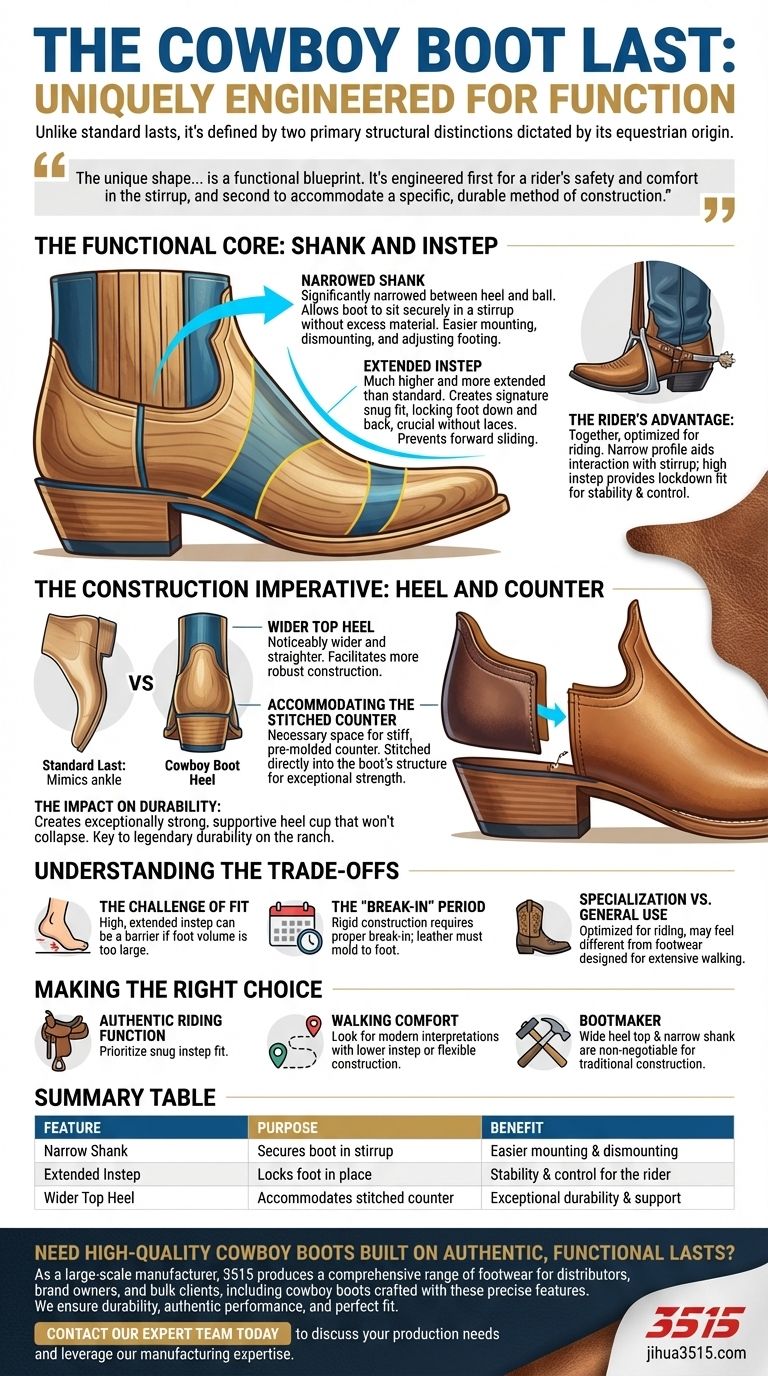

Unlike standard footwear lasts, a cowboy boot last is defined by two primary structural distinctions: an extended instep created by a very narrow shank and a wider, less-curved top heel. These features are not merely stylistic; they are direct results of the boot's original function as equestrian equipment and dictate its unique construction process.

The unique shape of a cowboy boot last—specifically its narrow shank and wide heel top—is a functional blueprint. It’s engineered first for a rider's safety and comfort in the stirrup, and second to accommodate a specific, durable method of construction.

The Functional Core: Shank and Instep

The most significant modifications to a cowboy boot last are centered around the middle of the foot, directly influencing its fit and performance in a stirrup.

The Narrowed Shank

The shank is the area of the last between the heel and the ball of the foot. On a cowboy boot last, this area is significantly narrowed.

This design allows the boot to sit securely in a stirrup without excess material getting in the way, making it easier for a rider to mount, dismount, and adjust their footing.

The Extended Instep

The narrow shank directly results in a much higher and more extended instep compared to a standard shoe or boot last.

This high arch creates the signature snug fit of a cowboy boot, locking the wearer's foot down and back into the heel. Without laces for adjustment, this tight instep is critical for preventing the foot from sliding forward.

The Rider's Advantage

Together, these features create a tool optimized for riding. The narrow profile aids interaction with the stirrup, while the high instep provides the lockdown fit needed for stability and control in the saddle.

The Construction Imperative: Heel and Counter

The second major distinction lies in the shape of the heel, which is dictated by a specific, traditional method of bootmaking.

A Wider Top Heel

A standard last curves inward sharply at the top of the heel to mimic the shape of the human ankle. A cowboy boot last is noticeably wider and straighter in this area.

This less-contoured shape is a deliberate choice to facilitate a more robust construction technique.

Accommodating the Stitched Counter

The wider heel is necessary to make room for a very stiff, pre-molded heel counter, often made of thick, oak-tanned leather.

Unlike in most footwear where a flexible counter is "slipped" over the last, this rigid counter is placed against the last and stitched directly into the boot's structure. The wider last shape provides the necessary space for this assembly.

The Impact on Durability

This method creates an exceptionally strong and supportive heel cup that will not collapse over time. It’s a key element of the boot's legendary durability, designed to withstand the rigors of life on a ranch.

Understanding the Trade-offs

The specialized nature of the cowboy boot last introduces unique challenges regarding fit and comfort.

The Challenge of Fit

The high, extended instep is the primary barrier to entry for many wearers. If your foot's instep volume is larger than what the last was designed for, you simply will not be able to get the boot on.

The "Break-in" Period

The rigid construction enabled by the last's shape—especially the stiff, stitched-in counter—means that a proper break-in period is often required. The leather must mold to the wearer's foot, which can take time.

Specialization vs. General Use

A last designed perfectly for stirrup stability is not always ideal for extensive walking. The rigid shank and pitched heel are optimized for riding, which can feel different from footwear designed specifically for a walking gait.

Making the Right Choice for Your Goal

Understanding the last's design helps you interpret the fit and function of a cowboy boot.

- If your primary focus is authentic riding function: Prioritize a snug fit across the instep, as this proves the boot is built on a traditional last designed to hold your foot securely.

- If your primary focus is walking comfort: Look for modern interpretations that may use a last with a slightly lower instep or more flexible construction, even if it deviates from the traditional equestrian design.

- If you are a bootmaker: Recognize that the wide heel top and narrow shank are non-negotiable for traditional construction and will dictate your pattern-making for the counter.

Ultimately, the cowboy boot last is a masterclass in how a specific function can create a timeless and iconic form.

Summary Table:

| Feature | Purpose | Benefit |

|---|---|---|

| Narrow Shank | Secures boot in stirrup | Easier mounting & dismounting |

| Extended Instep | Locks foot in place | Stability & control for the rider |

| Wider Top Heel | Accommodates stitched counter | Exceptional durability & support |

Need high-quality cowboy boots built on authentic, functional lasts?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including cowboy boots crafted with the precise structural features detailed above. We ensure durability, authentic performance, and a perfect fit for your customers.

Contact our expert team today to discuss your production needs and leverage our manufacturing expertise.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the potential drawbacks of Goretex-lined boots? The Hidden Trade-Offs of Waterproof Footwear

- What are the characteristics of synthetic walking boots? Modern Comfort Meets Trail-Ready Durability

- What is a CAM walker or walking boot? A Guide to Healing with Mobility

- Why are socks important for walking footwear? The Key to Blister-Free Comfort

- What type of winter boots are suitable for city or town use? Find the Perfect Urban Winter Boots

- Why is the lining of cowboy boots important? The Secret to All-Day Comfort & Durability

- What are the key characteristics of the Clarks Desert Boot? Unmatched Comfort & Timeless Style

- What type of cushioning should walking shoes have? Find the Perfect Balance of Comfort & Stability