While essential for impact protection, steel toe boots introduce a distinct set of risks that go far beyond the worksite hazard they are designed to prevent. The primary dangers are not from the failure of the steel cap but from the cumulative, daily effects of their weight, rigidity, and material properties. These risks manifest as musculoskeletal strain, chronic foot conditions, and environmental hazards like extreme cold transfer and electrical conductivity.

The greatest risk of steel toe boots is not a catastrophic accident, but the slow, cumulative damage caused by forcing your feet into a heavy, rigid, and often ill-fitting environment. Mitigating this risk depends entirely on prioritizing a precise fit and understanding the inherent trade-offs of the materials.

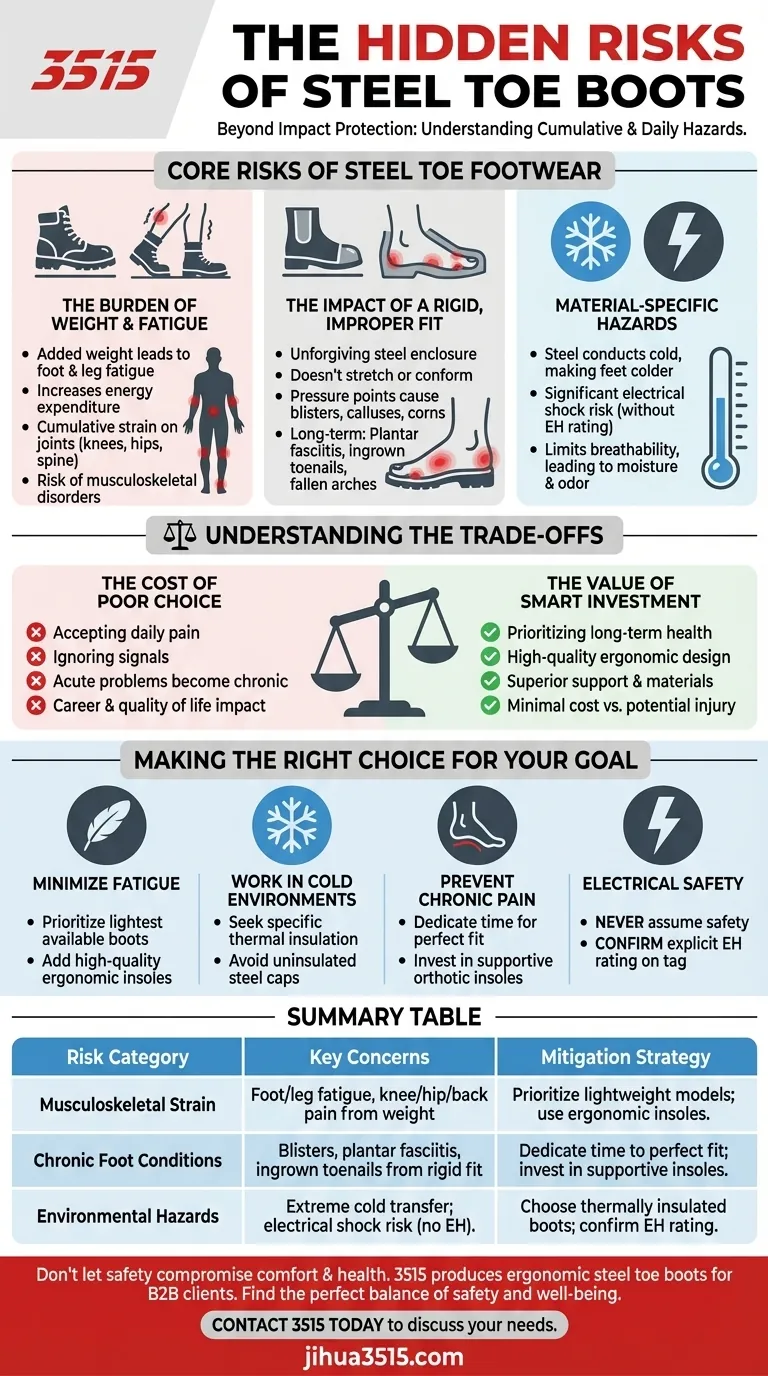

The Core Risks of Steel Toe Footwear

The protective qualities of steel create secondary challenges for the wearer. Understanding these issues is the first step toward preventing long-term discomfort and injury.

The Burden of Weight and Fatigue

Steel is heavy. This added weight at the end of your legs significantly increases the energy required to walk, leading directly to foot and leg fatigue over a long shift.

Over months and years, this constant strain can contribute to broader musculoskeletal disorders. The body compensates for heavy footwear, which can cause secondary pain and stress on the knees, hips, and even the spine.

The Impact of a Rigid, Improper Fit

The steel toe cap creates a completely unforgiving enclosure for your toes. Unlike leather or other materials, it will not stretch or conform to your foot's shape over time.

An improper fit is the leading cause of both acute and chronic problems. It creates pressure points that quickly lead to blisters, calluses, corns, and bruises.

More serious, long-term conditions can develop from this constant pressure and lack of proper support. These include plantar fasciitis (heel pain), ingrown toenails, and fallen arches or flat feet.

Material-Specific Hazards

Steel is an excellent conductor of energy. This property creates two distinct risks depending on your environment.

In cold conditions, the steel cap will rapidly conduct cold from the environment directly to your toes, making your feet feel colder than they would in other footwear.

More critically, steel conducts electricity. Unless the boot is specifically manufactured with an Electrical Hazard (EH) rating, it can pose a significant shock risk in environments with live electrical currents.

Finally, the rigid construction can limit breathability, leading to issues with sweat, moisture buildup, and foot odor.

Understanding the Trade-offs

It is a mistake to view safety footwear as a simple commodity. The choice between protection, comfort, and cost involves critical trade-offs that impact your daily well-being.

Safety Does Not Have to Mean Pain

Many professionals accept daily foot pain as a necessary price for on-the-job safety. This is a dangerous misconception.

Pain is your body's signal that something is wrong. Ignoring discomfort from poorly fitting or unsupportive boots allows acute problems like blisters to evolve into chronic conditions that can affect your career and quality of life.

A Higher Upfront Cost Can Prevent Long-Term Harm

High-quality boots from reputable manufacturers are engineered to mitigate the risks of weight and rigidity. They often feature better ergonomic design, superior arch support, and more advanced materials.

Viewing a well-made boot as a long-term investment in your health, rather than just a piece of required equipment, is essential. The cost of a good pair of boots is minimal compared to the potential for chronic injury and lost work time.

Making the Right Choice for Your Goal

Selecting the correct boot requires you to match its features to your specific work environment and physical needs.

- If your primary focus is minimizing fatigue: Prioritize the lightest available boot that meets your safety standard and consider adding high-quality aftermarket insoles to improve walking ergonomics.

- If your primary focus is working in cold environments: Seek out boots with a specific thermal insulation rating, as the steel cap will actively make your feet colder without it.

- If your primary focus is preventing chronic foot pain: Dedicate significant time to achieving a perfect fit and invest in supportive orthotic insoles to ensure proper arch and heel support.

- If your primary focus is electrical safety: Never assume a boot is safe for this work. You must confirm it has an explicit Electrical Hazard (EH) rating stamped on the tag.

Ultimately, choosing the right protective footwear is a direct investment in your long-term health and daily effectiveness on the job.

Summary Table:

| Risk Category | Key Concerns | Mitigation Strategy |

|---|---|---|

| Musculoskeletal Strain | Foot/leg fatigue, knee/hip/back pain from heavy weight | Prioritize lightweight models; use ergonomic insoles |

| Chronic Foot Conditions | Blisters, plantar fasciitis, ingrown toenails from rigid, ill-fitting cap | Dedicate time to achieving a perfect fit; invest in supportive insoles |

| Environmental Hazards | Extreme cold transfer; electrical shock risk (without EH rating) | Choose thermally insulated boots; confirm EH rating for electrical work |

Don't let safety footwear compromise your comfort and health. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality, ergonomically designed steel toe boots for distributors, brand owners, and bulk clients. Our boots are engineered to mitigate common risks, combining essential protection with superior comfort and support. Let us help you find the perfect balance of safety and well-being for your workforce.

Contact 3515 today to discuss your specific needs and explore our production capabilities for all types of safety shoes and boots.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How should one decide whether to wear steel-toe boots at work? Assess Your Risks for Optimal Foot Safety

- What additional safety features do steel toe work boots often include? Beyond the Steel Toe Cap

- Why might steel toes be a valuable feature in motorcycle boots? Balancing Protection & Control

- Are steel toe boots only for construction workers? Discover the Right Safety Footwear for Your Industry

- What are the key features of steel toe boots? Unmatched Impact Protection & Durability

- How do alloy safety toes compare to steel toes? Lighter Weight, Equal Protection

- Is there a downside to steel toe boots? Weighing Protection Against Daily Comfort

- What's the difference between safety toe and steel toe? Choose the Right Protective Footwear.