When comparing alloy and steel safety toes, the primary difference is weight, not strength. Alloy toes are significantly lighter—by 30% to 50%—while being engineered to meet the exact same safety and impact-resistance standards as their traditional steel counterparts.

The decision between alloy and steel toes is not a question of which is stronger, as both provide the same certified level of protection. The real choice comes down to balancing the lightweight comfort of alloy against the heavy-duty reputation of steel for your specific work environment.

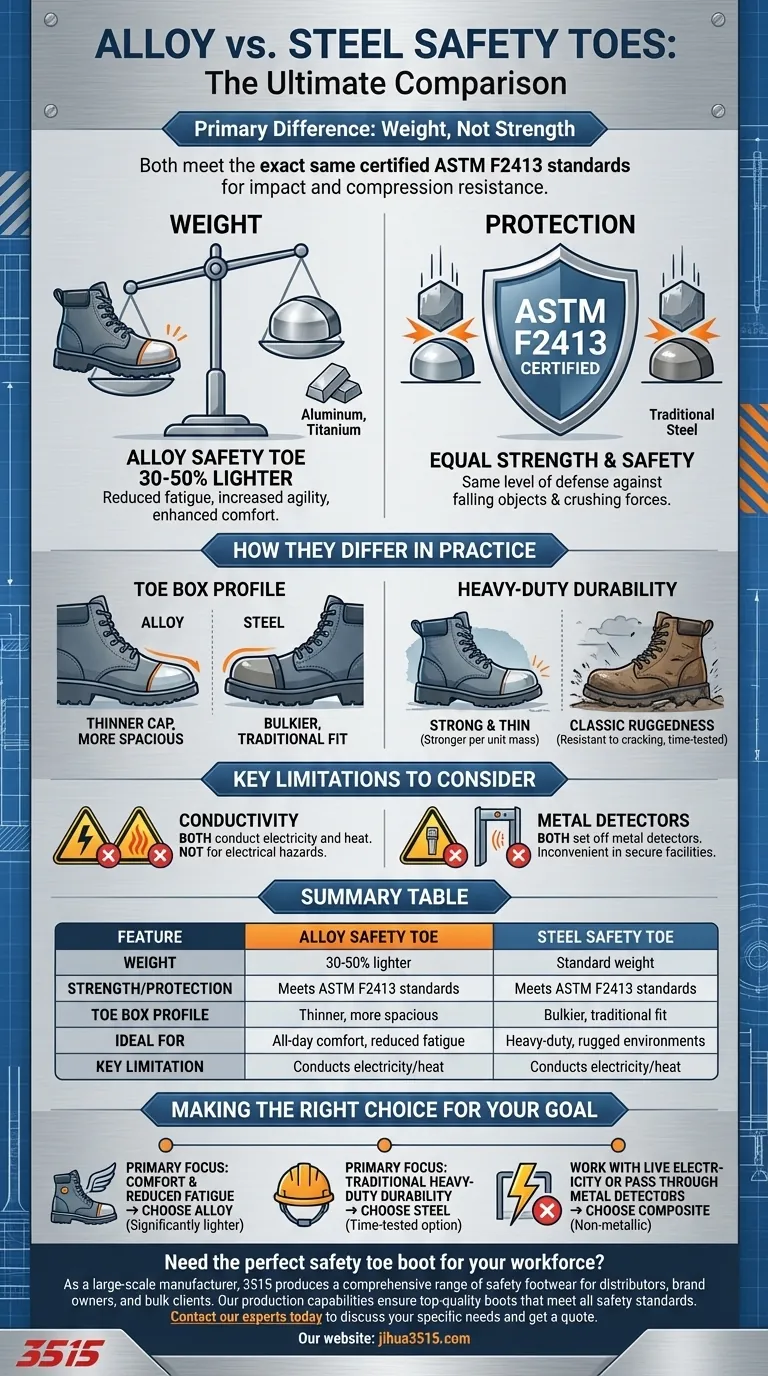

The Core Comparison: Weight vs. Protection

Your fundamental question revolves around two key metrics: how much they weigh and how well they protect you. The answer is simpler than many people assume.

The Clear Weight Advantage of Alloy

The most significant benefit of an alloy safety toe is its reduced weight. Made from materials like aluminum or titanium, these caps are 30-50% lighter than steel.

This weight reduction translates directly to user comfort, reducing fatigue over long shifts and making footwear feel less cumbersome and more agile.

Strength and Safety Are Equal

Despite the significant weight difference, both alloy and steel toes must pass the same ASTM F2413 safety standards for impact and compression resistance.

One is not inherently "stronger" than the other in terms of certified workplace protection. A boot with an alloy toe provides the same level of defense against falling objects or crushing forces as an equivalent steel-toed boot.

How They Differ in Practice

Beyond the core metrics of weight and strength, the materials have different physical properties that affect comfort and boot design.

Toe Box Room and Profile

Alloy metals are stronger per unit of mass than steel. This means manufacturers can create a thinner safety cap to achieve the same level of protection.

A thinner cap often results in a more spacious toe box, giving your toes more room and reducing the bulky feel common in some safety footwear.

Heavy-Duty Durability

Steel has long been the industry standard for a reason. It is an extremely durable and rugged material known for its resistance to cracking.

While alloy toes provide equal impact protection, steel's reputation is built on decades of performance in the most demanding industrial environments.

Key Limitations to Consider

Neither material is perfect for every situation. Understanding their shared limitations is crucial for making an informed decision.

Conductivity is a Factor for Both

Both steel and alloy are metals, meaning they will conduct electricity and heat.

If you work in an environment with electrical hazards, neither is the ideal choice. In such cases, a composite (non-metallic) safety toe is the appropriate solution.

Metal Detectors Will Be an Issue

Similarly, both materials will set off metal detectors. This can be a significant inconvenience in secure facilities or high-security job sites that require frequent screening.

Making the Right Choice for Your Goal

Your choice should be guided by your daily tasks and primary concerns on the job.

- If your primary focus is all-day comfort and reduced fatigue: Alloy is the superior choice due to its significantly lighter weight.

- If your primary focus is traditional, heavy-duty durability: Steel remains the classic, time-tested option trusted in the toughest conditions.

- If you work with live electricity or pass through metal detectors: Neither is appropriate; you should specifically seek out boots with non-metallic composite safety toes.

Understanding these key differences empowers you to select the footwear that truly supports your safety and comfort on the job.

Summary Table:

| Feature | Alloy Safety Toe | Steel Safety Toe |

|---|---|---|

| Weight | 30-50% lighter | Standard weight |

| Strength/Protection | Meets ASTM F2413 standards | Meets ASTM F2413 standards |

| Toe Box Profile | Thinner, more spacious | Bulkier, traditional fit |

| Ideal For | All-day comfort, reduced fatigue | Heavy-duty, rugged environments |

| Key Limitation | Conducts electricity/heat | Conducts electricity/heat |

Need the perfect safety toe boot for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Whether your team needs the lightweight comfort of alloy toes or the rugged durability of steel, our production capabilities ensure top-quality boots that meet all safety standards.

Contact our experts today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What types of steel are used in steel toe caps? Choose the Right Protection for Your Worksite

- How are steel and composite toe caps tested for safety? Discover the Uniform Standard

- How do aluminum safety toes compare to steel toes? A Guide to Lighter, Safer Footwear

- What are the features of steel-toe PVC boots? Unmatched Protection for Wet & Hazardous Work

- Why might someone choose a composite toe boot over a steel toe boot? Lighter, Safer, and More Comfortable.

- What are some alternatives to steel toe shoes? Explore Lighter, Safer Options for Your Workforce

- What are some common alternatives to steel-toe boots? Alloy & Composite Toes Explained

- What are the main types of toe protection? Steel, Composite, or Alloy for Your Work Boots