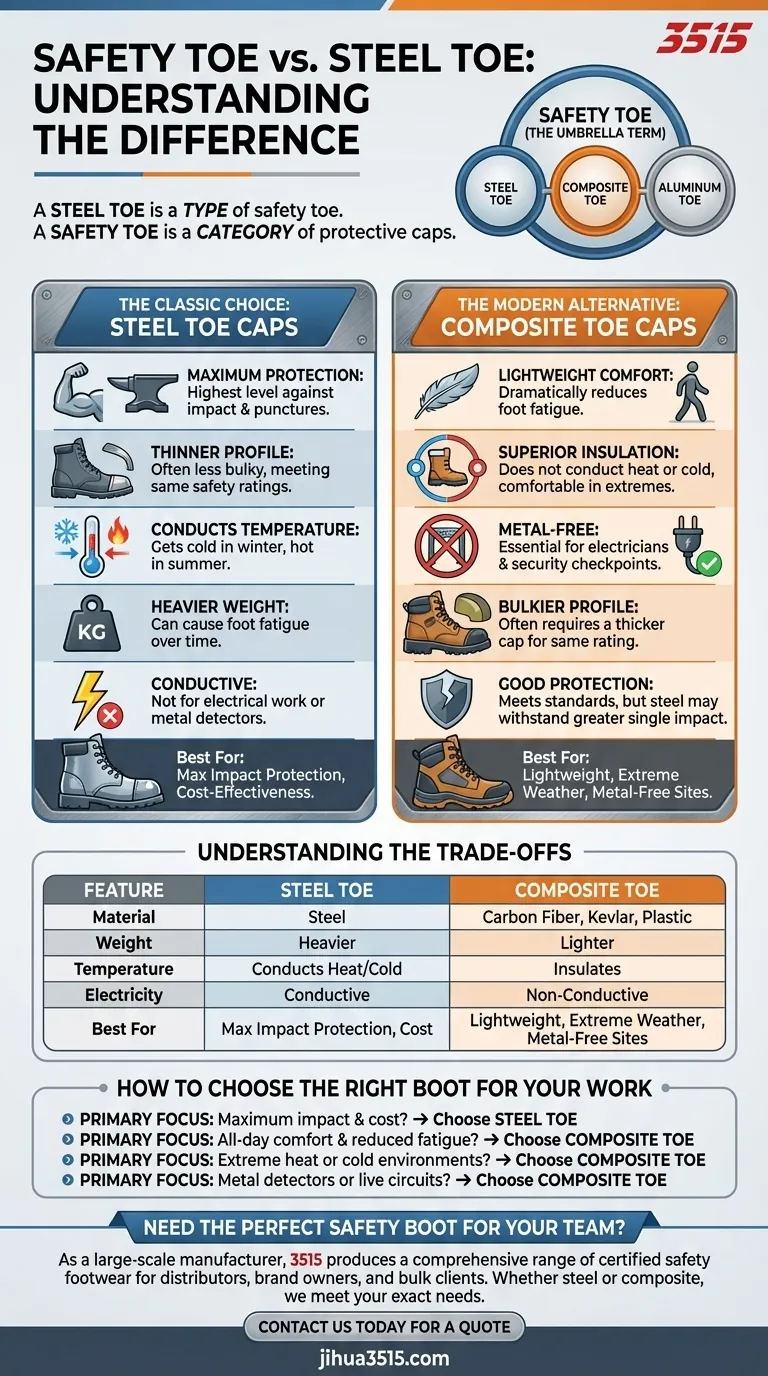

In the world of protective footwear, the terms "safety toe" and "steel toe" are often used interchangeably, but they are not the same. A steel toe is a specific type of safety toe. The term safety toe is a broad category that includes any protective cap—made from steel, composite materials, or aluminum alloy—designed to protect your feet from impact and compression.

The question isn't truly about "safety toe versus steel toe." The real decision is between different materials, primarily steel vs. non-metallic composites, each offering distinct benefits tailored to specific work environments and personal comfort.

What Defines a "Safety Toe"?

The Umbrella Term

A "safety toe" boot is any footwear that has a reinforced toe cap designed to meet specific safety standards for impact and compression resistance. These standards, such as those from ASTM International (ASTM F2413), provide a baseline for protection.

The Material Options

The protective cap that makes a boot a "safety toe" can be made from several materials. Steel is the traditional choice, but modern options have become widespread.

The most common materials are:

- Steel

- Composite materials (such as carbon fiber, Kevlar, or specialized plastics)

- Aluminum alloy

The Classic Choice: Steel Toe Caps

Maximum Protection

Steel has a long-standing reputation for providing the highest level of protection against punctures, crushing, and impact. For decades, it has been the industry benchmark for safety.

A Thinner Profile

Because of its inherent strength, a steel cap can often be made thinner than a composite cap while still meeting the same safety rating. This can sometimes result in a less bulky-looking boot.

The Modern Alternative: Composite Toe Caps

Lightweight Comfort

The most significant advantage of composite toes is their weight. They are considerably lighter than steel, which can dramatically reduce foot fatigue over a long workday.

Superior Insulation

Composite materials do not conduct heat or cold. This makes them far more comfortable than steel toes in extreme weather conditions, as they provide better insulation from the elements.

Metal-Free Environments

Composite toes are non-metallic and do not conduct electricity. This makes them the required choice for electricians and a convenient one for anyone who frequently passes through metal detectors.

Understanding the Trade-offs

Weight vs. Protection

While both steel and composite toes must meet the same minimum safety standards, steel can often withstand a greater single impact before failing. However, any boot should be replaced after a significant impact incident, regardless of the material.

Temperature and Comfort

The choice is clear when it comes to temperature. Steel will get cold in the winter and hot in the summer, directly transferring that temperature to your feet. Composites provide a much more stable and comfortable internal environment.

Workplace Mandates

Always check your site requirements. Some older or more traditional workplace specifications explicitly require steel toe boots as a standard for all personnel, leaving no room for alternatives.

How to Choose the Right Boot for Your Work

Choosing the correct boot comes down to understanding the demands of your job and environment.

- If your primary focus is maximum impact resistance and cost-effectiveness: A traditional steel toe is likely your best option, provided your work doesn't involve extreme temperatures.

- If your primary focus is all-day comfort and reduced fatigue: A lightweight composite toe will make a significant difference, especially if you walk long distances on the job.

- If your primary focus is working in extreme heat or cold: A composite toe is the superior choice for its essential thermal insulation properties.

- If your primary focus is passing through metal detectors or working near live circuits: A non-metallic composite toe is a mandatory requirement for both safety and convenience.

Ultimately, the best boot is the one that meets your specific safety requirements while providing the comfort you need to perform your job effectively.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Material | Steel | Carbon Fiber, Kevlar, Plastic |

| Weight | Heavier | Lighter |

| Temperature | Conducts Heat/Cold | Insulates |

| Electricity | Conductive | Non-Conductive |

| Best For | Max Impact Protection, Cost | Lightweight, Extreme Weather, Metal-Free Sites |

Need the Perfect Safety Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your priority is maximum protection with steel toes or all-day comfort with lightweight composites, we have the production capabilities to meet your exact needs.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What protective features do professional Safety Shoes provide in shipyard environments? Maximize Worker Safety

- What are the core advantages of using impact-resistant safety shoes in dairy farm mechanical work zones?

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites