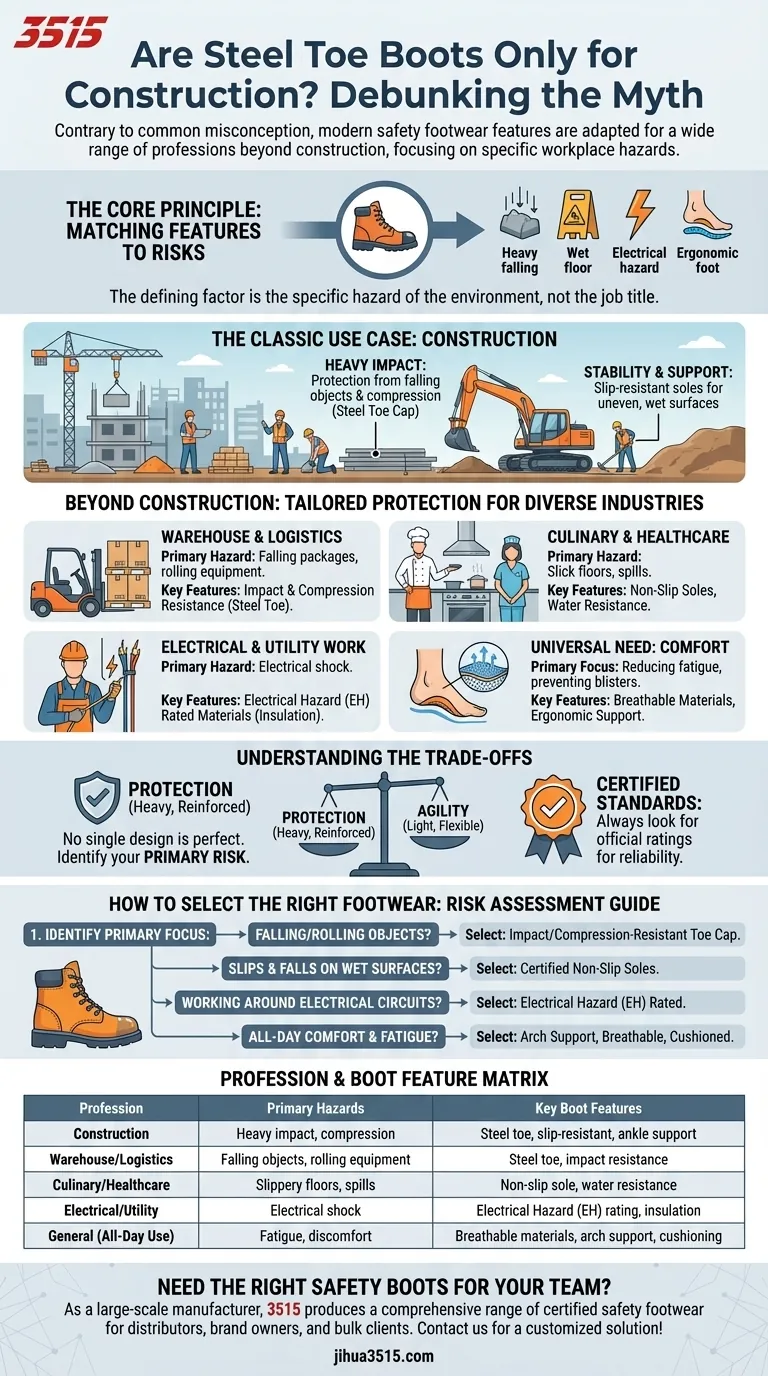

Contrary to a common misconception, steel toe boots are not exclusively for construction workers. While they are essential in construction, their protective features have been adapted for a wide range of professions, including warehouse logistics, culinary arts, healthcare, and any field where foot injuries are a significant risk. The defining factor is the specific hazard of the environment, not the job title.

The term "steel toe" refers to just one possible feature of modern safety footwear. The core principle is to match the boot's specific protective qualities—such as impact resistance, slip resistance, or electrical hazard protection—to the unique risks present in your workplace.

Why Construction Is the Classic Usecase

The association between steel toe boots and construction is strong for a clear reason: the environment is defined by heavy-impact and compression risks.

The Hazard of Heavy Impact

Construction sites are dynamic environments with heavy materials, tools, and equipment. The primary function of a steel toe cap is to protect a worker's toes from severe injury caused by falling objects or compression.

The Need for Stability and Support

Beyond impact, construction sites often feature uneven, wet, or slippery surfaces. Protective boots for this field provide built-in ankle and arch support and feature slip-resistant soles to prevent falls and sprains.

Beyond Construction: Matching Features to Professions

The evolution of safety footwear means that different industries can now leverage specific features tailored to their unique hazards. A boot's value is determined by how well its features mitigate the risks of a specific job.

Warehouse and Logistics

Workers in this field face similar impact risks from falling packages or rolling equipment like pallet jacks. Steel toe boots provide essential protection against these common hazards.

Culinary and Healthcare

In these environments, the primary risks are not from falling objects but from slick floors. Safety footwear designed for these professions prioritizes non-slip soles to prevent accidents and may also feature water resistance to protect from spills.

Electrical and Utility Work

For electricians or utility workers, a key danger is electrical shock. Specialized safety boots are made with electrical hazard (EH) rated materials that insulate the wearer from the ground, providing a critical layer of protection.

The Universal Need for Comfort

A feature that benefits every profession is comfort. Modern safety boots are designed with breathable materials and ergonomic support to reduce fatigue and prevent blisters for those who spend all day on their feet.

Understanding the Trade-offs

Selecting the right boot requires understanding that no single design is perfect for every situation. Protective features often come with inherent trade-offs.

Protection vs. Agility

A heavily reinforced boot designed for maximum impact protection will naturally be heavier and less flexible than a boot designed for slip resistance in a fast-paced kitchen.

The Myth of "One Boot Fits All"

The boot that offers best-in-class electrical hazard protection may not have the most aggressive non-slip sole. It is crucial to identify the primary risk of your job and choose footwear that excels in mitigating that specific danger.

The Importance of Certified Standards

A boot is not truly a "safety boot" unless it meets recognized industry safety standards. Always look for official ratings that certify the boot's protective capabilities, ensuring it has been tested and proven reliable for its stated purpose.

How to Select the Right Protective Footwear

To choose the correct boot, you must first conduct a simple risk assessment of your specific work environment.

- If your primary focus is protection from falling or rolling objects: Ensure your boot has a certified impact and compression-resistant toe cap.

- If your primary focus is preventing slips and falls on wet or slick surfaces: Prioritize boots with certified, high-traction, non-slip soles.

- If your primary focus is working around live electrical circuits: You must select boots specifically rated for Electrical Hazard (EH) protection.

- If your primary focus is all-day comfort and preventing fatigue: Look for features like enhanced arch support, breathable materials, and cushioned insoles.

Ultimately, choosing the right safety footwear is about understanding your environment's specific needs, not adhering to an outdated industry stereotype.

Summary Table:

| Profession | Primary Hazards | Key Boot Features |

|---|---|---|

| Construction | Heavy impact, compression | Steel toe, slip-resistant sole, ankle support |

| Warehouse/Logistics | Falling objects, rolling equipment | Steel toe, impact resistance |

| Culinary/Healthcare | Slippery floors, spills | Non-slip sole, water resistance |

| Electrical/Utility | Electrical shock | Electrical Hazard (EH) rating, insulation |

| General (All-Day Use) | Fatigue, discomfort | Breathable materials, arch support, cushioning |

Need the right safety boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots, tailored to meet the specific hazards of your industry—from steel toe and EH-rated boots to non-slip soles and all-day comfort designs. Ensure your workforce is properly protected with reliable, high-quality footwear. Contact us today for a customized solution!

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What are the benefits of steel-toe boots in terms of impact resistance? Get Maximum Protection for Your Workforce

- What steps should employers take to ensure workers wear steel toe shoes? Build a Robust Safety Compliance System

- What are the key differences between steel toe and composite toe caps? Choose the Right Safety for Your Job

- What are the different types of materials used in the toe portion of safety toe work boots? A Guide to Steel, Alloy & Composite

- What is the primary benefit of wearing steel toe boots? Uncompromising Protection Against Crushing Injuries

- Why is it necessary to conduct mechanical strength evaluations on polycarbonate toecaps? Ensure Impact Safety & Comfort

- How are steel and composite toe caps tested for safety? Discover the Uniform Standard

- What are the benefits of anti-fatigue mats for steel toe boot wearers? A Guide to Managing Workplace Comfort