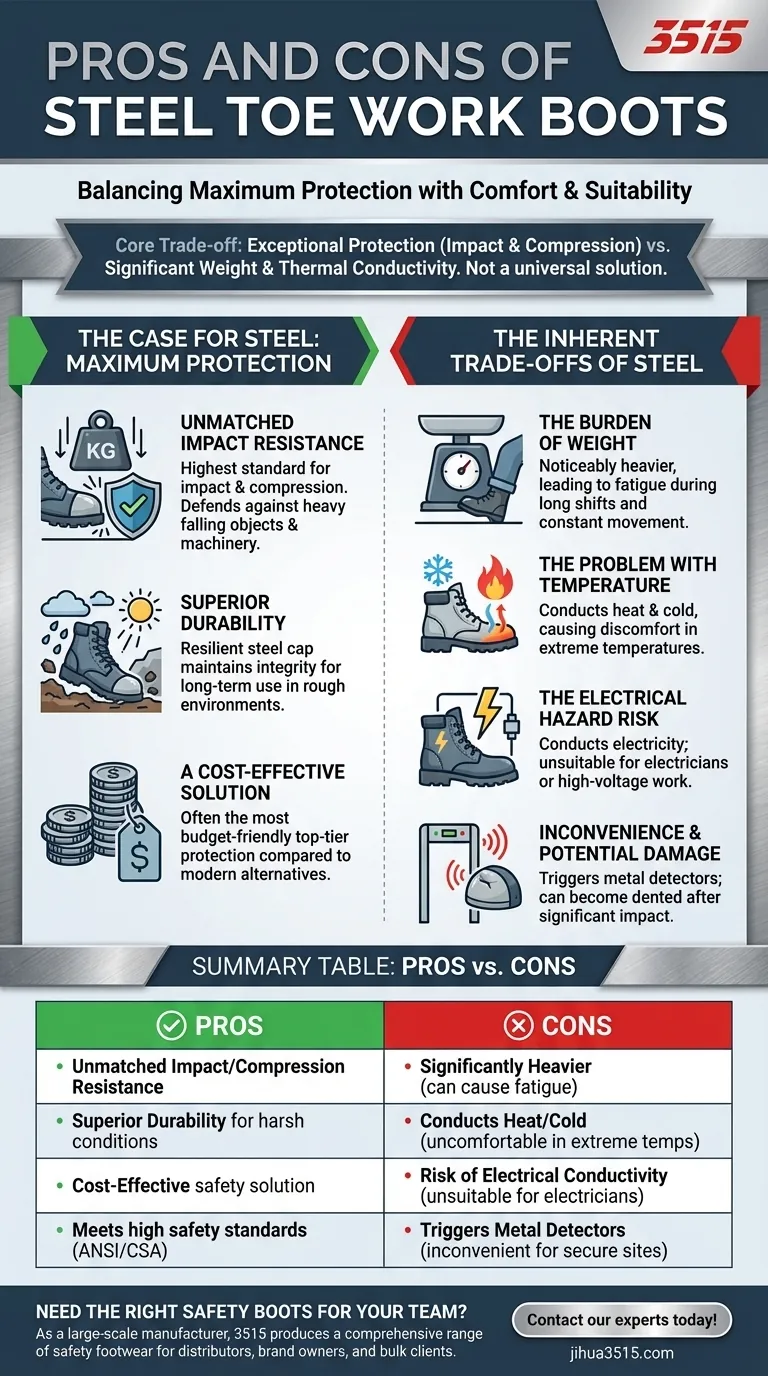

At its core, the primary advantage of a steel toe work boot is its exceptional protection against impact and compression, while its main disadvantages are significant weight and its tendency to conduct heat and cold. This classic safety technology offers heavy-duty defense but comes with notable trade-offs in comfort and environmental suitability.

While steel toe boots provide the highest standard of protection for heavy-duty work, their inherent properties—weight and conductivity—make them a specialized tool, not a universal solution for every work environment.

The Case for Steel Toe Boots: Maximum Protection

Steel toe boots have remained a cornerstone of workplace safety for decades because they excel at their primary function: protecting your feet from serious injury in hazardous environments.

Unmatched Impact Resistance

Steel caps offer the highest available standard for impact and compression resistance. They are engineered to withstand immense force from falling objects or heavy machinery.

This makes them the definitive choice in fields like heavy construction, manufacturing, and logging where the risk of crushing injuries is most severe.

Superior Durability

The materials and construction of traditional steel toe boots are designed for longevity in harsh conditions. The steel itself is incredibly resilient, ensuring the protective cap maintains its integrity over the long term.

A Cost-Effective Solution

Compared to more modern alternatives like composite or alloy toe boots, steel toe boots are often the most budget-friendly option. They provide top-tier protection without the higher price tag associated with lighter-weight materials.

The Inherent Trade-offs of Steel

The very properties that make steel strong also create its primary disadvantages. Understanding these limitations is critical to choosing the right boot.

The Burden of Weight

Steel is dense, making these boots noticeably heavier than other safety footwear. This added weight can lead to fatigue over a long shift, particularly for workers who are constantly on the move.

The Problem with Temperature

Metal is an excellent conductor. In cold weather, the steel cap can draw heat away from your feet, making them feel frigid. Conversely, in hot environments, it can absorb and hold heat, leading to discomfort and sweating.

The Electrical Hazard Risk

Because steel conducts electricity, standard steel toe boots are unsuitable for electricians or anyone working in environments with a high risk of electrical shock. While some are rated for electrical hazards (EH), the inherent conductivity is a risk factor.

Inconvenience and Potential for Damage

Steel toe boots will reliably set off metal detectors, making them impractical for workers who must pass through security checkpoints frequently. While durable, the steel cap can also become dented after a significant impact, which can compromise its structural integrity.

How to Maximize Comfort and Fit

Even with the inherent drawbacks, the right fit and accessories can dramatically improve the experience of wearing steel toe boots all day.

The Critical Role of Proper Socks

Never underestimate the importance of your socks. Choose materials like Merino wool, which are breathable, moisture-wicking, and help regulate temperature in both hot and cold conditions.

Compression socks can also aid circulation and reduce swelling, which is especially beneficial during long shifts spent standing or walking.

Ensuring the Right Fit

An improper fit is a primary source of discomfort. Steel toe boots often provide a roomier toe box, but ensure there is no rubbing or pinching. The steel cap should not press against your toes when you stand, walk, or crouch.

Making the Right Choice for Your Work

Selecting the correct safety boot requires matching the boot's features to the specific demands and hazards of your job.

- If your primary focus is maximum impact protection: Steel toe boots are the classic, cost-effective standard for heavy industry, construction, and environments with heavy machinery.

- If you work in extreme heat or cold: The thermal conductivity of steel is a significant disadvantage, and a composite toe may be a more comfortable choice.

- If you are an electrician or work in high-security areas: Steel is a poor choice due to its electrical conductivity and its effect on metal detectors.

- If your priority is all-day mobility and minimizing fatigue: The heavy weight of steel toe boots may lead you to consider lighter-weight composite or alloy alternatives.

Ultimately, choosing the right protective footwear is about selecting the most effective tool for your specific task and environment.

Summary Table:

| Pros | Cons |

|---|---|

| Unmatched Impact/Compression Resistance | Significantly Heavier (can cause fatigue) |

| Superior Durability for harsh conditions | Conducts Heat/Cold (uncomfortable in extreme temps) |

| Cost-Effective safety solution | Risk of Electrical Conductivity (unsuitable for electricians) |

| Meets high safety standards (e.g., ANSI/CSA) | Triggers Metal Detectors (inconvenient for secure sites) |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear, including steel toe boots, for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots designed for durability and protection.

We can help you select or manufacture the perfect safety footwear that balances protection, comfort, and the specific demands of your work environment.

Contact our experts today to discuss your needs and get a quote!

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- How does an alloy toe compare to a steel toe? Lighter Weight, Same Protection

- What are the key features of steel toe shoes? Maximum Impact Protection for Industrial Work

- What are the benefits of steel-toed shoes? Maximum Protection for Heavy-Duty Work

- How can you optimize the fit of steel toe boots for better comfort? A Complete Guide to Custom Fit

- What are the characteristics of a steel toe? Maximum Impact Protection Explained

- What does OSHA say about steel toe boots? A Guide to Compliant Footwear

- How can you quickly break in steel toe boots? A Fast, Pain-Free Method for Comfort

- What are the differences between steel toe and composite toe work boots? Choose the Right Safety for Your Job