In a direct comparison, an alloy toe cap provides the same certified level of impact protection as a traditional steel toe cap. The fundamental difference lies in the material: alloy toes are crafted from lightweight metals like aluminum or titanium, making them significantly lighter than steel.

The choice between an alloy and steel toe is not about safety, as both must meet the same protective standards. The decision ultimately comes down to balancing weight, comfort, and cost for your specific work environment.

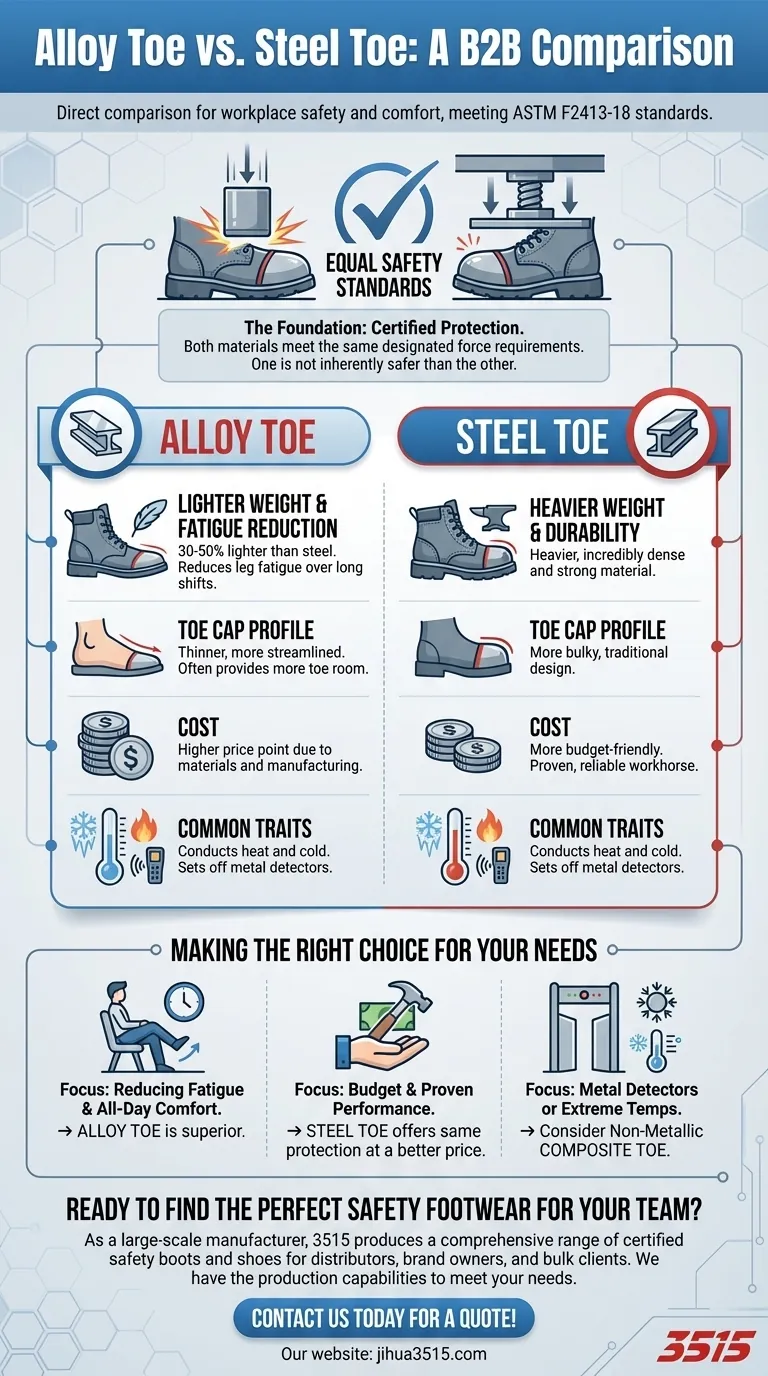

The Foundation: Equal Safety Standards

Before comparing features, it's critical to understand that all legitimate safety footwear is built to meet specific, measurable standards. This is the baseline from which all comparisons should start.

What the Standards Mean

All safety toe caps, regardless of material, are rated to meet standards like ASTM F2413-18. This certification ensures the toe cap can withstand the same designated force from impacts and compression.

A boot with an alloy toe and one with a steel toe that both carry this rating offer the exact same level of protection against a falling object. One is not inherently "safer" than the other in a certified boot.

Key Differences Beyond the Standards

With safety being equal, the decision shifts to the practical, day-to-day experience of wearing the boots. The material differences have a direct impact on comfort and usability.

Weight and Fatigue

This is the most significant advantage of an alloy toe. By using lighter metals, manufacturers can reduce the overall weight of the boot, sometimes by 30-50% compared to steel.

This weight reduction directly translates to less leg fatigue over a long shift, a crucial factor for anyone who is on their feet all day.

Toe Cap Profile

Alloy metals can be engineered to be thinner than steel while still providing the same strength. This allows for a less bulky toe cap.

A thinner toe cap means the boot can have a more streamlined profile, appearing more like a standard boot and often providing more room for your toes to move.

Cost

The materials and manufacturing processes for alloy toe caps are more expensive than those for traditional steel.

As a result, alloy toe boots almost always come at a higher price point than their steel toe equivalents.

Understanding the Trade-offs

Choosing the right boot means being aware of the myths and realities associated with each material.

The Myth of "Heavy-Duty"

Many people associate the weight of a steel toe with superior strength. While steel is incredibly dense and strong, this does not mean it offers more protection in a safety boot.

The design and certification of the toe cap are what guarantee protection, not the raw weight of the material itself.

The Metal Disadvantage

Both steel and alloy are metals, meaning they will conduct heat and cold. In extremely cold environments, this can lead to discomfort.

They will also both set off metal detectors, a consideration for workers who must pass through security screenings regularly. In those specific cases, a non-metallic composite toe is often the ideal solution.

Making the Right Choice for Your Needs

Selecting the best safety toe is about aligning the material's properties with your daily tasks and personal priorities.

- If your primary focus is reducing fatigue and all-day comfort: Alloy toe is the superior choice, as its lighter weight makes a noticeable difference over a full workday.

- If your primary focus is budget and proven performance: Steel toe offers the same certified protection at a more accessible price point, making it a reliable workhorse.

- If you frequently pass through metal detectors or work in extreme temperatures: You should expand your search to include non-metallic composite toes, which solve these specific challenges.

Ultimately, choosing the right safety boot is about investing in the tool that best supports your work, comfort, and safety each day.

Summary Table:

| Feature | Alloy Toe | Steel Toe |

|---|---|---|

| Safety Certification | Meets ASTM F2413-18 (Same as Steel) | Meets ASTM F2413-18 (Same as Alloy) |

| Weight | Lighter (30-50% lighter than steel) | Heavier |

| Toe Box Profile | Thinner, more streamlined | Bulkier |

| Cost | Higher | More budget-friendly |

| Heat/Cold Conduction | Yes (conducts temperature) | Yes (conducts temperature) |

| Sets off Metal Detectors | Yes | Yes |

Ready to find the perfect safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Whether your priority is the lightweight comfort of an alloy toe or the proven value of a steel toe, we have the production capabilities and expertise to meet your needs.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- How do safety shoes protect you? A Guide to Essential Footwear Safety Features

- What's the difference between steel toe and safety-toe boots? Choose the Right Protection for Your Job

- What should I look for in a safety shoe? Find the Perfect Protection for Your Job

- Is safety toe better than steel toe? A Guide to Choosing the Right Protection

- Are safety shoes worth it? The Critical Investment in Workplace Safety & Foot Health