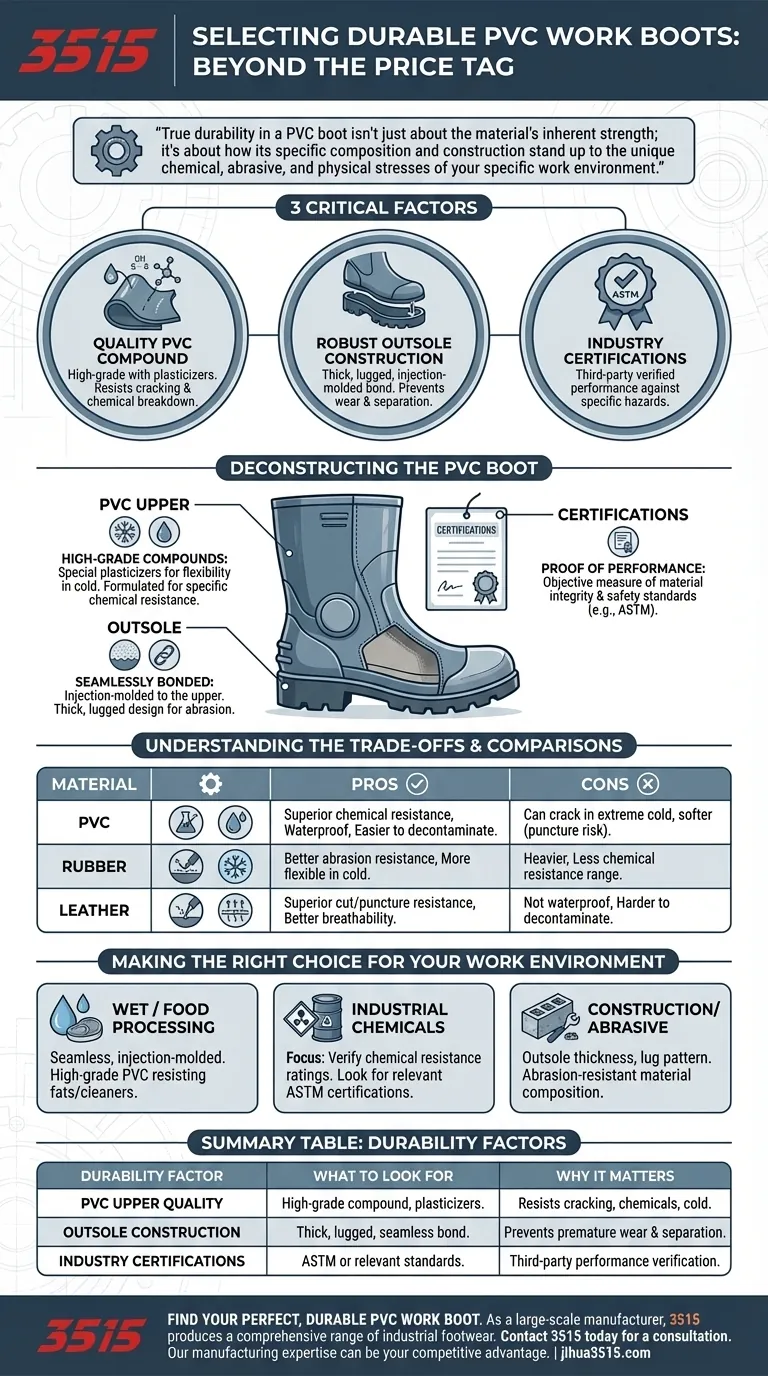

When selecting PVC work boots for durability, you must look beyond the price tag and focus on three critical factors: the quality of the PVC compound, the construction of the outsole, and the presence of industry certifications. High-grade PVC resists cracking and chemical breakdown, a robustly attached outsole prevents premature wear and separation, and official certifications confirm the boot has been tested to withstand specific workplace hazards.

True durability in a PVC boot isn't just about the material's inherent strength; it's about how its specific composition and construction stand up to the unique chemical, abrasive, and physical stresses of your specific work environment.

Deconstructing the PVC Boot: Key Durability Markers

Understanding what makes a boot last requires looking at its individual components. A durable boot is a system where the material, construction, and design work together to resist failure.

The PVC Upper: More Than Just Plastic

The main body of the boot, or upper, is your primary barrier. High-grade PVC compounds include special plasticizers that enhance flexibility and prevent cracking, especially in cold temperatures where cheaper materials become brittle.

This material quality is also crucial for chemical resistance. Different PVC formulas offer varying levels of protection against acids, bases, fats, and oils. A boot that is durable in a wet field may quickly degrade in an industrial plant if the PVC isn't formulated for that specific exposure.

The Outsole: Your First Line of Defense

The outsole is the part of the boot that contacts the ground and endures the most physical wear. Its durability depends on both its material composition and its bond to the upper.

Look for a thick, deeply lugged outsole designed for abrasion resistance. Critically, ensure it is seamlessly bonded to the upper, often through an injection-molding process. This creates a single, waterproof unit that is highly resistant to sole separation, a common failure point in lower-quality boots.

Certifications: The Proof of Performance

Industry certifications, such as those from ASTM International, are an objective measure of durability and safety. While often associated with features like safety toes or electrical hazard protection, these standards also involve tests for material integrity.

A certified boot has been verified by a third party to meet specific performance criteria. This serves as a reliable indicator that the manufacturer has invested in quality materials and construction capable of withstanding rigorous testing that simulates demanding work conditions.

Understanding the Trade-offs of PVC

No material is perfect for every situation. Being an informed buyer means understanding the inherent limitations of PVC to ensure it aligns with your needs.

Common Failure Points

Even well-made PVC boots can fail under the wrong conditions. The most common issues are cracking from repeated flexing in extreme cold, punctures from sharp objects (as PVC is softer than heavy-duty rubber or leather), and degradation from exposure to chemicals not covered by its resistance rating.

PVC vs. Other Materials

Compared to rubber, PVC often offers superior resistance to a wider range of chemicals and is typically lighter. However, high-grade rubber may offer better abrasion resistance and flexibility in the cold.

Compared to leather, PVC provides superior waterproofing and is easier to decontaminate. However, leather is far more resistant to cuts and punctures and offers significantly better breathability.

Making the Right Choice for Your Work

To select the most durable boot, you must match its specific features to the demands of your job.

- If your primary focus is working in wet, agricultural, or food processing environments: Prioritize seamless, injection-molded boots with a high-grade PVC that resists animal fats and common cleaning agents.

- If your primary focus is exposure to industrial chemicals or hydrocarbons: Verify the boot's specific chemical resistance ratings against the substances you handle and look for relevant ASTM certifications.

- If your primary focus is general construction on abrasive surfaces: Pay closest attention to the outsole's thickness, lug pattern, and material composition for maximum wear resistance.

Ultimately, choosing the right boot is about matching its specific material and construction strengths to the challenges it will face every day.

Summary Table:

| Durability Factor | What to Look For | Why It Matters |

|---|---|---|

| PVC Upper Quality | High-grade compound with plasticizers for flexibility | Resists cracking, chemical breakdown, and cold-weather brittleness |

| Outsole Construction | Thick, lugged outsole, seamlessly bonded (injection-molded) | Prevents premature wear and sole separation; ensures waterproofing |

| Industry Certifications | ASTM or other relevant safety standards | Third-party verification of performance against specific workplace hazards |

Find Your Perfect, Durable PVC Work Boot

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. We understand that durability is non-negotiable. Our production capabilities encompass all types of PVC boots, engineered with high-grade compounds and robust construction to meet the specific demands of your work environment—from chemical resistance to abrasion protection.

Let us help you source the right boots that combine safety, comfort, and long-lasting performance. Contact 3515 today for a consultation and discover how our manufacturing expertise can become your competitive advantage.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are the key considerations for firefighters' boots besides hazard protection? Unlock Peak Performance & Safety

- What are the best storage practices for fire boots? Keep Your Gear Ready & Extend Its Lifespan

- What are some user experiences with packer boots? Unmatched Durability & All-Day Comfort

- What are the alternatives to work boots for women? Find the Perfect Fit for Your Job

- What are the key features of women's work boots? Secure Protection & True Anatomical Fit

- Why do breeder farms need higher-spec protective boots? Ensure Biosecurity for High-Value Genetic Assets

- What are some common concerns about wildfire boots and how can they be addressed? Find the Right Fit for Your Mission

- What are some popular brands for cowboy boots for farm work? Find Durable, Safe & Comfortable Options