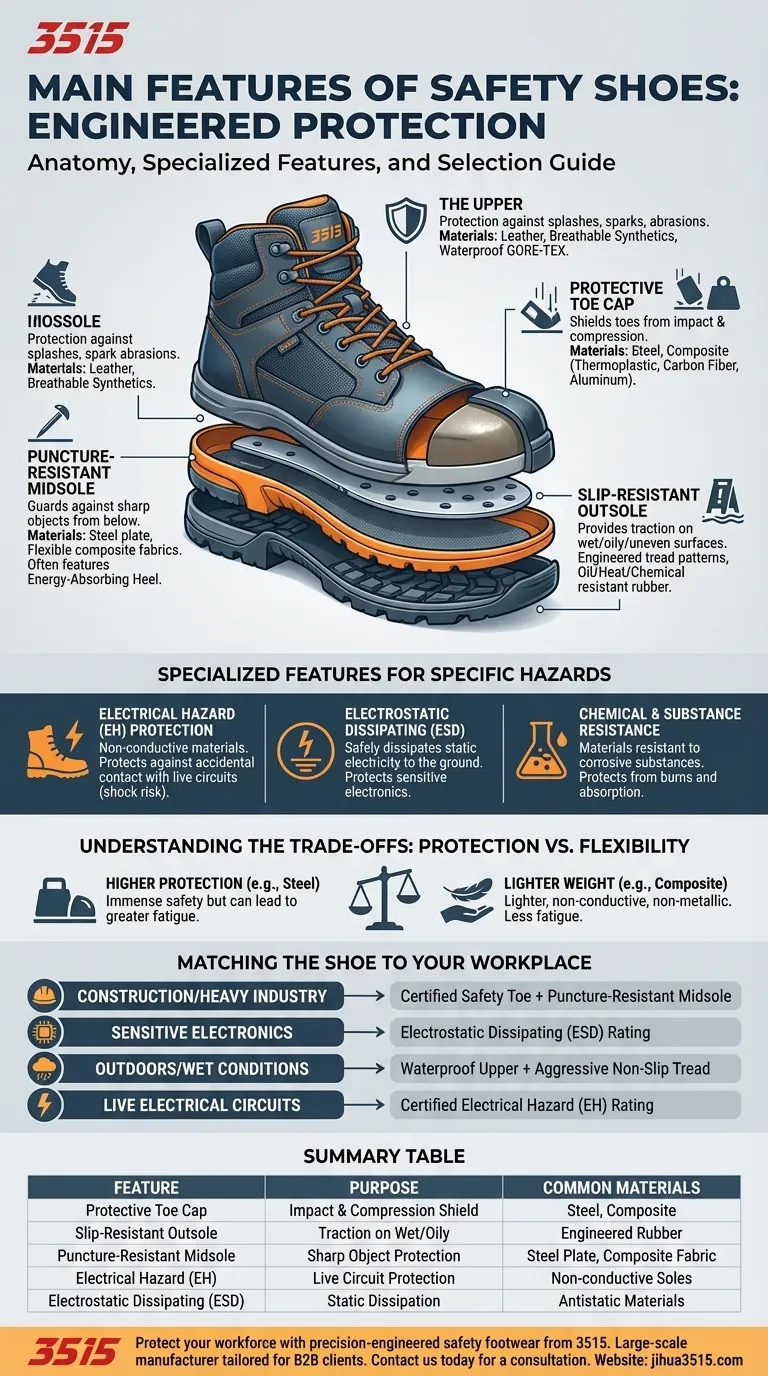

The primary features of a safety shoe are a reinforced toe cap for impact protection, a slip-resistant outsole for traction, and a puncture-resistant midsole to guard against sharp objects from below. These core components work together within a durable structure to protect the wearer from the most common workplace foot injuries.

A safety shoe is more than just a steel toe. It is an engineered system of protective features where each component is chosen to mitigate specific, predictable workplace hazards, from electrical shock to chemical spills.

The Anatomy of Protection: Core Components Explained

Understanding a safety shoe begins with its fundamental protective parts. While they look like regular boots or shoes, the materials and construction are purpose-built for defense.

The Protective Toe Cap

This is the most well-known feature. Its purpose is to shield the toes from impact (falling objects) and compression (rolling objects).

Toe caps are typically made from steel, which offers maximum protection, or composite materials like thermoplastics, carbon fiber, or aluminum. Composite toes are lighter and do not conduct electricity, making them ideal for certain environments.

The Outsole

The outsole is the layer that makes direct contact with the ground. Its primary safety function is providing slip resistance on wet, oily, or uneven surfaces.

The material and tread pattern are engineered to channel away liquids and maximize grip. Outsoles can also be designed for resistance to heat, chemicals, or oil.

The Midsole

Located between the insole and the outsole, the midsole provides cushioning and support. In safety footwear, it often contains a puncture-resistant plate.

This plate, made of steel or flexible composite fabrics, prevents sharp objects like nails or glass from penetrating the bottom of the shoe. Many midsoles also feature an energy-absorbing heel to reduce the impact on your joints during a long workday.

The Upper

The "upper" is the entire part of the shoe that covers the foot. The material chosen for the upper provides protection against splashes, sparks, and abrasions.

Common materials include durable leather for heavy industry or breathable synthetics for lighter work. Specialized uppers may also include features like GORE-TEX liners for waterproof yet breathable performance.

Specialized Features for Specific Hazards

Beyond the core components, many safety shoes include advanced features designed to protect against less common but highly dangerous workplace risks.

Electrical Hazard (EH) Protection

Shoes with an EH rating have soles and heels made from non-conductive, electrical-insulating materials. They are designed to protect the wearer from accidental contact with live electrical circuits, reducing the potential for electric shock.

Electrostatic Dissipating (ESD)

Unlike EH shoes, ESD (or Antistatic) footwear is designed to safely dissipate static electricity from the body to the ground. This prevents a static discharge that could damage sensitive electronic equipment or ignite flammable materials.

Chemical and Substance Resistance

For environments with chemical exposure, safety shoes are constructed with materials resistant to specific corrosive substances. This protects the foot from burns, irritation, and absorption of hazardous liquids.

Understanding the Trade-offs

Selecting the right safety shoe requires balancing protection with practical needs. No single shoe is perfect for every job.

Protection vs. Weight and Flexibility

Generally, higher levels of protection mean a heavier and more rigid shoe. A steel toe and steel puncture plate offer immense safety but can lead to greater fatigue over a long shift compared to lighter composite alternatives.

Material Choices Matter

Steel toes are the traditional standard for impact resistance, but composite toes are lighter, don't set off metal detectors, and don't conduct heat or cold. Likewise, a rugged leather upper is durable but may be less breathable than a modern synthetic one.

The Myth of a "One-Size-Fits-All" Solution

The features that make a shoe ideal for a construction site (e.g., maximum impact protection) make it unsuitable for an electronics assembly line where ESD properties are critical. Always match the shoe's features to the specific hazards of your environment.

Matching the Shoe to Your Workplace

Use your primary work environment as the guide to selecting the right combination of features.

- If your primary focus is construction or heavy industry: You need a shoe with a certified safety toe (steel or composite) and a puncture-resistant midsole.

- If your primary focus is working with sensitive electronics: You need a shoe with an Electrostatic Dissipating (ESD) rating to prevent static damage.

- If your primary focus is working outdoors or in wet conditions: Prioritize a waterproof upper and an outsole with an aggressive, non-slip tread pattern.

- If your primary focus is working near live electrical circuits: You must have a shoe with a certified Electrical Hazard (EH) rating for insulation.

Choosing the right safety footwear is a critical investment in your personal protection.

Summary Table:

| Feature | Purpose | Common Materials/Examples |

|---|---|---|

| Protective Toe Cap | Shields toes from impact and compression | Steel, Composite (Thermoplastics, Carbon Fiber) |

| Slip-Resistant Outsole | Provides traction on wet/oily surfaces | Engineered tread patterns, Oil-resistant rubber |

| Puncture-Resistant Midsole | Prevents sharp object penetration | Steel plate, Composite fabrics |

| Electrical Hazard (EH) Rating | Protects against live electrical circuits | Non-conductive soles and heels |

| Electrostatic Dissipating (ESD) | Safely dissipates static electricity | Antistatic materials |

Protect your workforce with precision-engineered safety footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of safety shoes and boots tailored for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, from steel-toe boots for heavy industry to ESD-rated shoes for electronics assembly.

We combine durable materials, certified safety features, and ergonomic design to ensure optimal protection and comfort for your team. Let us help you mitigate workplace hazards with footwear built to your exact specifications.

Contact us today for a consultation and discover how 3515 can be your trusted partner in workplace safety.

Visual Guide

Related Products

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What is the key difference between work shoes and safety shoes? The Critical Feature You Need to Know

- What is the impact of a centralized organizational supply of safety shoes? Building Safety Equity and Climate

- Which type of safety-toe boot is better for cold weather? Focus on Insulation & Waterproofing

- How does the production process contribute to the lightness of composite toe caps? Achieve Superior Comfort & Safety

- How does the molding method work in safety shoes manufacturing? Unlock Unmatched Durability and Protection

- How should safety footwear be cared for? A Practical Guide to Extend Boot Life & Safety

- How does screening PET/PA blend ratios benefit safety shoe linings? Achieve Zero Charge & Anti-Static Safety

- What is the function of a climate simulation chamber for Safety Shoes? Enhancing Physiological Performance and Safety