Proper care for safety footwear is a system of routine cleaning, consistent inspection, and timely replacement. It involves more than just keeping boots clean; it means actively maintaining their protective features, from applying water-resistant coatings to replacing worn insoles, to ensure they function as intended.

The core purpose of safety footwear maintenance is not cosmetic. It is a critical safety procedure designed to preserve the specific protective technologies engineered into the footwear, ensuring it remains compliant with safety standards and capable of preventing serious injury.

Why Footwear Care is a Critical Safety Function

Understanding the "why" behind maintenance transforms it from a chore into a crucial part of your personal protective equipment (PPE) strategy. Neglected footwear is a liability.

Preserving Protective Integrity

Safety footwear is an engineered system with components like protective toe caps, puncture-resistant soles, and materials designed for electrical hazard protection.

Regular wear, exposure to moisture, and chemical contact can degrade these materials, compromising their ability to protect you from impact, compression, or shock.

Ensuring Regulatory Compliance

OSHA regulations (specifically 29 CFR 1910.136) mandate that employers ensure workers use protective footwear that meets standards like ASTM 2413-18.

Footwear that is damaged, worn out, or compromised fails to meet these standards. Proper care and inspection are essential for maintaining compliance.

Maintaining All-Day Support and Stability

Beyond acute injuries, footwear provides critical ankle and arch support. Worn-out components can lead to fatigue and musculoskeletal issues.

Replacing removable insoles every few months helps maintain proper cushioning and support, reducing physical strain over long shifts.

A Practical Guide to Footwear Maintenance

A simple, consistent routine is the most effective way to maximize the life and protective capabilities of your safety footwear.

The Daily & Weekly Routine: Cleaning

Always follow the manufacturer's specific instructions for cleaning, as different materials (like leather vs. synthetic) require different methods.

Regularly removing dirt and contaminants prevents the premature breakdown of upper materials and stitching.

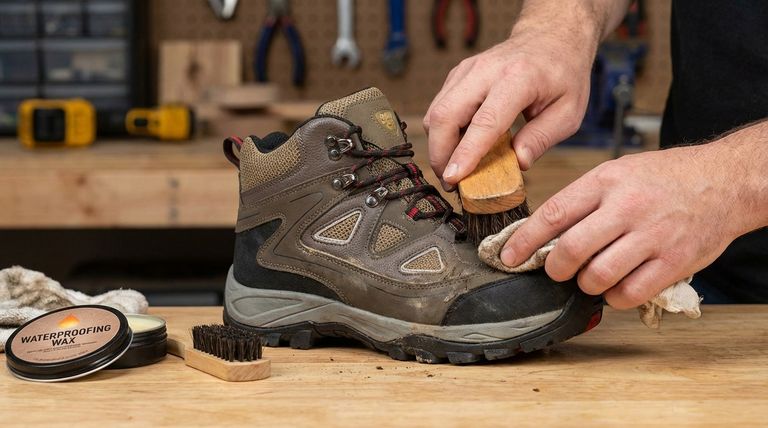

Applying Protective Coatings

For leather or other porous materials, using a recommended protective coating can significantly enhance water resistance.

This helps keep feet dry and prevents moisture from degrading the boot's structural materials and electrical resistance properties.

The Critical Role of Regular Inspection

A visual inspection should be a frequent habit. Look for cracks in the sole, separation between the upper and the outsole, and deep cuts or gouges.

Pay close attention to the tread. Worn-out treads dramatically increase the risk of slips and falls, one of the most common workplace accidents.

Knowing When to Repair vs. Replace

The most critical maintenance decision is recognizing when a boot is beyond repair and has become a safety hazard.

Clear Signs Replacement is Non-Negotiable

You must replace your footwear immediately if you see these signs of critical failure:

- A dent or crack in the steel or composite toe cap.

- Any protective component (like a puncture plate or toe cap) becomes visible through the outer material.

- The sole begins to separate from the upper part of the boot.

- The tread is worn smooth, eliminating its slip-resistant properties.

The Risk of "Invisible" Damage

Some damage is not visible. A single severe impact can compromise the integrity of a toe cap, even if it appears undamaged externally.

Likewise, the electrical shock resistance of footwear is significantly reduced by wear and in wet conditions. Do not assume the protection is still fully functional in older, heavily worn boots.

Minor Repairs: What's Acceptable?

Replacing components like laces and insoles is considered standard, acceptable maintenance.

However, attempting to repair structural damage, such as re-gluing a separated sole or patching a hole over the toe cap, is unsafe and renders the footwear non-compliant.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your work environment and the primary risks you face.

- If your primary focus is general durability: Prioritize routine cleaning and inspection to identify and address wear and tear before it becomes a critical failure.

- If your primary focus is working in wet or chemical environments: Regularly apply protective coatings and pay close attention to the integrity of all seams and the bond between the sole and the upper.

- If your primary focus is high-risk impact or electrical hazard protection: Adhere to a strict policy of replacing footwear after any significant impact event, regardless of visible damage.

Proactive care transforms safety footwear from a simple requirement into a reliable instrument of personal protection.

Summary Table:

| Maintenance Task | Frequency | Key Benefit |

|---|---|---|

| Visual Inspection (soles, toe cap) | Daily/Before Use | Identifies critical damage early |

| Cleaning (per manufacturer) | Weekly/Daily (as needed) | Prevents material breakdown |

| Apply Protective Coatings | As needed/Seasonally | Enhances water & chemical resistance |

| Replace Worn Insoles | Every 3-6 months | Maintains support and reduces fatigue |

| Check for Sole Separation | Weekly | Ensures structural integrity |

| Assess Tread Wear | Weekly | Prevents slips and falls |

Ensure your workforce is equipped with durable, compliant safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, from steel-toe boots for high-impact environments to electrical hazard-resistant designs.

We help you provide reliable PPE that meets ASTM standards. Let's discuss your specific needs and how our products can enhance your safety program.

Contact 3515 today for a quote and secure durable protection for your team.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What role do wearable inertial sensors play in gait quality research? Elevate High-Performance Footwear Design

- What industries besides construction require durable and protective footwear for women? Key Sectors Explained

- What is the purpose of safety footwear standards like EN ISO 20345? Ensure Worker Safety with Certified Protection

- How do safety shoes prevent Podoconiosis? Essential Barrier Protection for Volcanic Soil Regions

- Why are C-shaped rubber bands and shoe cover designs necessary when integrating industrial safety shoes with exoskeletons?

- What are the advantages of composite toe boots compared to steel toe boots? Lighter, Safer & Metal-Free.

- What type of work shoes are recommended for individuals with flat feet? Find Supportive Footwear for All-Day Comfort

- What standards must safety toe boots meet? Ensure Your Footwear Meets ASTM F2413