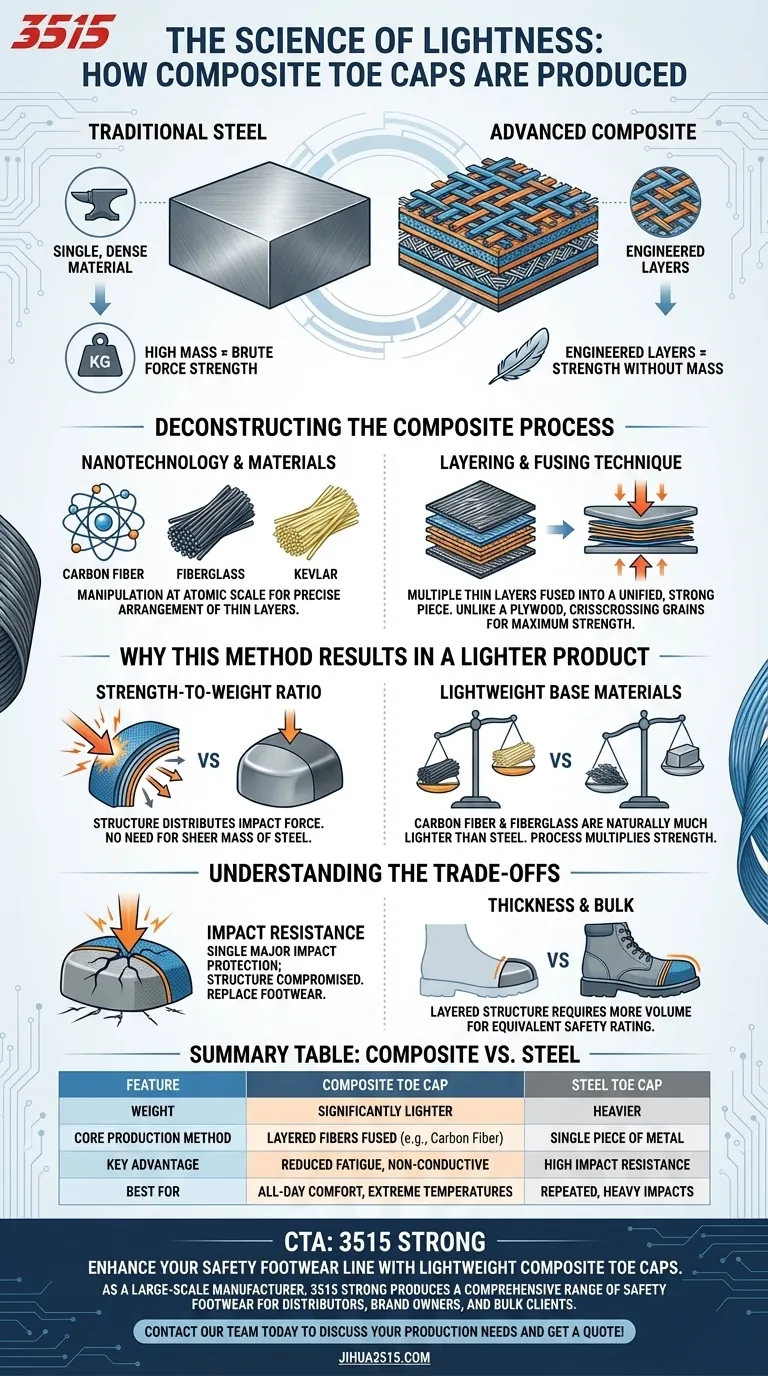

The production process is fundamental to the lightness of composite toe caps. Unlike steel, which is a single, dense material, composites are engineered from multiple thin layers of non-metal fibers fused together, often using advanced nanotechnology, to create a protective cap that is inherently strong yet significantly lighter.

The core principle is simple: instead of relying on the brute-force density of a single material like steel, the composite process builds strength through a sophisticated, layered structure. This allows for robust protection without the associated weight penalty.

Deconstructing the Composite Production Process

The term "composite" itself means something made from several different parts or elements. In the context of safety footwear, this means creating a toe cap not from a solid block of material, but by combining specific materials in a highly controlled way to achieve a desired outcome: high strength and low weight.

The Role of Nanotechnology

At the heart of modern composite manufacturing is nanotechnology. This involves manipulating materials at an atomic and molecular scale.

Instead of just mixing materials, nanotechnology allows for the creation of extremely thin, precisely arranged layers of fibers. These fibers can be carbon fiber, fiberglass, Kevlar, or other advanced polymers.

The Layering and Fusing Technique

The production process involves taking these thin layers of fiber and fusing them together under high pressure and heat.

This fusion creates a single, unified piece. The strength doesn't come from any one layer but from the combined, synergistic effect of all the layers working together. Think of it like a sheet of plywood, where thin, weak layers of wood become incredibly strong when bonded together with their grains crisscrossing.

Why This Method Results in a Lighter Product

The efficiency of the composite method allows it to achieve safety standards with less material density compared to traditional alternatives.

Strength Without Mass

The crisscrossing, layered structure of the fibers creates an incredibly high strength-to-weight ratio.

The structure is designed to distribute the force of an impact across the entire cap, preventing penetration. Because the structure itself provides the strength, there's no need for the sheer mass and density required by a steel cap to achieve the same protective rating.

Material Choice is Key

The base materials—like carbon fiber and fiberglass—are naturally much lighter than steel.

The production process simply leverages the inherent properties of these lightweight materials, combining them in a way that multiplies their strength far beyond what a single piece of that material could provide.

Understanding the Trade-offs

While composite toe caps offer a significant weight advantage, it's important to understand the complete picture.

Impact Resistance

After a single, major impact event that reaches the material's limit, the internal structure of a composite cap can be compromised. While it will have protected the wearer, it may not offer the same level of protection against a subsequent impact and the footwear should be replaced.

Steel, by contrast, may dent upon a severe impact but often retains more of its structural integrity for subsequent, lesser impacts.

Thickness and Bulk

To achieve the same safety rating as steel, a composite toe cap often needs to be slightly thicker or bulkier.

The layered structure requires more volume to build the necessary impact resistance. This can sometimes result in a slightly more bulbous toe box area on the footwear compared to an equivalent steel-toed boot.

Making the Right Choice for Your Needs

Selecting the right toe cap depends entirely on your daily work environment and priorities.

- If your primary focus is minimizing daily fatigue: A composite toe cap is the superior choice, as the weight savings reduce strain over a long workday.

- If your primary focus is working in extreme temperatures: Composite materials do not conduct heat or cold, making them far more comfortable in very hot or cold environments.

- If your primary focus is maximum protection against repeated, heavy impacts: A steel toe cap may offer a slight edge in durability after the initial major impact.

Ultimately, understanding how composite materials are constructed reveals why they are not just an alternative to steel, but a purpose-built solution for modern safety needs.

Summary Table:

| Feature | Composite Toe Cap | Steel Toe Cap |

|---|---|---|

| Weight | Significantly Lighter | Heavier |

| Core Production Method | Layered Fibers Fused (e.g., Carbon Fiber) | Single Piece of Metal |

| Key Advantage | Reduced Fatigue, Non-Conductive | High Impact Resistance |

| Best For | All-Day Comfort, Extreme Temperatures | Repeated, Heavy Impacts |

Ready to enhance your safety footwear line with lightweight composite toe caps?

As a large-scale manufacturer, 3515 Strong produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities allow us to expertly manufacture composite toe cap boots that provide superior protection without the weight, reducing fatigue for the end-user.

Let us help you deliver the comfort and safety your customers demand. Contact our team today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What is the importance of slip-resistant outsole technology in high-performance safety footwear? Protect Your Workforce

- When did the development of safety footwear begin and what drove its introduction? The Industrial Revolution's Impact on Worker Safety

- What is unique about a carbon composite toe? Maximum Protection with Minimal Weight

- Are safety shoes worth it? The Critical Investment in Workplace Safety & Foot Health

- What is the core function of an Asset and Service Information System (ASIS)? Optimize Safety Footwear Lifecycles

- What type of footwear is needed for those working in a foundry? Essential Protection for Extreme Heat & Metal Splash

- What is the primary role of industrial safety shoes in the assembly of heavy iron pipes? Protect Against Impact & Puncture

- What are composite-toed shoes and what materials are they made from? Lightweight, Non-Conductive Safety Footwear