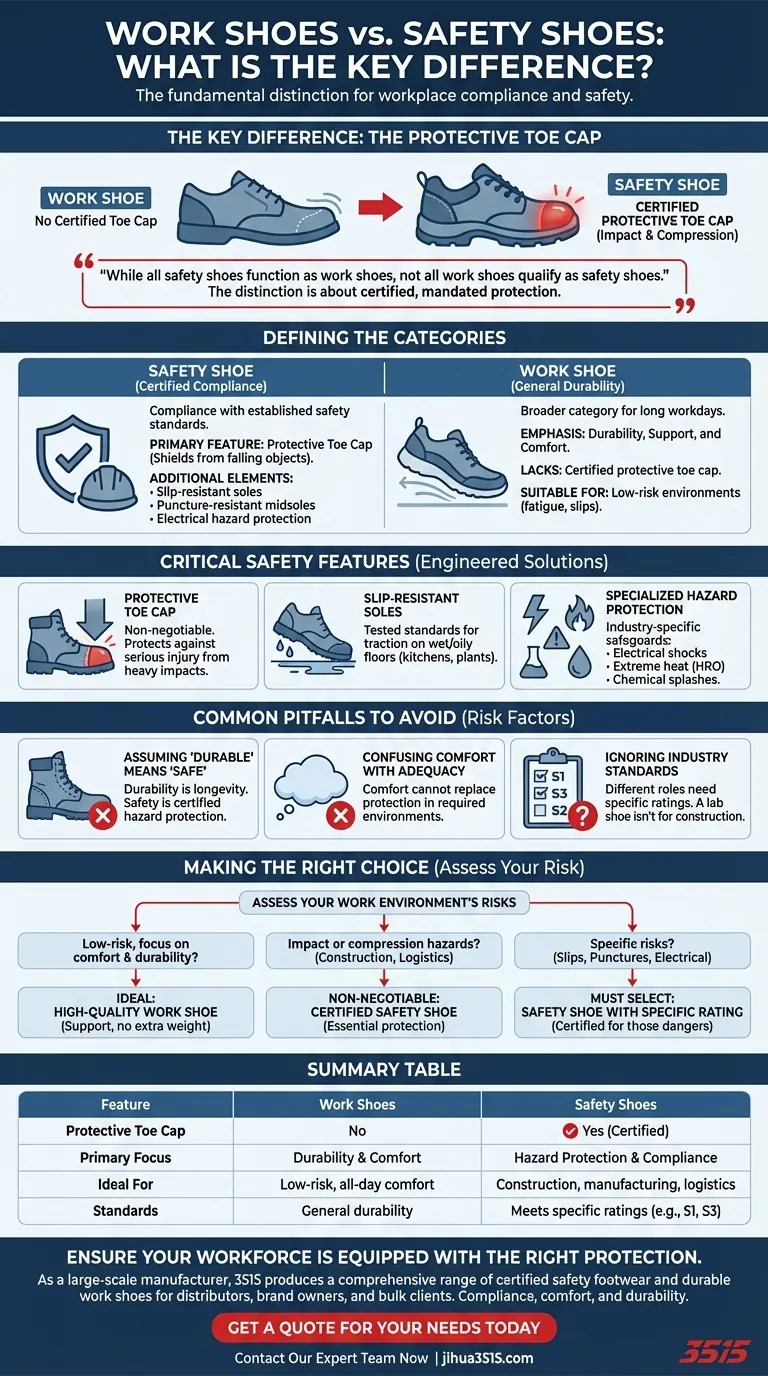

The fundamental difference between work shoes and safety shoes lies in a single, critical feature: the protective toe cap. A true safety shoe is legally required to have a reinforced toe to protect against impact and compression, meeting specific safety standards. General work shoes, while often durable and comfortable for long hours, lack this certified protective element.

While all safety shoes function as work shoes, not all work shoes qualify as safety shoes. The distinction is not about durability or comfort, but about certified, mandated protection against specific workplace hazards.

Defining the Categories: Beyond the Label

Choosing the right footwear requires understanding what each category truly represents. The terms are not interchangeable, and the difference is critical for workplace compliance and personal safety.

What Qualifies as a "Safety Shoe"?

A safety shoe is defined by its compliance with established safety standards. Its primary feature is a protective toe cap designed to shield the foot from falling objects and compression.

Beyond the toe cap, safety shoes often incorporate other protective elements. These can include slip-resistant soles, puncture-resistant midsoles, and protection against electrical hazards.

What Defines a "Work Shoe"?

A "work shoe" is a much broader category. This term typically describes any footwear designed for the rigors of a long workday, emphasizing durability, support, and comfort.

While they are built to be more robust than casual shoes, they do not include a certified protective toe cap. They are suitable for jobs where the primary risks are fatigue or slips, not impact injuries.

Understanding the Critical Safety Features

The specific features of a safety shoe are what set it apart. These are not optional comforts; they are engineered solutions to common workplace dangers.

The Protective Toe Cap: The Core Differentiator

This is the non-negotiable component of a safety shoe. It protects the wearer from serious injury when heavy items are dropped or rolled onto the foot.

Slip-Resistant Soles

While many work shoes offer good traction, safety shoes are often tested to meet specific standards for slip resistance. This is crucial in environments with wet or oily floors, like kitchens or manufacturing plants.

Specialized Hazard Protection

Certain industries require even more specific safeguards. Safety footwear can offer protection from electrical shocks, extreme heat (as seen with an Hro classification for welders), or chemical splashes, depending on the shoe's rating.

Common Pitfalls to Avoid

Misunderstanding the distinction between these shoe types can lead to significant risks. Being aware of common misconceptions is the first step toward making a safe choice.

Assuming "Durable" Means "Safe"

A sturdy leather boot may be durable, but it offers no protection from a heavy impact. Durability is about longevity and wear, while safety is about certified hazard protection.

Confusing Comfort with Adequacy

While modern safety shoes are more comfortable than ever, comfort cannot replace protection. A comfortable work shoe is inadequate and non-compliant in an environment where a safety toe is required.

Ignoring Industry-Specific Standards

The term "safety shoe" is not a monolith. Different industries require different levels of protection, often designated by ratings like S1, S1P, or S3. A shoe suitable for a chemical lab may be insufficient for a construction site.

Making the Right Choice for Your Role

Selecting the correct footwear is a critical decision based on a simple assessment of your work environment's risks.

- If your primary focus is comfort and durability in a low-risk environment: A high-quality work shoe is your ideal choice, as it provides support without the added weight and rigidity of a safety toe.

- If you work in an environment with impact or compression hazards (e.g., construction, logistics, manufacturing): A certified safety shoe is non-negotiable and essential for your protection.

- If your role involves specific risks like slips, punctures, or electrical hazards: You must select a safety shoe with the specific rating that is certified to protect against those dangers.

Ultimately, choosing your footwear is an investment in your personal safety and professional performance.

Summary Table:

| Feature | Work Shoes | Safety Shoes |

|---|---|---|

| Protective Toe Cap | No | Yes (Certified) |

| Primary Focus | Durability & Comfort | Hazard Protection & Compliance |

| Ideal For | Low-risk environments, all-day comfort | Construction, manufacturing, logistics |

| Standards | General durability | Meets specific safety ratings (e.g., S1, S3) |

Ensure your workforce is equipped with the right protection.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear and durable work shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective and occupational footwear, ensuring compliance, comfort, and durability.

Get a quote for your specific needs today and let us help you protect your most valuable asset—your people.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Premium Wheat Nubuck Safety Shoes for Bulk Distribution

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data