At their core, the main difference between composite toe and steel toe shoes is the material used for the protective cap. Steel toe caps are made from heavy-duty steel for maximum impact resistance, while composite toe caps are crafted from non-metallic materials like carbon fiber, Kevlar, or plastic to provide a lighter, non-conductive alternative.

The decision is not about which material is universally better, but about identifying the specific hazards of your environment. Steel offers the highest level of protection against impact, while composite offers superior comfort and performance in specialized conditions involving electricity or metal detectors.

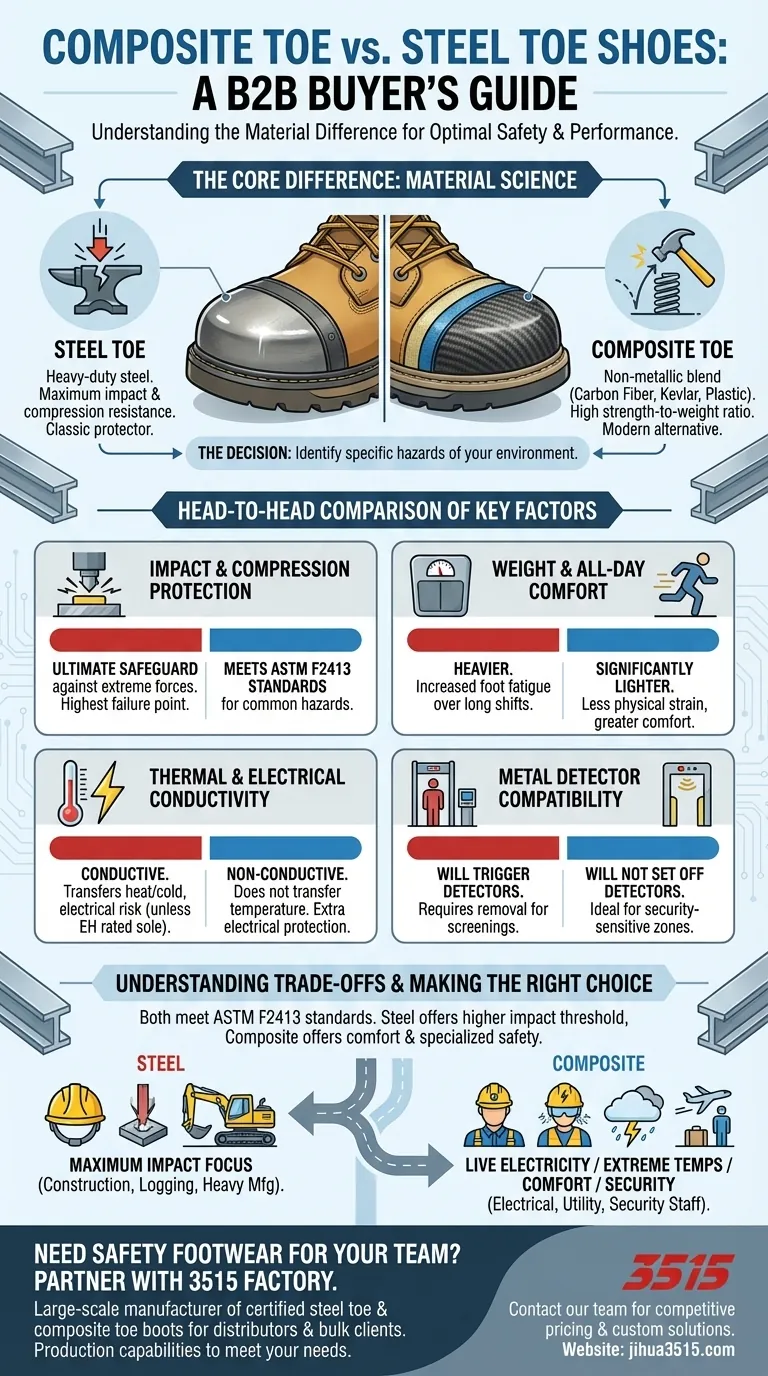

The Core Difference: Material Science

Understanding the material of the protective toe cap is the first step in choosing the right safety footwear. Each material has inherent properties that dictate its performance and ideal use case.

Steel Toe: The Classic Protector

A steel toe cap is the traditional standard for safety footwear. It is a piece of heavy-duty steel shaped to cover the toe area, providing exceptional protection.

This material excels at resisting high-impact and compression forces, making it the benchmark for physical safety in demanding environments.

Composite Toe: The Modern Alternative

A composite toe cap is made from a blend of non-metallic materials. These can include carbon fiber, specialized plastics, fiberglass, or Kevlar.

The primary advantage of these materials is their high strength-to-weight ratio. They provide certified protection without the weight and conductivity of metal.

A Head-to-Head Comparison of Key Factors

While both options are designed to protect you, they offer very different advantages and disadvantages depending on the performance metric.

Impact & Compression Protection

Steel toe shoes offer the highest level of resistance to crushing and impact hazards. If your work involves the risk of extremely heavy objects falling or rolling, steel provides the ultimate safeguard.

Composite toes meet the same ASTM safety standards as steel toes for most common hazards, but steel has a higher ultimate failure point against extreme forces.

Weight and All-Day Comfort

Composite toe shoes are significantly lighter than their steel counterparts. This weight reduction minimizes foot fatigue over a long workday, making them a preferred choice for those who are constantly on their feet.

The lighter weight translates directly to greater comfort and less physical strain at the end of the day.

Thermal & Electrical Conductivity

This is a critical differentiator. As a metal, steel readily conducts heat, cold, and electricity. This can be uncomfortable in extreme temperatures and a serious risk in electrical environments.

Composite toe caps are non-conductive. They do not transfer cold or heat to your feet and provide an extra layer of protection against electrical hazards, making them ideal for electricians or utility workers.

Metal Detector Compatibility

Because they are non-metallic, composite toe shoes will not set off metal detectors. This is a massive advantage for workers in security-sensitive fields, such as airport staff, law enforcement, or employees at secure facilities.

Steel toes will reliably trigger these detectors, requiring removal of the footwear during security screenings.

Understanding the Trade-offs

Choosing safety footwear involves balancing competing priorities. There is no single "perfect" shoe, only the best option for a specific set of risks and requirements.

The Myth of "Less Safe"

It's a common misconception that composite toes are inherently unsafe. Both steel and composite toe footwear must meet the same minimum ASTM F2413 safety standards for impact and compression resistance to be sold as protective footwear.

The key difference is that steel can withstand a higher level of force beyond the standard, making it the choice for the highest-risk environments.

The Bulk Factor

To achieve the required safety rating, a composite toe cap must often be slightly thicker or bulkier than a steel one. This can sometimes affect the profile and fit of the shoe, making it feel more spacious in the toe box.

The Conductivity Nuance

While steel is conductive, many steel toe boots are Electrical Hazard (EH) rated. This rating comes from the insulating properties of the sole and overall boot construction, not the toe cap itself. However, for those working directly with live circuits, a non-conductive composite toe provides a more fundamental layer of safety.

Making the Right Choice for Your Work Environment

Your personal safety depends on matching your footwear's features to your job's specific demands.

- If your primary focus is maximum impact protection (e.g., construction, logging, heavy manufacturing): A steel toe is the superior choice for its ability to withstand extreme forces.

- If your primary focus is working around live electricity or in extreme temperatures: A composite toe's non-conductive properties provide a critical safety and comfort advantage.

- If your primary focus is all-day comfort and avoiding fatigue: A composite toe is significantly lighter, making it the better option for long shifts on your feet.

- If you frequently pass through metal detectors: A composite toe is the only practical option to avoid the daily hassle of security checks.

Ultimately, the best safety shoe is the one that correctly addresses the most significant risks you face each day.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Material | Heavy-duty steel | Non-metallic (carbon fiber, Kevlar, plastic) |

| Best For | Maximum impact protection (e.g., construction) | Electrical work, extreme temperatures, comfort |

| Weight | Heavier | Lighter, reduces fatigue |

| Conductivity | Conducts heat, cold, and electricity | Non-conductive |

| Metal Detectors | Will set off detectors | Will not set off detectors |

| Safety Standards | Meets/exceeds ASTM F2413 standards | Meets ASTM F2413 standards |

Need Safety Footwear for Your Team? Partner with 3515 Factory.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the ultimate protection of steel toe or the specialized benefits of composite toe boots, we have the production capabilities and expertise to meet your needs.

Contact our team today for competitive pricing, custom solutions, and reliable supply.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- How does an alloy toe compare to a steel toe? Lighter Weight, Same Protection

- What's the difference between safety toe and steel toe? Choose the Right Protective Footwear.

- What common myth about steel toe caps is addressed in the article? Debunking the Amputation Fear

- How do safety boots provide toe protection? A Guide to Steel vs. Composite Caps

- What are the differences between steel and composite toe caps? Choose the right protection for your job.

- What are the key features of steel toe footwear? Maximum Impact Protection for Demanding Work

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?

- How do steel toe boots compare to composite toe boots in terms of protection? A Guide to Maximum Safety & Comfort