At their core, steel toe caps provide traditional, heavy-duty impact protection at a lower cost, while composite toe caps offer a modern, lightweight alternative that does not conduct electricity or temperature. Both types of safety caps must pass the exact same ASTM safety standards for impact and compression resistance, ensuring a certified baseline of protection.

The decision between steel and composite is not about which is inherently "safer," but about which material's properties best match the specific hazards and demands of your work environment. The key trade-offs are weight, conductivity, and cost.

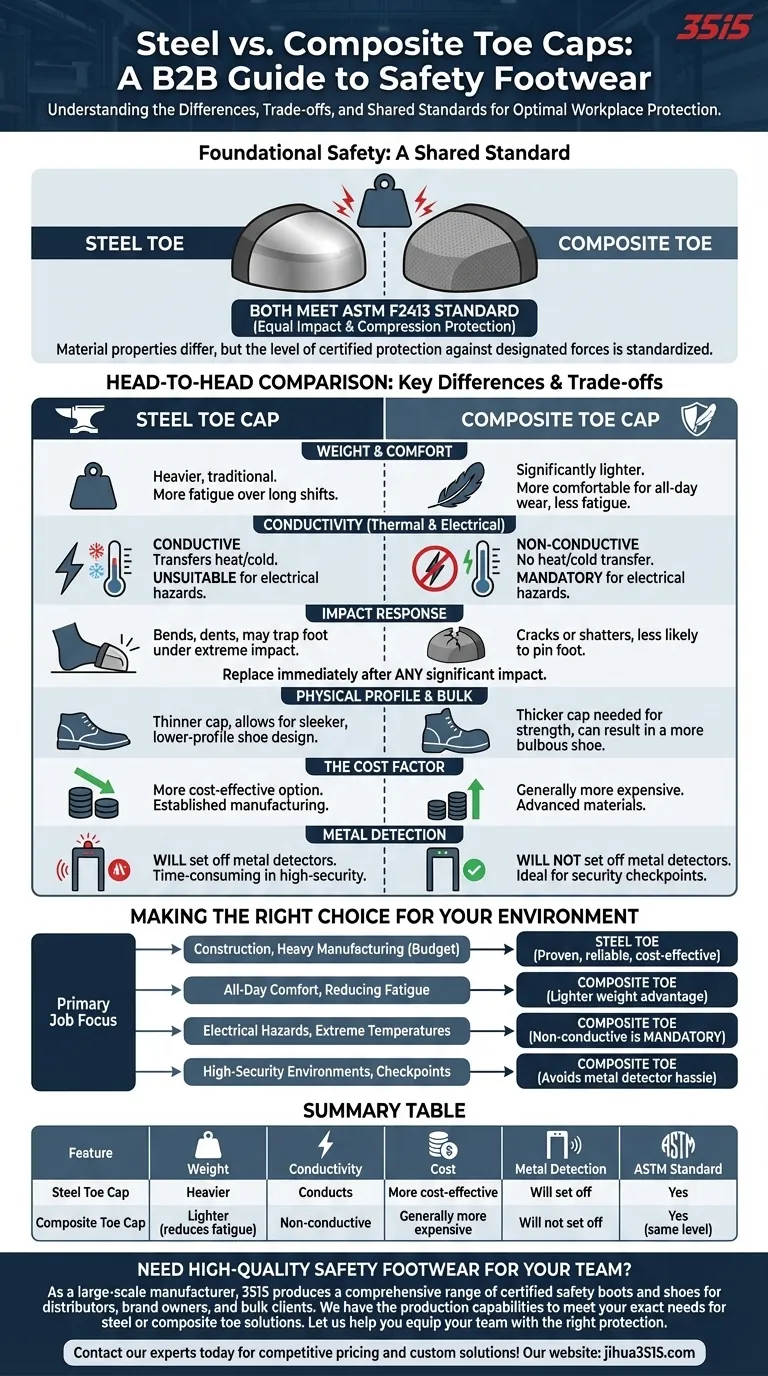

Foundational Safety: A Shared Standard

Before comparing differences, it's crucial to understand what is the same. All legitimate safety footwear in the United States, whether steel or composite, is held to the same performance requirements.

The ASTM F2413 Benchmark

Both steel and composite toe caps must meet the ASTM F2413 standard. This test specifies the required performance for impact and compression resistance.

This means a certified composite toe shoe has successfully proven it can protect your feet from the same designated force as a certified steel toe shoe. The material is different, but the level of protection is standardized.

Key Differences: A Head-to-Head Comparison

The choice between steel and composite comes down to the unique properties of their materials, which create distinct advantages in different situations.

Weight and Comfort

Composite toe caps are significantly lighter than steel toe caps. This reduction in weight can lead to less fatigue for workers who are on their feet for long shifts, making them a more comfortable option for all-day wear.

Conductivity (Thermal and Electrical)

This is one of the most critical differentiators. Steel is a conductor. It will transfer cold in freezing environments and heat in hot environments directly to the foot. Critically, it also conducts electricity, making it unsuitable for electricians or those working near live circuits.

Composite materials are non-conductive. They do not transfer heat, cold, or electricity. This makes them the superior choice for work in extreme temperatures and the mandatory choice for environments with electrical hazards.

Impact Response

While both pass the same tests, their materials react differently to extreme impacts. A steel toe cap can bend, dent, or be crushed under a force exceeding its rating, which can potentially trap the foot.

A composite cap may crack or shatter under a similar extreme impact, but it is less likely to remain dented in a way that pins the foot. After any significant impact event, all safety footwear should be replaced immediately, regardless of material.

Physical Profile and Bulk

To achieve the required strength, composite caps often need to be thicker and more bulbous than their steel counterparts. Steel's inherent strength allows for a thinner cap, which can result in a sleeker, lower-profile shoe design.

Understanding the Practical Trade-offs

Beyond the core material science, practical considerations like cost and workplace rules often guide the final decision.

The Cost Factor

Traditionally, steel toe footwear is the more cost-effective option. The material and manufacturing processes are well-established and generally less expensive than those for advanced composites like carbon fiber or Kevlar.

Metal Detection

Because they contain no metal, composite toe shoes will not set off metal detectors. This is a massive advantage for workers in high-security environments such as airports, nuclear plants, and government buildings, saving them significant time and hassle.

The Myth of "Safer"

Neither material is universally "safer" than the other; they are simply suited for different risks. A steel toe provides reliable, brute-force protection ideal for construction, while a composite toe provides the essential electrical hazard protection an electrician requires. Safety is defined by the context of the job.

Making the Right Choice for Your Work Environment

Your specific job duties and environment should be the ultimate guide in your decision.

- If your primary focus is construction or heavy manufacturing on a budget: Steel toe is the proven, reliable, and cost-effective standard for impact protection.

- If your primary focus is all-day comfort and reducing leg fatigue: Composite toe's lighter weight offers a clear advantage for long shifts.

- If your primary focus is working around electrical hazards or in extreme temperatures: Composite toe is the only appropriate choice due to its non-conductive properties.

- If your primary focus is frequently passing through security checkpoints: Composite toe is essential for avoiding the hassle of metal detectors.

By understanding these core differences, you can select the safety shoe that protects you not just from impact, but from all the specific hazards of your unique workplace.

Summary Table:

| Feature | Steel Toe Cap | Composite Toe Cap |

|---|---|---|

| Weight | Heavier | Lighter, reduces fatigue |

| Conductivity | Conducts heat, cold, and electricity | Non-conductive, safer for electrical work |

| Cost | More cost-effective | Generally more expensive |

| Metal Detection | Will set off metal detectors | Will not set off metal detectors |

| ASTM F2413 Safety Standard | Yes | Yes (same level of protection) |

Need High-Quality Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Whether your workforce requires the cost-effective reliability of steel toe or the lightweight, non-conductive benefits of composite toe, we have the production capabilities to meet your exact needs.

Let us help you equip your team with the right protection.

Contact our experts today for competitive pricing and custom solutions!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- What features make Western work boots suitable for construction sites? Essential Safety & Durability Explained

- What weatherproofing features are available in steel toe boots? Stay Dry & Safe in Any Condition

- What makes moc toe boots suitable for work environments? Unmatched Comfort & Durability

- What materials are used in protective work boots? A Guide to Durability & Safety