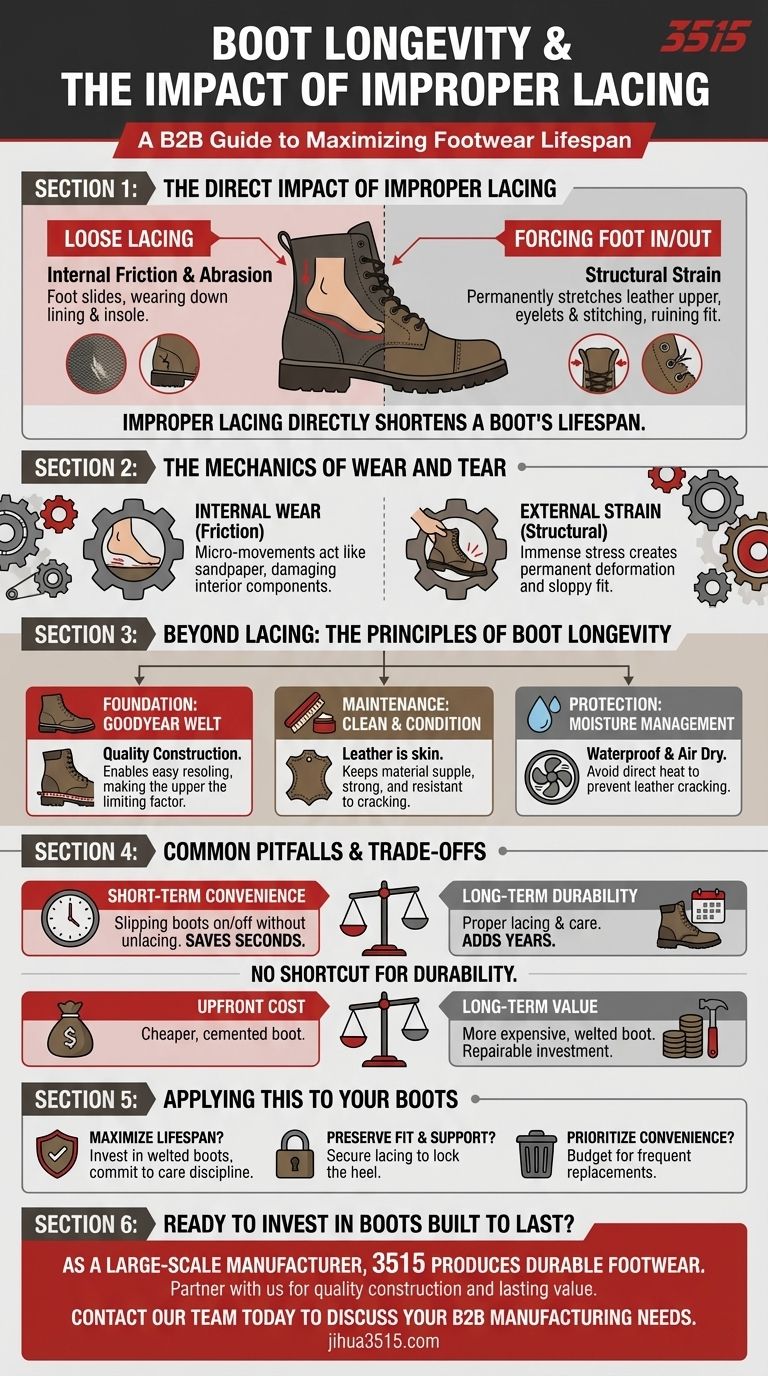

Yes, improper boot lacing directly shortens a boot's lifespan. When laces are too loose, your foot slides, causing friction that wears down the interior lining and insole. Conversely, forcing your foot out of a still-tied boot permanently stretches the leather and compromises the boot's structural integrity, ruining its intended fit and support.

While poor lacing habits cause direct damage, they point to a larger truth: boot longevity isn't about a single trick. It's the result of combining proper daily use with a consistent maintenance routine and investing in a well-constructed boot from the start.

The Mechanics of Wear and Tear

How you lace your boots has a direct, physical impact on their materials. The damage occurs in two distinct ways: internally from friction and externally from structural strain.

Internal Friction and Abrasion

When your boot isn't laced snugly, it fails to lock your heel into the back of the boot. This allows your foot to slide forward and shift with every step.

This constant micro-movement creates friction, which acts like sandpaper on the boot's interior. It wears down the lining, degrades the insole, and can eventually compromise the heel counter, which is critical for support.

Structural Strain on the Upper

The most common and damaging habit is forcing a foot into or out of a boot without untying the laces.

This action places immense stress on the leather upper, the eyelets, and the stitching. Over time, it stretches the leather collar permanently, altering the boot's shape and creating a sloppy fit that can never be recovered.

Beyond Lacing: The Principles of Boot Longevity

Proper lacing is a critical daily habit, but it's only one piece of a larger maintenance strategy. To make boots last for years or even decades, you must address the entire system.

The Foundation of Quality Construction

The single most important factor for a long lifespan is a Goodyear welt. This is a method of construction where the boot's upper is stitched to a strip of leather (the welt), which is then stitched to the sole.

This design makes the boot easily repairable. When the sole wears out, a cobbler can simply cut the old stitches and attach a new sole without deconstructing the entire boot. This makes the boot's upper the limiting factor, not the sole.

Consistent Cleaning and Conditioning

Leather is a skin; it needs to be cleaned and moisturized to stay healthy. Dirt and grime draw moisture out of the leather and act as an abrasive, slowly breaking down the fibers.

Regularly cleaning your boots and applying a quality leather conditioner keeps the material supple, strong, and resistant to cracking.

Moisture Management

Both too much and too little moisture can destroy a boot. Consistently applying waterproofing products helps maintain a barrier against rain and snow.

Equally important is how you store them. Never leave boots to dry near a direct heat source, as this will crack the leather. Let them air dry in a cool, ventilated area.

Common Pitfalls to Avoid

Understanding the common mistakes is key to preserving your investment. The primary trade-off you make is always between short-term convenience and long-term durability.

Convenience vs. Durability

The habit of slipping boots on and off without unlacing is a clear choice. You are trading 15 seconds of your time for months or even years of the boot's structural life. There is no shortcut that doesn't cause damage.

Upfront Cost vs. Long-Term Value

A cheaper boot with a cemented sole is, by design, a disposable item. Once the sole wears through, the boot is finished. A more expensive welted boot is a long-term investment that, with proper care and the occasional resole, can outlast dozens of cheaper pairs.

How to Apply This to Your Boots

Your approach should depend on what you value most in your footwear.

- If your primary focus is maximizing lifespan: Invest in a quality, welted boot and commit to the discipline of proper lacing, cleaning, and conditioning.

- If your primary focus is preserving fit and support: Concentrate on a lacing technique that securely locks your heel in the back of the boot to prevent any internal sliding.

- If your primary focus is daily convenience: Acknowledge that habits like slipping boots on and off will dramatically shorten their life and budget for more frequent replacements.

Proper care transforms your boots from a consumable good into a lasting piece of personal equipment.

Summary Table:

| Impact of Improper Lacing | Consequence |

|---|---|

| Loose Lacing | Internal friction wears down lining and insole. |

| Forcing Foot In/Out | Permanently stretches leather, ruining fit and support. |

| Key for Longevity | Benefit |

| Goodyear Welt Construction | Enables easy resoling, making the boot repairable. |

| Regular Cleaning & Conditioning | Keeps leather supple and strong, preventing cracks. |

| Proper Moisture Management | Protects against damage from both wet and dry conditions. |

Ready to Invest in Boots Built to Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots designed for long-term performance.

Partner with us to offer your customers footwear that combines quality construction with lasting value.

Contact our team today to discuss your manufacturing needs and discover how we can help you build a better product.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What safety features should hazard workers look for in lace-up work boots? A Guide to Certified Protection

- What are the common construction methods for work boots? Choose the Right Build for Your Job

- What is the primary function of specialized rubber safety boots in high-risk autopsies? Ensure Viral Fluid Containment

- How can heavy duty boots be weatherproofed? A Step-by-Step Guide to Lasting Protection

- What are the pros of Goodyear Welt Construction? Unmatched Durability & Resoleability

- How have Western work boots adapted to modern needs? Unpacking the Evolution of Safety and Comfort

- What are the pros of Stitch-down Construction? Unmatched Durability & Support for Your Boots

- How does the design of wildland firefighter boots support comfort and functionality? Engineered for Stability and Endurance