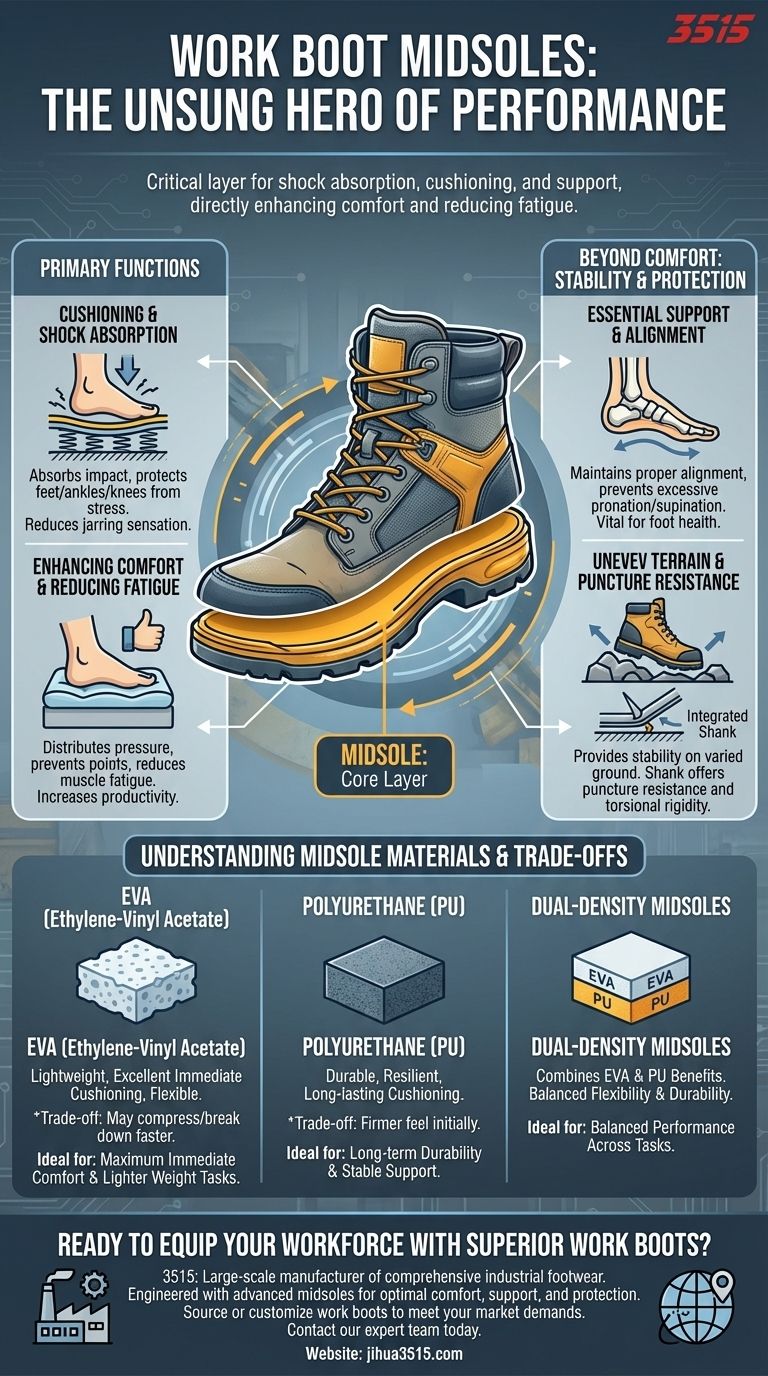

The midsole in work boots primarily serves as the critical layer for shock absorption, cushioning, and support, directly enhancing wearer comfort and reducing fatigue throughout the workday. It acts as a buffer between the foot and the ground, mitigating impacts and providing stability.

The midsole is the unsung hero of work boot performance, directly influencing comfort, safety, and durability. Understanding its construction and materials is key to selecting a boot that genuinely supports and protects your feet against the demands of your environment.

The Fundamental Role of the Midsole

Primary Functions: Cushioning and Shock Absorption

The midsole is essential for absorbing the impact forces generated with each step. This cushioning effect protects the feet, ankles, and knees from undue stress. By dampening shocks, it reduces the jarring sensation experienced on hard surfaces.

Enhancing Comfort and Reducing Fatigue

A well-designed midsole significantly contributes to overall foot comfort. It helps to distribute pressure evenly across the foot, preventing pressure points and reducing muscle fatigue during long hours of wear. This direct impact on comfort keeps workers more productive and less prone to discomfort.

Beyond Comfort: Stability and Protection

Providing Essential Support

Beyond cushioning, the midsole provides crucial support to the foot's arch and structure. This support helps maintain proper foot alignment, preventing excessive pronation or supination. Good support is vital for long-term foot health and stability.

Navigating Uneven Terrain

The midsole's stiffness dictates how well a boot performs on varied ground. A firmer midsole offers greater stability on rocky or uneven surfaces, preventing the foot from twisting. This rigidity helps reduce strain and improves balance in challenging environments.

Integrated Puncture Resistance (Shanks)

Many work boot midsoles incorporate a shank, typically made of steel or composite materials. The shank provides essential puncture resistance, protecting the foot from sharp objects underfoot. It also adds torsional stability, preventing the boot from bending unnaturally.

Understanding Midsole Materials

Different materials are used in midsoles, each offering distinct characteristics:

EVA (Ethylene-Vinyl Acetate)

EVA is lightweight, flexible, and provides excellent immediate cushioning and shock absorption. It offers a comfortable, springy feel. However, EVA can compress and break down over time, leading to a reduction in its cushioning properties.

Polyurethane (PU)

Polyurethane (PU) is denser and more resilient than EVA. It offers superior durability and maintains its cushioning properties for a longer period. While often firmer than EVA, modern PU formulations still provide excellent comfort and support.

Dual-Density Midsoles

Some advanced designs use dual-density midsoles, combining different materials like EVA and PU. This approach leverages the benefits of both, offering a balance of flexibility and long-lasting durability. It allows for targeted cushioning and support where needed.

Understanding the Trade-offs

Choosing a boot often involves balancing different midsole characteristics:

Cushioning vs. Durability

Midsoles that prioritize maximum softness and cushioning (often EVA-based) might wear out faster. Conversely, highly durable midsoles (like PU) may feel firmer initially but offer consistent performance over time. It's a balance between immediate comfort and longevity.

Flexibility vs. Stability

A more flexible midsole allows for greater foot movement, which can be comfortable for walking. However, a stiffer midsole provides superior stability and protection on uneven or hazardous terrain. The required stiffness depends on the work environment.

Making the Right Choice for Your Goal

Selecting the ideal midsole depends entirely on your specific job requirements and personal preferences.

- If your primary focus is maximum immediate comfort and lighter weight: Look for boots featuring EVA midsoles, understanding they may need replacing sooner.

- If your primary focus is long-term durability and stable support: Opt for boots with Polyurethane (PU) midsoles for their resilience and consistent performance.

- If your primary focus is navigating uneven terrain or puncture protection: Prioritize boots with a firmer midsole and a shank for enhanced stability and safety.

- If your primary focus is balanced performance across various tasks: Consider dual-density midsoles that combine the benefits of different materials.

The midsole is a foundational component of work boot performance, directly impacting safety, comfort, and foot health.

Summary Table:

| Midsole Material | Key Characteristics | Ideal For |

|---|---|---|

| EVA (Ethylene-Vinyl Acetate) | Lightweight, excellent immediate cushioning, flexible | Maximum immediate comfort, lighter weight tasks |

| Polyurethane (PU) | Durable, resilient, maintains cushioning over time | Long-term durability, stable support |

| Dual-Density | Combines EVA & PU benefits, balanced flexibility & durability | Balanced performance across various tasks |

| Midsole with Shank | Firm, puncture-resistant, superior torsional stability | Uneven terrain, hazardous environments requiring puncture protection |

Ready to Equip Your Workforce with Superior Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with advanced midsoles for optimal comfort, support, and protection.

Let us help you source or customize work boots that meet the specific demands of your market and end-users. Contact our expert team today to discuss your requirements and discover how we can add value to your supply chain.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What features should workers exposed to chemicals look for in work boots? Essential Guide for Safety

- What are the construction-specific OSHA footwear requirements? Choose the Right Boots for Job Site Safety

- What alternative footwear options are suggested for winter biking? Save Money on Warm Winter Boots

- What is the primary function of specialized rubber safety boots in high-risk autopsies? Ensure Viral Fluid Containment

- What additional safety features do structural firefighting boots provide? Beyond Heat Resistance

- What should be considered for comfort and fit in farming and gardening boots? Ensure Long-Term Endurance

- What are the common types of women's work boots? Find the Right Boot for Your Job's Hazards

- What types of heel designs are found in western work boots? Choose the Right Heel for Your Job