The primary materials used in chemical-resistant boots are specialized polymers like PVC, rubber, and neoprene for the main body, which offer direct protection against corrosive substances. This core defense is supplemented with additional materials like nitrile for outsoles, steel or composite materials for toe protection, and Kevlar thread for durable, chemically-resistant seams.

The key to selecting the right boot is not finding a single "best" material, but understanding that each material offers a specific resistance profile. The goal is to precisely match the boot's composition to the specific chemical hazards of your environment.

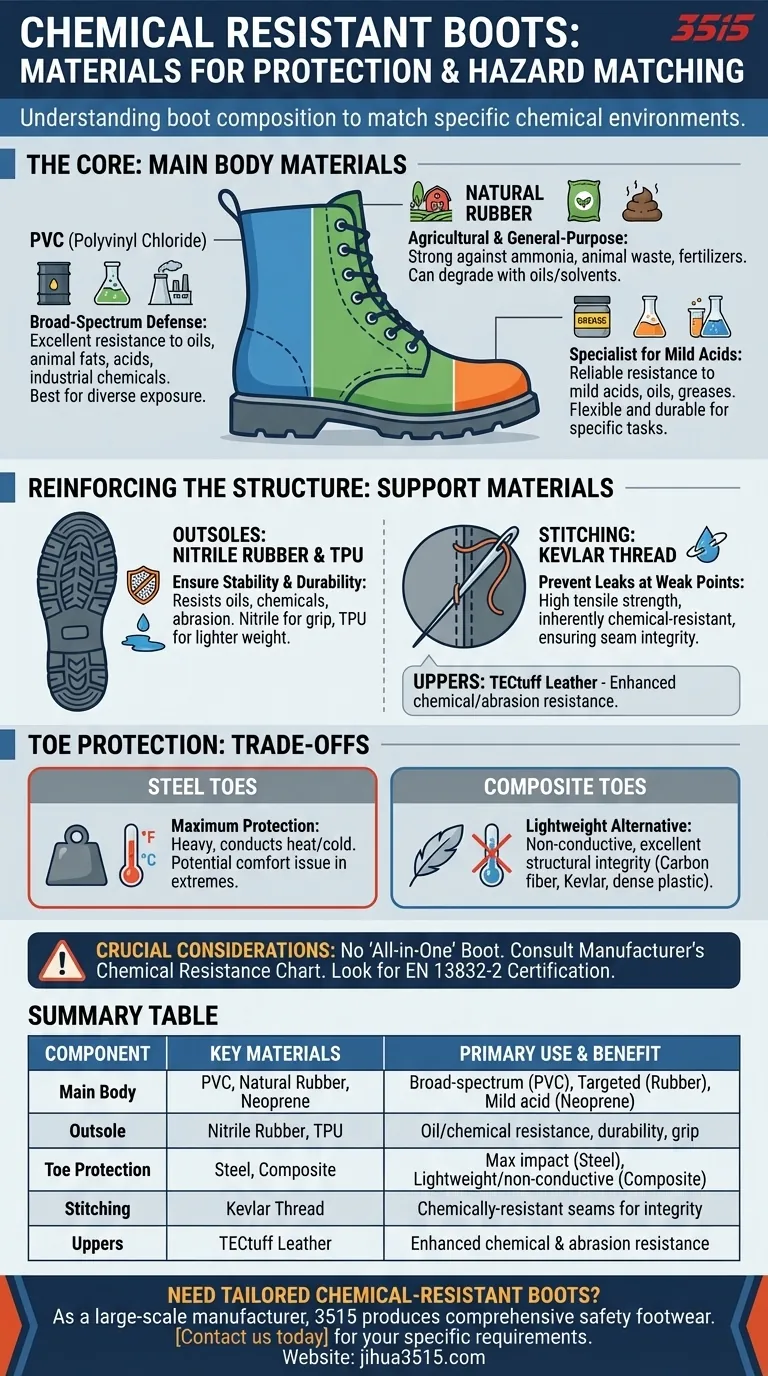

The Core of Chemical Protection: The Boot's Main Body

The main material of the boot provides the first and most critical barrier against chemical exposure. The choice depends entirely on the substances you handle.

PVC (Polyvinyl Chloride): The Broad-Spectrum Defense

PVC is often considered the best all-around material for chemical protection. It provides excellent resistance against a wide array of oils, animal fats, acids, and other industrial chemicals.

This broad resistance makes PVC a common choice for environments with diverse or changing chemical exposures, such as chemical plants and laboratories.

Natural Rubber: The Agricultural & General-Purpose Choice

Rubber offers strong protection against substances like ammonia, animal waste, and fertilizers. This makes it a standard in many agricultural settings.

However, it's important to note that certain oils and solvents can degrade natural rubber over time, making it unsuitable for environments like oil refineries.

Neoprene: The Specialist for Mild Acids

Neoprene provides reliable resistance to mild acids, oils, and greases. It is a flexible and durable material that performs well in specific applications.

It is generally less effective against harsher or more concentrated chemicals, positioning it as a specialized option rather than a general-purpose one.

Reinforcing the Structure: Key Support Materials

Beyond the main shell, several other materials are critical for ensuring the boot's overall integrity and providing comprehensive safety.

Outsoles: Ensuring Stability and Durability

The outsole must resist both chemical attack and physical abrasion. Nitrile rubber is a common choice for outsoles due to its excellent resistance to oils and chemicals, preventing degradation and maintaining grip.

Other materials like thermo-polyurethane (TPU) are also used for their durability and lighter weight.

Stitching: Preventing Leaks at Weak Points

A boot is only as strong as its seams. To prevent chemical ingress through stitching, high-performance boots use thread made from materials like Kevlar aramid fibre.

This thread offers exceptional tensile strength and is inherently resistant to chemical attack, ensuring the boot's construction does not become a failure point.

Uppers: Balancing Protection and Wearability

In some designs, the upper portion of the boot may combine polymers with other materials. TECtuff leather, for example, is a specially treated leather designed to offer enhanced resistance to chemicals and abrasions compared to standard leather.

Understanding the Trade-offs

Selecting the right boot requires acknowledging that every material choice involves a trade-off between protection, weight, and user comfort.

Toe Protection: Steel vs. Composite

Protective toe caps are crucial for preventing impact and compression injuries.

- Steel toes offer maximum protection but are heavy and conduct heat and cold, which can be a significant comfort issue in extreme temperatures.

- Composite toes, made from materials like carbon fiber, dense plastic, or Kevlar, are much lighter and do not conduct temperature. They provide excellent structural integrity, making them a popular modern alternative.

The Myth of the "All-in-One" Boot

No single boot is impervious to all chemicals. A material that is highly resistant to a strong acid may be quickly compromised by a particular solvent.

Always consult the manufacturer’s chemical resistance chart. This documentation specifies which chemicals the boot has been tested against and for how long it can resist penetration.

Beyond the Material: The Importance of Certification

Look for boots that meet recognized safety standards, such as EN 13832-2. This certification indicates that the footwear has been rigorously lab-tested against specific chemicals, providing a verified level of protection you can trust.

Making the Right Choice for Your Environment

Your specific workplace hazards should be the only factor that dictates your choice of boot.

- If your primary focus is working with a wide range of oils, fats, and aggressive chemicals: PVC offers the most robust and broad-spectrum protection.

- If your primary focus is agriculture or environments with ammonia and fertilizers: Natural rubber provides targeted resistance and excellent durability.

- If your primary focus is impact protection without thermal conductivity: Composite toe caps are the superior choice over traditional steel.

- If your primary focus is ensuring structural integrity against harsh use: Look for boots constructed with chemical-resistant thread like Kevlar and durable outsoles made of Nitrile.

Ultimately, a boot’s material specification sheet and its safety certification are your most critical tools for ensuring absolute safety.

Summary Table:

| Boot Component | Key Materials | Primary Use & Benefit |

|---|---|---|

| Main Body | PVC, Natural Rubber, Neoprene | Broad-spectrum chemical resistance (PVC), targeted protection (Rubber), mild acid resistance (Neoprene) |

| Outsole | Nitrile Rubber, TPU | Oil and chemical resistance; durability and grip |

| Toe Protection | Steel, Composite Materials | Maximum impact protection (Steel), lightweight and non-conductive (Composite) |

| Stitching | Kevlar Thread | Chemically-resistant seams for structural integrity |

| Uppers | TECtuff Leather | Enhanced chemical and abrasion resistance |

Need chemical-resistant boots tailored to your specific workplace hazards? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise in materials like PVC, rubber, and neoprene ensures your team gets the precise protection they need. Contact us today to discuss your requirements and benefit from our full-scale production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards

- Why is the use of professional safety shoes critical for injection molding? Prevent Injuries with High-Impact Footwear

- How does the slip resistance of industrial safety shoes protect workers during Genset maintenance? Prevent Oil Slips

- What protective functions do industrial safety shoes provide in petroleum environments? Secure Your Workers' Health