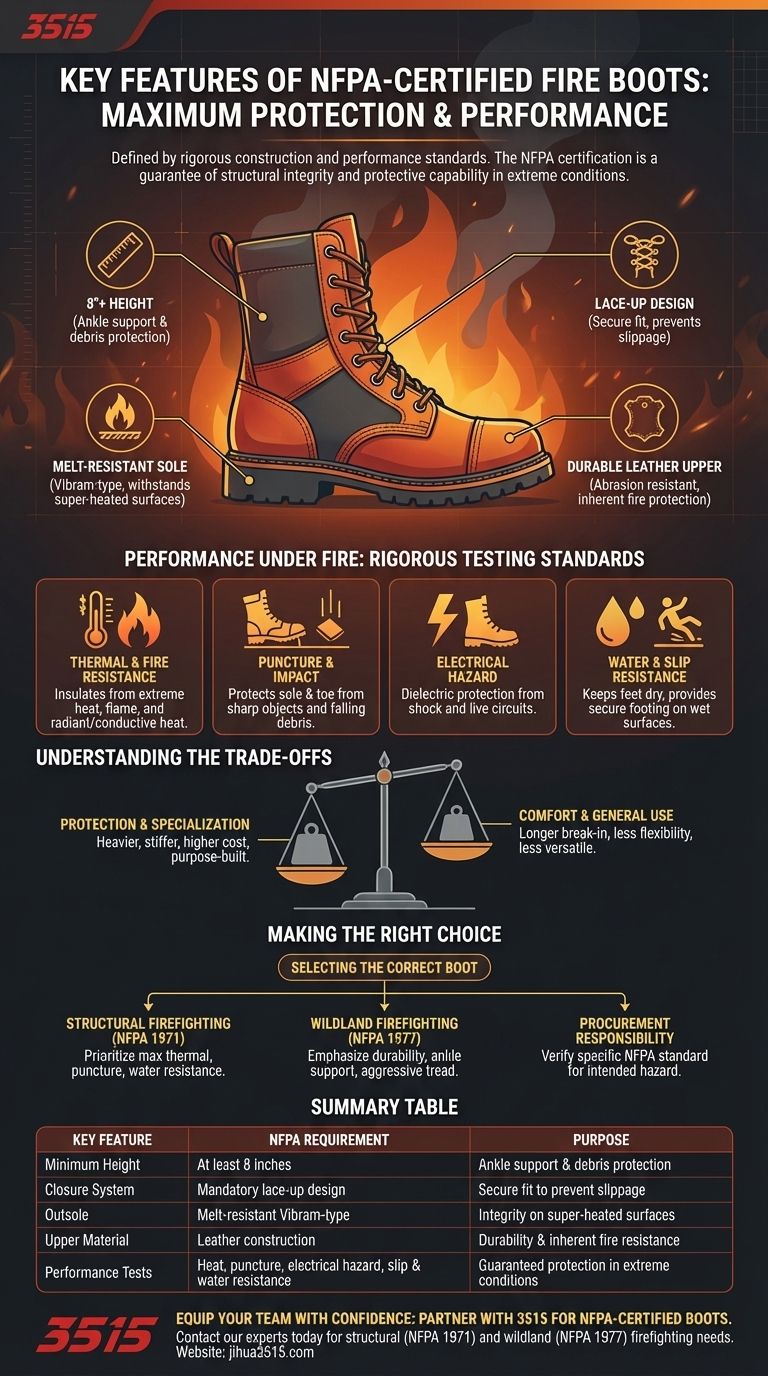

At their core, NFPA-certified fire boots are defined by a specific set of construction and performance standards designed for maximum protection. Key mandatory features include a minimum 8-inch height, a lace-up design, a melt-resistant Vibram-type sole, and a leather exterior, all verified through rigorous testing for heat, puncture, and electrical hazard resistance.

The NFPA certification is not just a label; it is a guarantee that the boot has passed a battery of tests simulating the extreme conditions of firefighting, ensuring its structural integrity and protective capability will not fail when it matters most.

The Foundation of Protection: Core NFPA Requirements

To earn NFPA certification, a fire boot must adhere to a strict set of physical design rules. These requirements form the non-negotiable baseline for firefighter safety and boot performance.

Minimum Height for Support and Coverage

A certified boot must measure at least 8 inches from the bottom of the heel to the top of the boot. This height ensures adequate ankle support and protection from heat and debris, which is critical when navigating unstable environments.

The Lace-Up Mandate for a Secure Fit

The standard explicitly requires boots to be laced. Pull-on styles, such as Wellingtons, are not acceptable for certification. This mandate ensures a consistently snug and secure fit, preventing the boot from slipping or coming off during intense physical activity.

Melt-Resistant Outsoles

The outsole must be a Vibram-type sole engineered to resist melting at high temperatures. This feature is crucial for maintaining the boot's integrity and protecting the firefighter's feet when walking on super-heated surfaces.

Durable Leather Exterior

The boot's upper must be constructed from leather. This material is specified for its natural durability, abrasion resistance, and inherent fire-resistant properties, providing a rugged first line of defense.

Performance Under Fire: Rigorous Testing Standards

Beyond physical construction, the true mark of an NFPA-certified boot is its ability to pass a series of demanding performance tests. These evaluations prove the boot can withstand the hazards firefighters face daily.

Thermal and Fire Resistance

Boots undergo extensive testing to ensure they can insulate the wearer from extreme heat. This includes evaluating their resistance to flame, radiant heat, and conductive heat to prevent burns and maintain structural integrity.

Puncture and Impact Resistance

The sole and toe areas are tested for their ability to protect against punctures from sharp objects like nails and glass. They must also shield the foot from impacts from falling debris.

Electrical Hazard Protection

Certification includes testing the boot's ability to provide protection from electrical shock. The entire boot, especially the sole, is evaluated for its dielectric properties to safeguard against accidental contact with live circuits.

Water and Slip Resistance

To ensure functionality, boots are tested for water penetration resistance to keep feet dry and reduce the risk of steam burns. The outsoles are also evaluated for slip resistance to provide secure footing on wet and unpredictable surfaces.

Understanding the Trade-offs

While NFPA standards maximize safety, it's important to recognize the inherent trade-offs that come with such specialized, high-performance gear.

Protection vs. Comfort

The heavy-duty materials required for protection—such as thick leather and reinforced soles—often result in a stiffer, heavier boot. This can mean a longer break-in period and less flexibility compared to a standard work boot.

Cost vs. Certification

Meeting rigorous NFPA standards requires advanced materials, complex construction, and extensive third-party testing. These factors significantly increase the manufacturing cost, which is reflected in a higher price point for certified boots.

Specialization vs. General Use

These boots are purpose-built tools for firefighting. Their high level of thermal insulation and rigid construction makes them less suitable for general-purpose work or duties outside of an emergency response environment.

Making the Right Choice for Your Role

Selecting the correct boot involves matching its certified capabilities to your specific operational needs.

- If your primary focus is structural firefighting: Prioritize boots certified to NFPA 1971, which guarantees the highest levels of thermal, puncture, and water resistance for interior attack scenarios.

- If your primary focus is wildland firefighting: Look for boots certified to NFPA 1977, which emphasize durability, ankle support, and aggressive tread for long-duration use on uneven terrain.

- If you are responsible for equipment procurement: Always verify the specific NFPA standard the boot is certified for to ensure it is appropriate for the intended hazard exposure of your team.

Understanding these key features ensures you select gear that provides uncompromising protection when confronting the most demanding conditions.

Summary Table:

| Key Feature | NFPA Requirement | Purpose |

|---|---|---|

| Minimum Height | At least 8 inches | Ankle support & debris protection |

| Closure System | Mandatory lace-up design | Secure fit to prevent slippage |

| Outsole | Melt-resistant Vibram-type | Integrity on super-heated surfaces |

| Upper Material | Leather construction | Durability & inherent fire resistance |

| Performance Tests | Heat, puncture, electrical hazard, slip & water resistance | Guaranteed protection in extreme conditions |

Equip Your Team with Confidence: Partner with 3515 for NFPA-Certified Boots

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure your team has access to boots that meet the strictest safety standards for structural (NFPA 1971) and wildland (NFPA 1977) firefighting.

We provide the durable, rigorously tested protection your first responders need. Contact our experts today to discuss your specific requirements and procurement needs.

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How durable are oil resistant safety boots? Built to Withstand Harsh Industrial Environments

- What is the core function of an Asset and Service Information System (ASIS)? Optimize Safety Footwear Lifecycles

- How common are occupational foot injuries? 100,000 Annual Cases Signal a Major Productivity Risk

- What design attributes are required for safety shoes and tactical boots to be compatible with custom orthotics?

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards

- What is the primary function of aramid fiber in protective equipment? Maximize Thermal Stability & Chemical Defense

- How do safety alerts influence footwear replacement in the ACA model? Prioritize Worker Safety with Rapid Risk Response

- What are the two types of electrical protection offered by safety boots? Anti-Static vs. EH Explained