To put it directly, oil-resistant safety boots are engineered for exceptional durability in harsh environments. Unlike standard footwear, every component—from the outsole and upper to the internal linings—is made from specialized materials designed to withstand the degrading effects of oil, chemicals, and solvents without compromising structural integrity.

The true durability of an oil-resistant boot is not a single feature but a complete system. It combines specialized, non-degrading materials with critical safety functions like slip resistance and impact protection to provide reliable, long-lasting safety in hazardous workplaces.

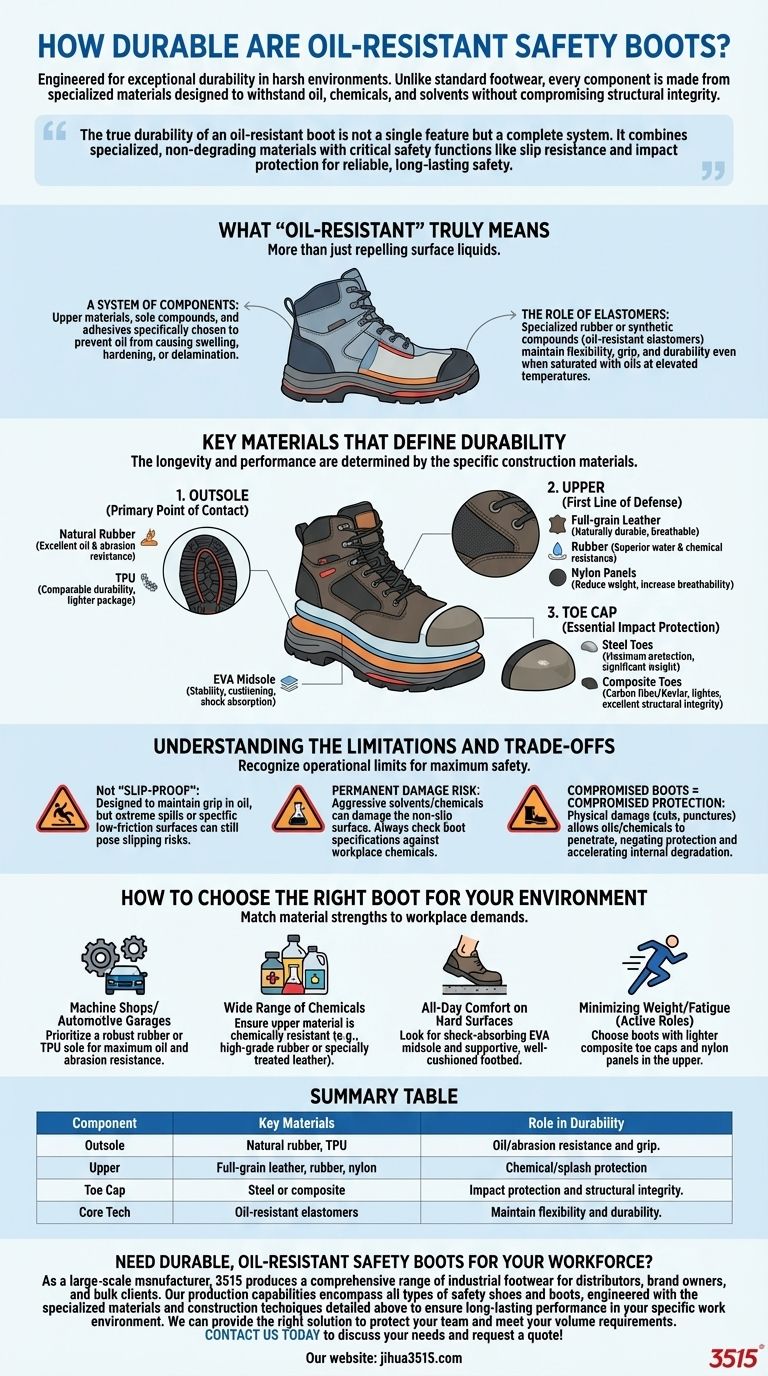

What "Oil-Resistant" Truly Means

The term "oil-resistant" goes deeper than simply repelling surface liquids. It refers to the material's ability to prevent chemical breakdown and maintain its physical properties after prolonged exposure to hydrocarbons.

A System of Components

True oil resistance is a whole-boot characteristic. The upper materials, sole compounds, and even the adhesives used to bond them are chosen specifically to prevent oil from causing them to swell, harden, or delaminate.

The Role of Elastomers

The core technology involves oil-resistant elastomers, typically used in the sole. These specialized rubber or synthetic compounds maintain their flexibility, grip, and durability even when saturated with oils, particularly at the elevated temperatures found in many industrial settings.

Key Materials That Define Durability

The longevity and performance of a safety boot are determined by the specific materials used in its construction. Understanding these is key to selecting the right boot.

The Outsole: Your Primary Point of Contact

The outsole is the most critical component for oil resistance. Common materials include natural rubber, which offers excellent oil and abrasion resistance, and thermo-polyurethane (TPU), which provides comparable durability in a lighter package. Ethylene-vinyl acetate (EVA) is often used in the midsole for its stability, cushioning, and shock absorption.

The Upper: Your First Line of Defense

The upper material must protect against splashes and spills. Full-grain leather is naturally durable and breathable, while specialized rubber uppers offer superior water and chemical resistance. Nylon is often used in panels to reduce weight and increase breathability without sacrificing toughness.

The Toe Cap: Essential Impact Protection

Durability also means impact protection. Steel toes offer maximum protection but add significant weight. Composite toes, made from materials like carbon fiber or Kevlar, provide excellent structural integrity and safety while being much lighter.

Understanding the Limitations and Trade-offs

While highly durable, it is crucial to recognize the operational limits of oil-resistant boots to ensure maximum safety.

"Resistant" Does Not Mean "Slip-Proof"

An oil-resistant sole is designed to maintain its grip and not degrade in oil. However, in environments with extreme spills or specific low-friction surfaces, the risk of slipping can still exist. These boots reduce the risk dramatically but do not eliminate it.

The Risk of Permanent Damage

While resistant to oil, certain aggressive solvents or chemicals can permanently damage the non-slip surface of the outsole. Always check the boot's specifications against the specific chemicals present in your workplace.

Compromised Boots Offer Compromised Protection

Any physical damage, such as a deep cut or puncture in the sole or upper, can create a pathway for oils and chemicals to penetrate the boot. This not only negates its protective qualities but can also accelerate the degradation of internal components.

How to Choose the Right Boot for Your Environment

Your choice should be guided by the specific hazards and demands of your job.

- If your primary focus is working in machine shops or automotive garages: Prioritize a boot with a robust rubber or TPU sole for maximum oil and abrasion resistance.

- If your primary focus is protection from a wide range of chemicals: Ensure the upper material is specified as chemically resistant, such as high-grade rubber or specially treated leather.

- If your primary focus is all-day comfort while standing on hard surfaces: Look for a boot with a shock-absorbing EVA midsole and a supportive, well-cushioned footbed.

- If your primary focus is minimizing weight and fatigue in an active role: Choose boots with lighter composite toe caps and nylon panels in the upper.

Ultimately, selecting the right oil-resistant boot is about matching its specific material strengths to the unique demands of your workplace.

Summary Table:

| Component | Key Materials & Their Role in Durability |

|---|---|

| Outsole | Natural rubber, TPU for oil/abrasion resistance and grip. |

| Upper | Full-grain leather, rubber, nylon for chemical/splash protection. |

| Toe Cap | Steel or composite for impact protection and structural integrity. |

| Core Tech | Oil-resistant elastomers maintain flexibility and durability. |

Need durable, oil-resistant safety boots for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the specialized materials and construction techniques detailed above to ensure long-lasting performance in your specific work environment.

We can provide the right solution to protect your team and meet your volume requirements. Contact us today to discuss your needs and request a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What is the primary ASTM standard for safety footwear? Your Guide to F2413-18 Compliance

- What should employers consider when selecting safety footwear? A Guide to Risk-Based Selection

- How does an industrial-grade zipper strength testing machine ensure the reliability of fire safety boot fastening systems?

- What features should you look for in motorcycle boot soles? Essential Grip, Support & Control

- What are the primary protective functions of industrial safety shoes in pharmaceutical QC labs? Ensure Lab Safety

- Why is the ISO 5349 standard used instead of ISO 2631-1 for high-frequency foot vibration? Protect Your Feet Today

- Why should ergonomics and comfort be prioritized when selecting safety shoes? Boost Compliance & Worker Health

- What are the key ASTM standards for protective footwear compliance? Ensure Workplace Safety & OSHA Compliance